Winding machine for nickel-hydrogen battery

A technology of nickel-hydrogen battery and winding machine, which is applied in the direction of alkaline storage battery, alkaline storage battery manufacturing, sustainable manufacturing/processing, etc. unevenness etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

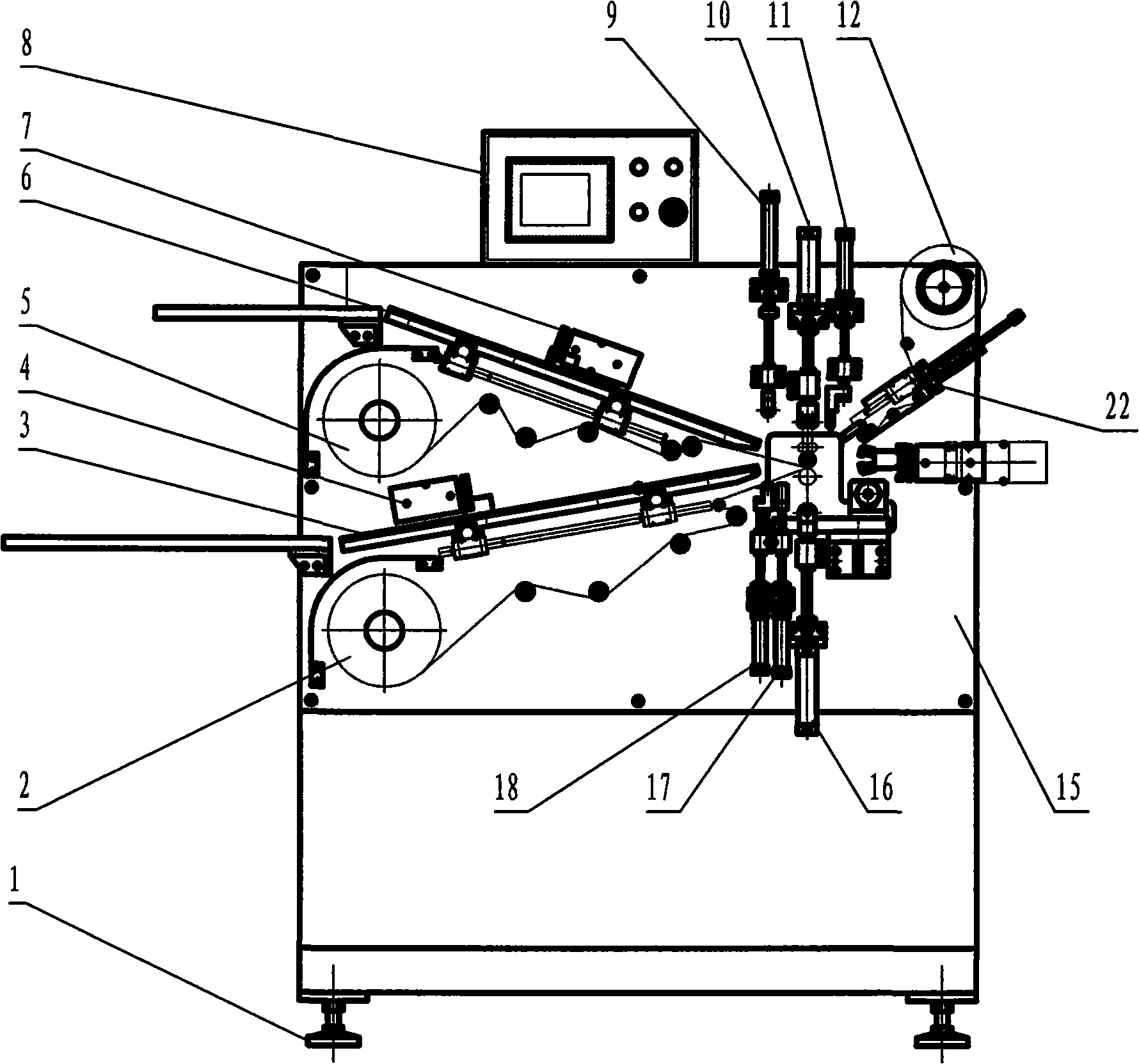

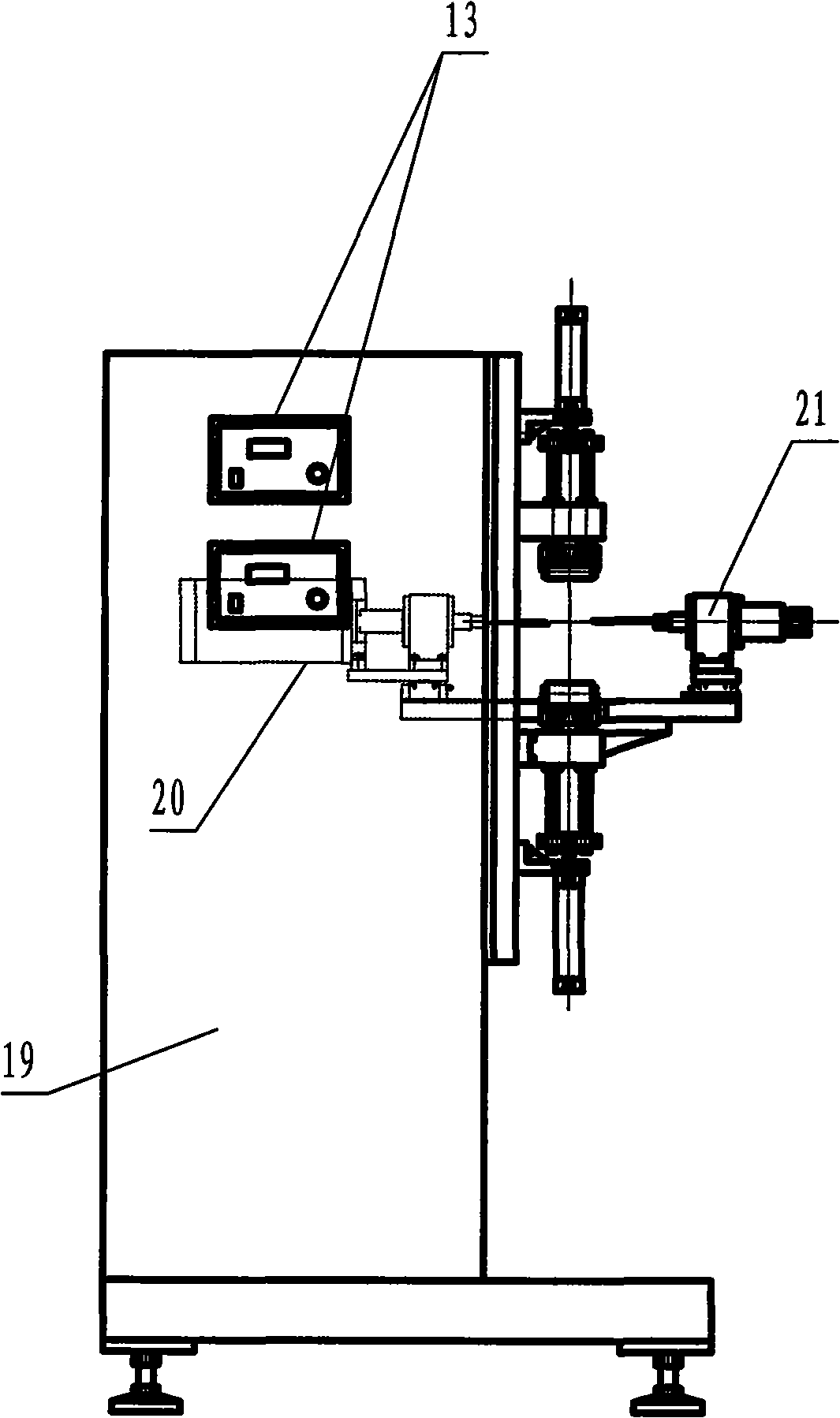

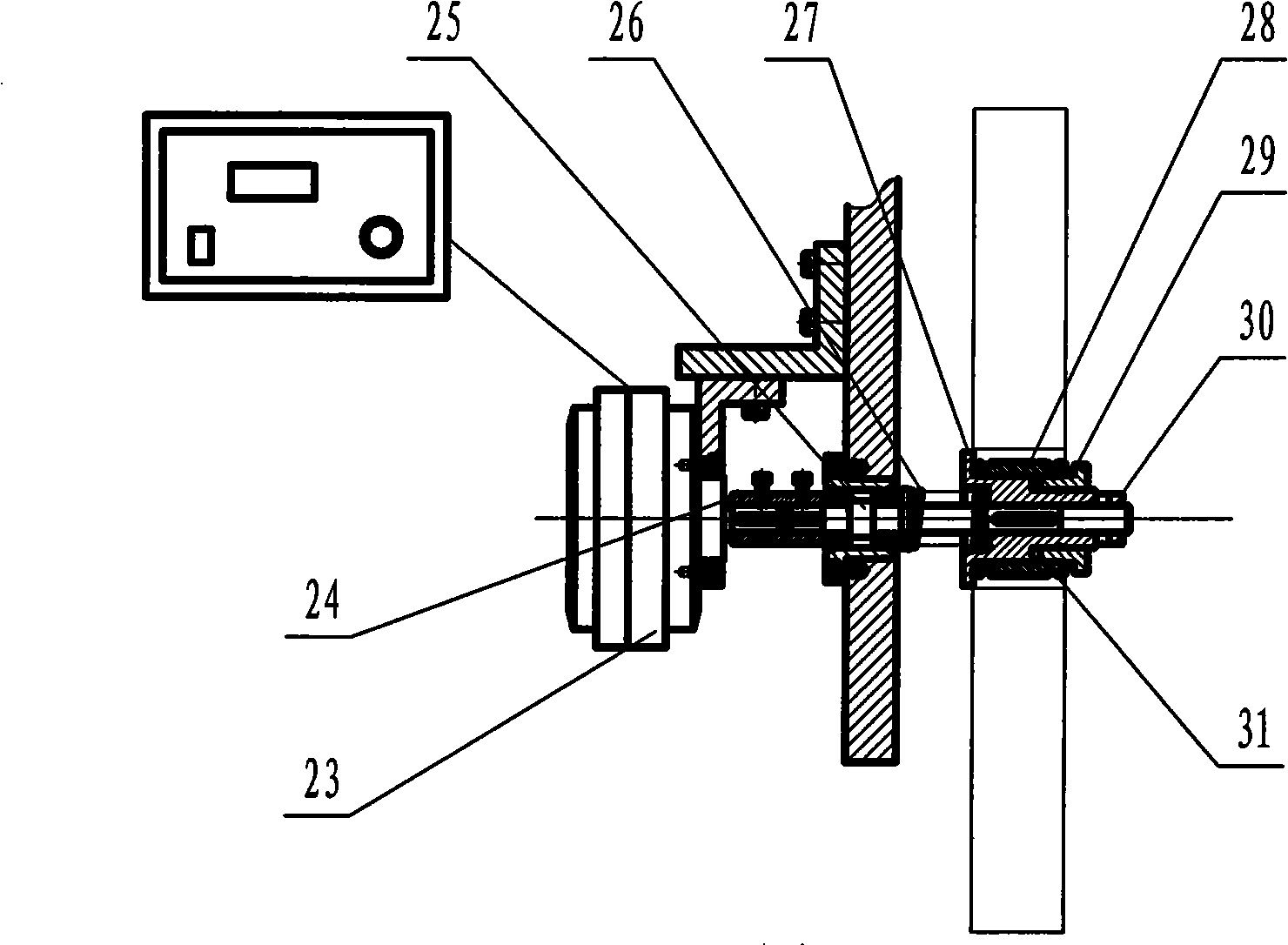

[0018] Such as figure 1 and figure 2 As shown, the nickel-hydrogen battery winding machine of the present invention includes a frame 19 and an equipment substrate 15 fixed on the frame 19. The base of the frame 19 is provided with adjustable feet 1 to adjust the horizontal state of the equipment. The device substrate 15 is provided with a battery plate seat, a diaphragm seat 27, a plate guide mechanism 3, a needle winding mechanism, a diaphragm constant tension control mechanism, a winding constant pressure control mechanism, and a diaphragm grasping mechanism.

[0019] The winding upper pressing mechanism 10, the winding lower pressing mechanism 16, the main needle winding mechanism 20, and the auxiliary needle winding mechanism 21 wind the positive and negative plates and the positive and negative diaphragms into winding batteries 35 according to the battery process requirements; Diaphragm roll 2, positive diaphragm roll 5, upper diaphragm mechanism 9, lower diaphragm mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com