Prefabrication assembly type box culvert prefabrication turnover device and installation method

A prefabricated assembly, box culvert technology, applied in manufacturing tools, auxiliary molding equipment, road bottom and other directions, can solve the problems of structure being easily restricted by the shape of components, prone to safety accidents, low versatility, etc., to reduce the probability of damage, Strong operability and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

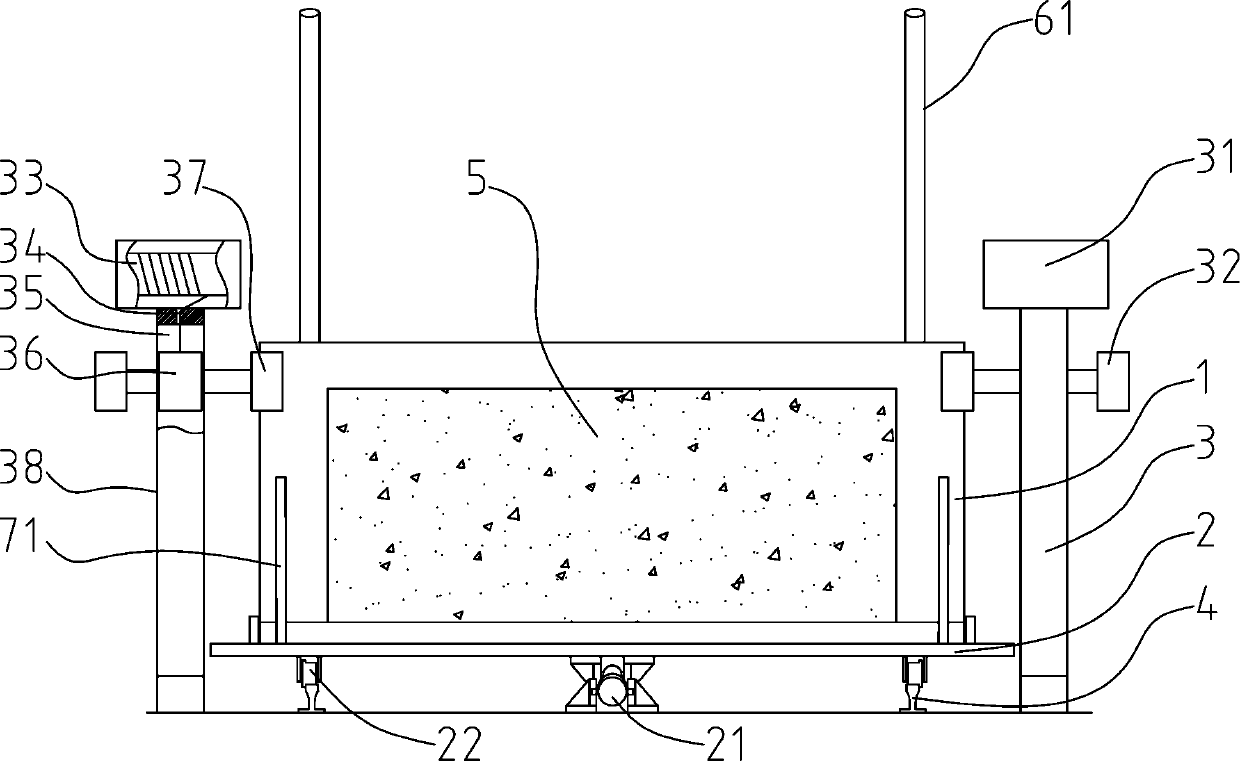

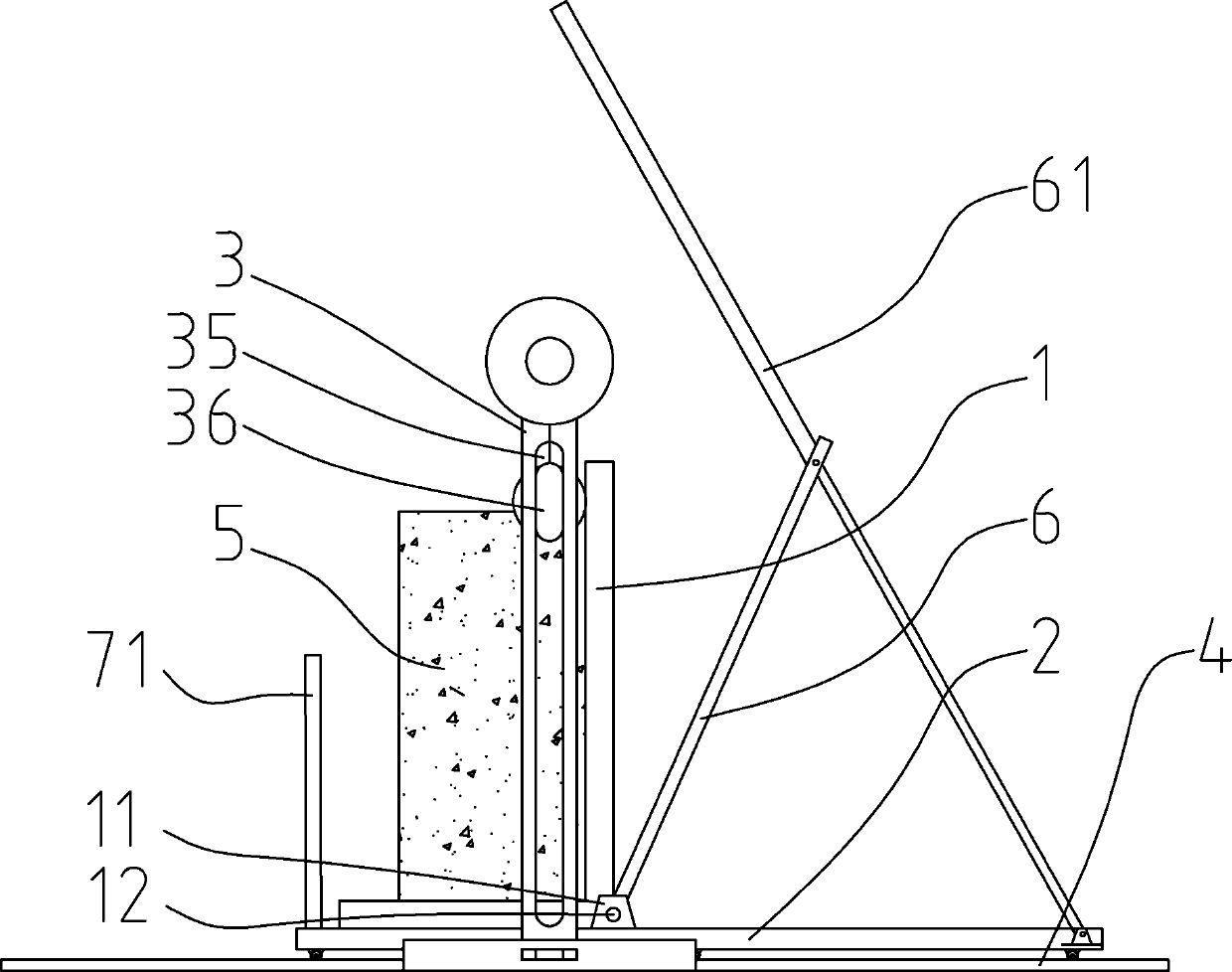

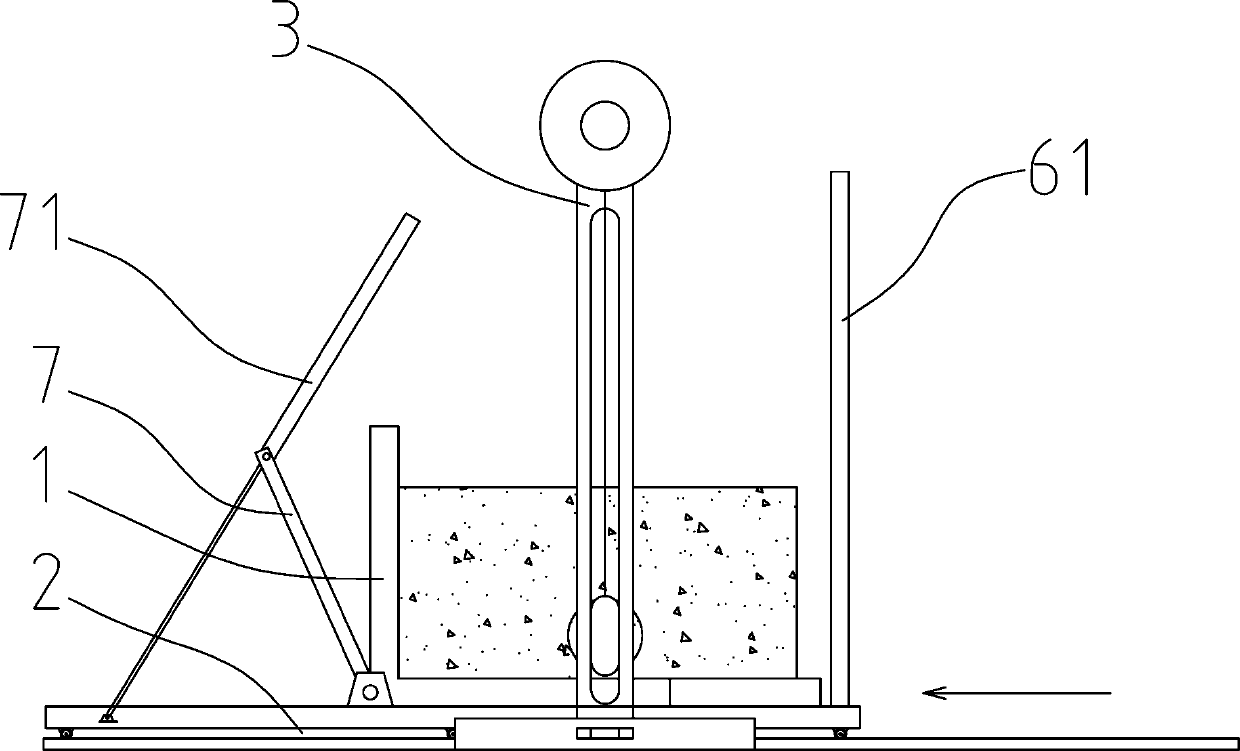

[0060] Such as Figure 1~5 Among them, a prefabricated assembled box culvert prefabricated turning device, which includes a mobile platform 2, a turning platform 1 and a blocking column 3;

[0061] Such as Figure 4 As shown in , the turning platform 1 is in an "L" shape, and the turning point of the turning platform 1 is connected with the mobile platform 2 through the rotating seat 101, and the turning platform 1 is turned with the rotating shaft of the turning seat 101 as the center of the circle;

