Multiple Disc Clutch

一种多盘式、离合器的技术,应用在离合器、摩擦离合器、流体驱动离合器等方向,能够解决多片式离合器没有适当地通风等问题,达到减少结构要求的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

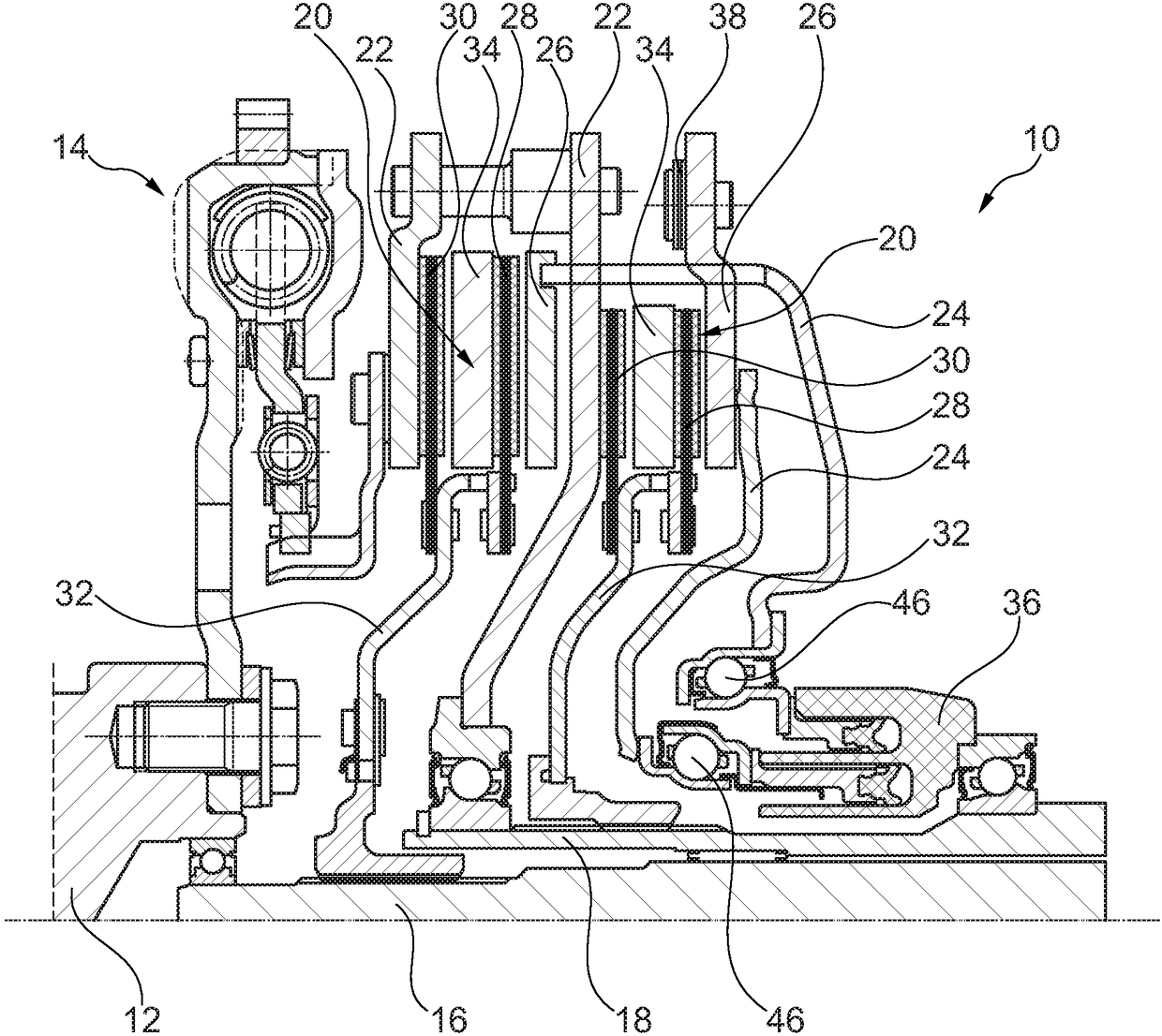

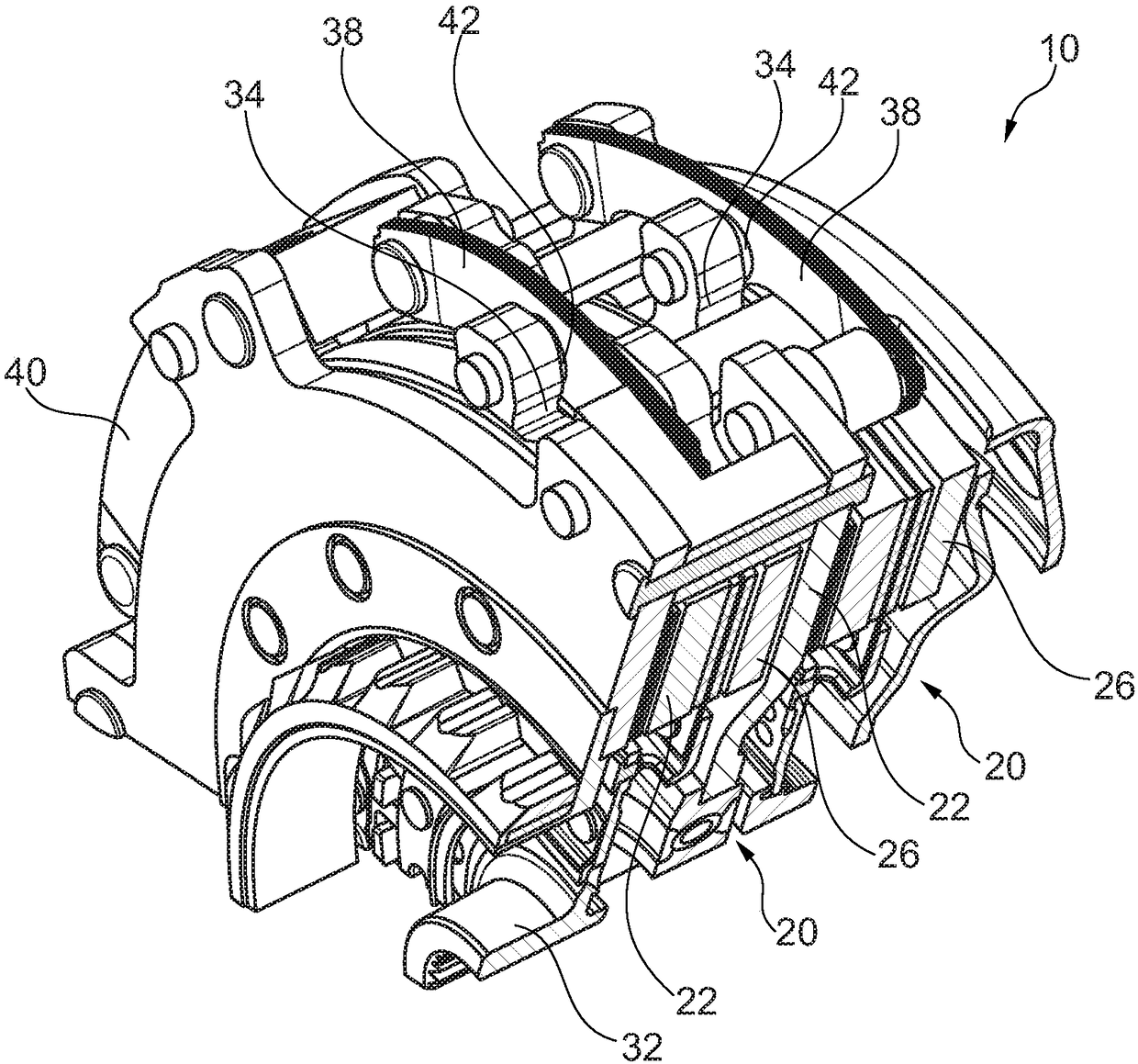

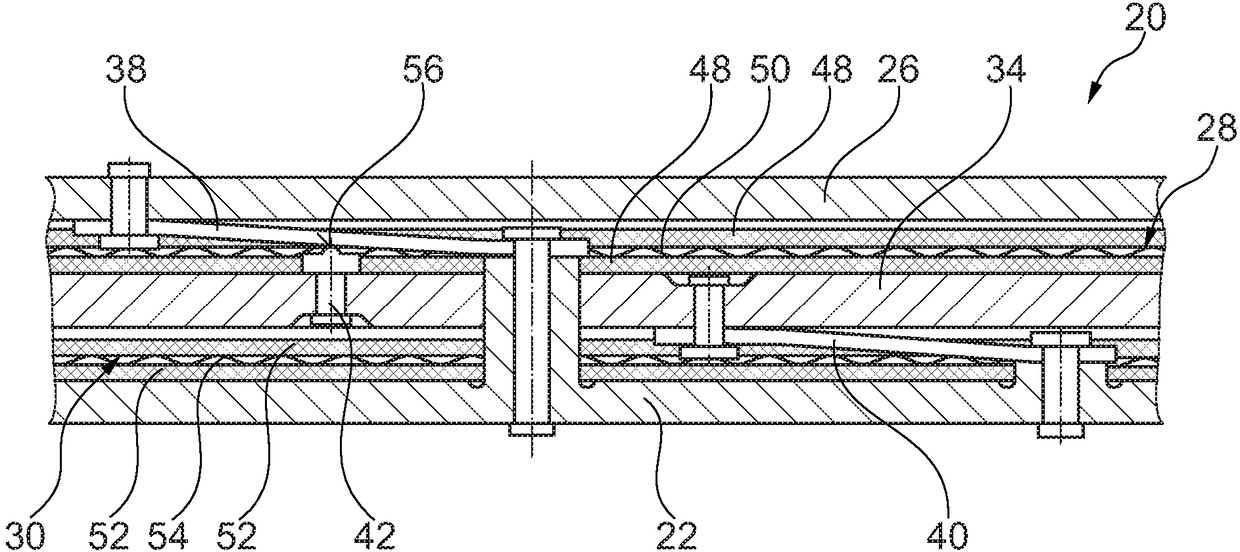

[0051] figure 1 The dual clutch 10 shown in FIG. 2 can decouple a drive shaft 12 from a first transmission input shaft 16 and a second transmission input shaft 18 via a torsional vibration damper 14 designed as a dual-mass flywheel. For this purpose, a multi-disc clutch 20 is provided in each case, each having a corresponding plate 22 coupled to the drive shaft 12 and a pressure plate displaceable by means of an actuating element 24 designed as a rigid actuating pot 26, wherein, the pressing plate 26 can also press the middle plate 34, and the middle plate is arranged between the first lining ring 28 of the clutch disc 32 and the second lining that can move axially relative to the first lining ring 28 Between rings 30. For this purpose, an actuating force, in particular for closing the multidisc clutch 20 , can be introduced into the actuating element 24 by the hydraulic actuating element 36 . The pressure plate 26 is connected at least indirectly to the counter plate 22 via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com