Packaging film with top layer forming a predefined opening track

A technology of packaging film and tear-off layer, which can be used in packaging, wrapping paper, household packaging, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

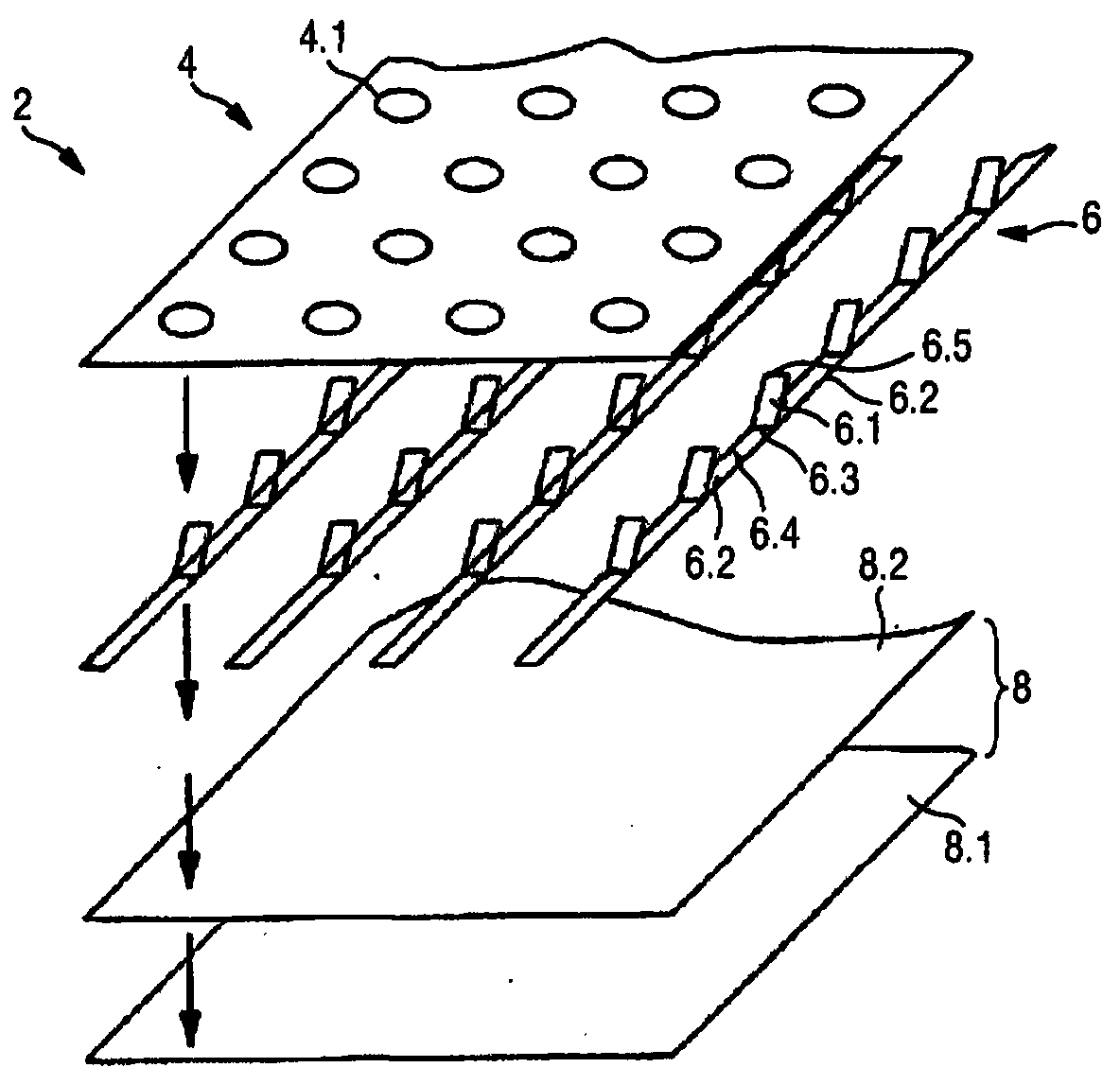

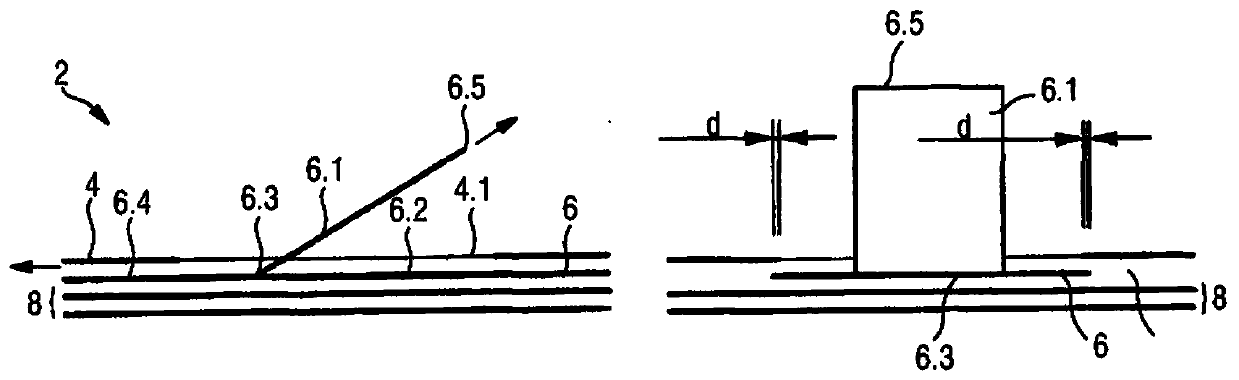

[0046] figure 1 and 2 A first embodiment of the packaging film of the present invention is shown.

[0047] figure 1 An exploded view of the components of the packaging film according to the first embodiment is shown. The packaging film 2 is made of multiple layers. The packaging film 2 comprises a top layer 4 with holes 4.1. The top layer 4 is continuous and preferably non-tearable. It can be die cut by mechanical or laser technology.

[0048] Directly below the top layer 4, a tear-away layer 6 is provided. It consists in this example of a strip comprising a series of pull tabs 6.1 and an elongated portion 6.2 adhered to the bottom layer 8 . Each tab 6.1 forms a hinge 6.3 with a part 6.2. Each portion 6.2 is also transversely weakened 6.4 in order to allow separation of the straps when traction is exerted on the corresponding tab 6.1. Each tab 6.1 may be formed by folding a part of the strip on itself, the free end 6.5 of said tab 6.1 corresponding to the fold of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com