[0062] Such as Figure 1~3 Among them, the bottom surface of at least one side of the mobile platform 2 is fixed with a blocking column 3, and the blocking column 3 contacts the turning platform 1 through the set blocking wheel 37, and when the moving platform 2 moves, the turning platform 1 is driven by the blocking wheel 37 Flip. From this structure, such as Figure 2~4 As shown in , by driving the movement of the mobile platform 2 and limiting the position of the blocking...

Embodiment 2

[0076] On the basis of Example 1, such as Figure 7 As shown in , an installation method using the above-mentioned prefabricated box culvert prefabricated turn-over device includes the following steps:

[0077] S1, foundation treatment, testing and stakeout;

[0078] Specifically include: construction preparation, foundation pit excavation, foundation leveling treatment, foundation pit bearing capacity test, laying gravel cushion 30, and using total station to test and stake out the entire foundation pit;

[0079] S2, arrange concrete block 8; figure 2 , 3 As shown in , a self-compacting concrete cushion 9 is laid around the concrete pad 8 to prevent the uneven settlement of the components of the prefabricated box culvert 5; the concrete pad 8 is located at the bottom of both ends of the prefabricated box culvert 5. Span between two prefabricated box culverts 5 to ensure that the elevation between the two prefabricated box culverts 5 is consistent.

[0080] S3, making 5 c...

Embodiment 3

[0089] On the basis of Example 2, in a preferred solution, step S3 also includes the following steps:

[0090] S31. Set up the turning platform 1; the structure of the turning platform 1 is as follows Figure 1~5 shown in ; used to realize the 90° flip of the prefabricated box culvert 5.

[0091] S32. Set up a formwork on the turning platform 1; the set up formwork is in the shape of a "back", and the inner mold and the outer mold are positioned by tie screws.

[0092] S33. Hoist the reinforcement cage in the formwork; it must be fixed and reliable during the hoisting process to prevent the deformation of the reinforcement cage during the hoisting process and affect the quality of the finished product.

[0093] S34, pouring concrete, and vibrating and compacting;

[0094] S35, mold removal and maintenance, preferably using a steam shed for maintenance;

[0095] S36. After the maintenance meets the strength requirements, the prefabricated box culvert 5 is turned over 90°;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com