Processing die table of prefabricated panels

A technology for prefabricating wallboards and mold tables, which is applied in the direction of manufacturing tools, mold fixtures, mold auxiliary parts, etc. It can solve the problems that the ground cannot be guaranteed to be absolutely flat, the process of wallboard processing is inconvenient, and the labor intensity of workers is increased. Facilitate processing, reduce labor intensity and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the drawings.

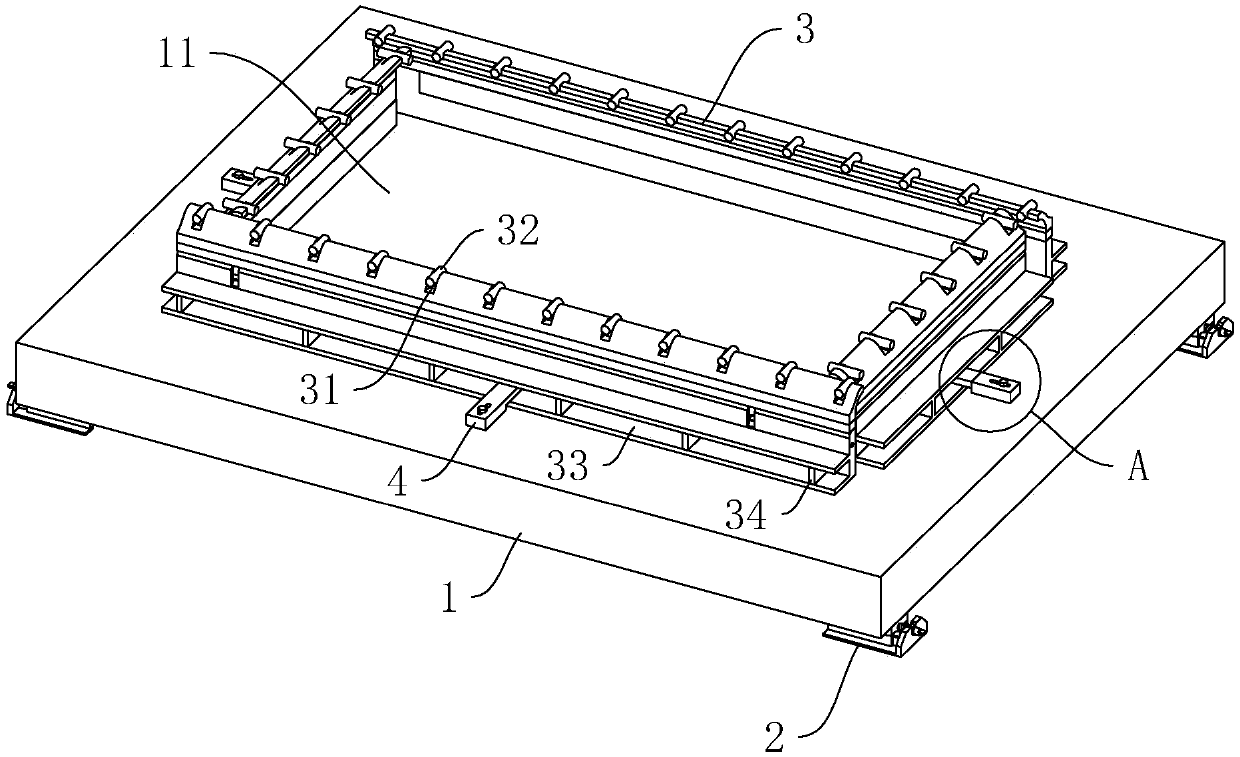

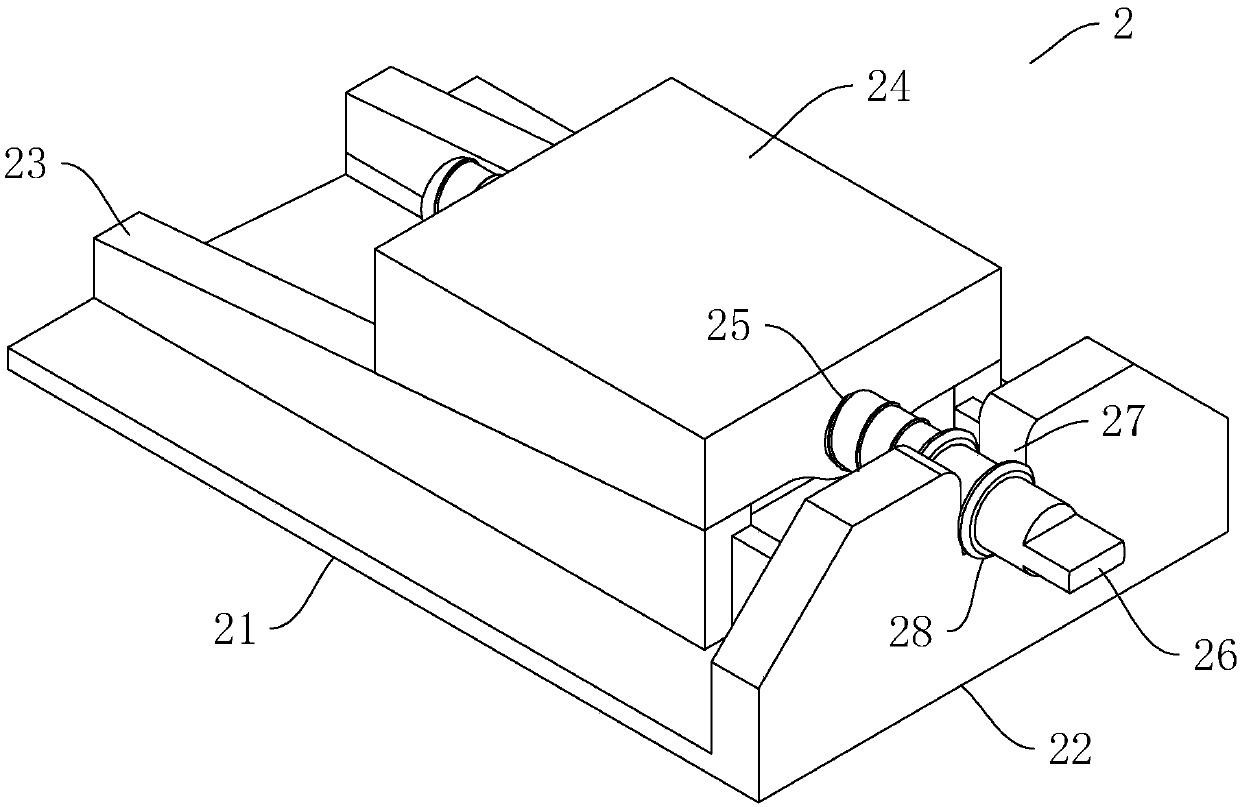

[0036] Such as figure 1 As shown, a processing mold table for prefabricated wall panels includes a base 1, a workbench 11 horizontally arranged on the upper end surface of the base 1, and feet 2 are provided around the lower end of the base 1. A plurality of side mold bars 3 are arranged on the workbench 11, and the side mold bars 3 are connected end to end to form a closed loop.

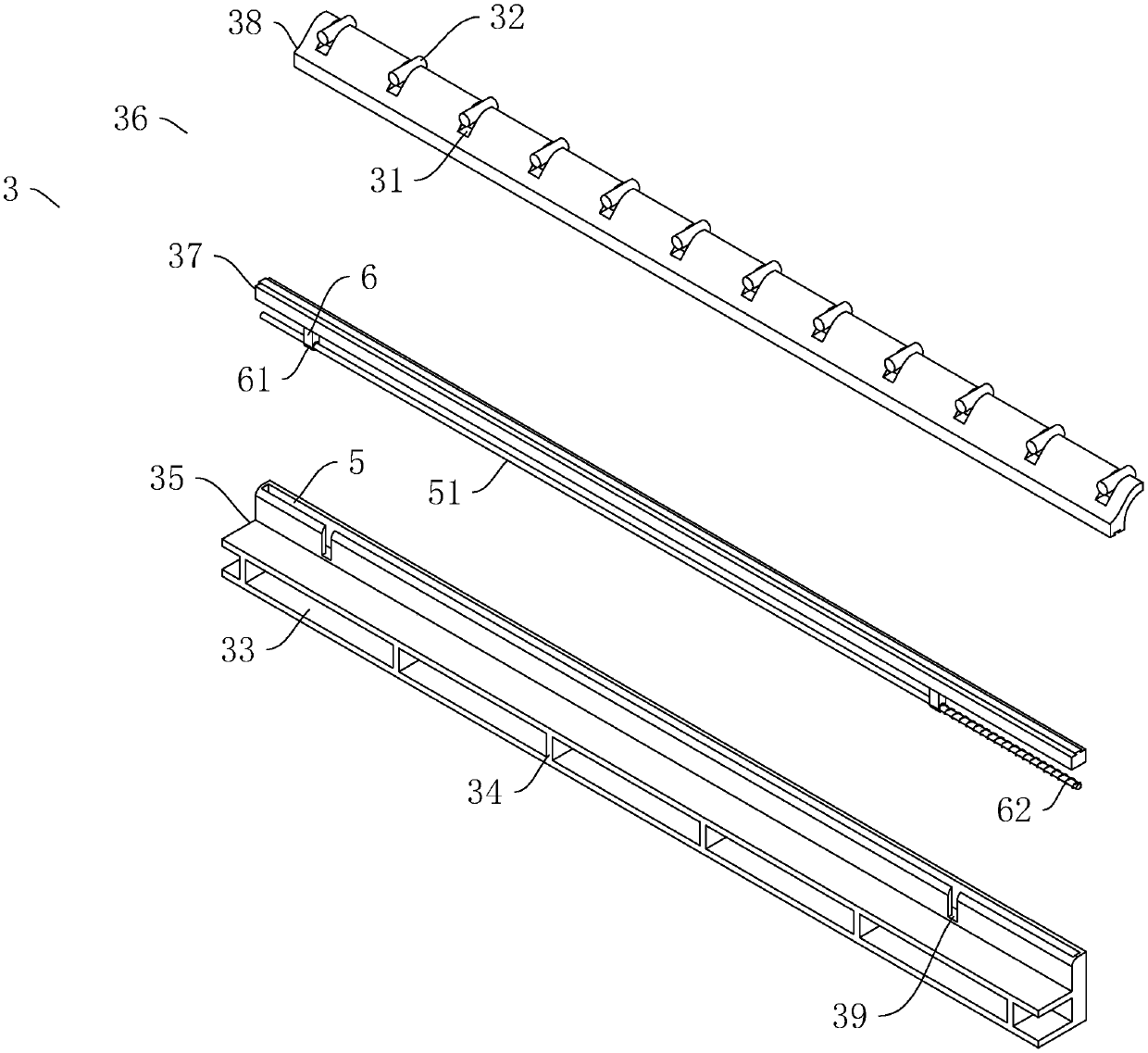

[0037] Such as figure 1 As shown, the upper end surface of the side mold strip 3 is provided with a plurality of installation grooves 31, and the plurality of installation grooves 31 are evenly distributed along the length direction of the side mold strip 3, and the installation groove 31 is embedded with a sponge plug 32. The outer wall of the side mold strip 3 is penetrated with grooves 33 along the length direction of the side mold strip 3, and a number of reinforcing ribs 34 are evenly arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com