Brick pressing mold

A technology of mould and pressing brick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

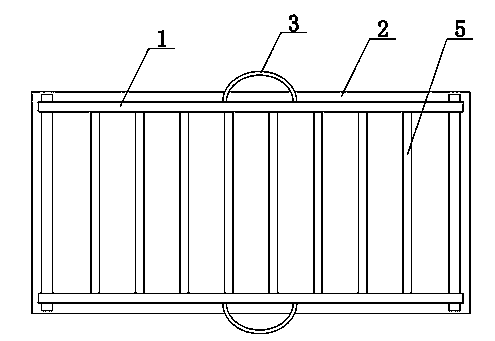

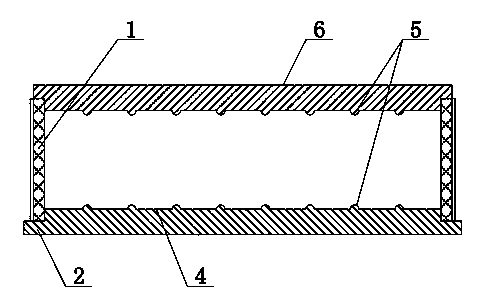

[0011] see figure 1 and figure 2 , the brick press mold of the present invention comprises a mold frame 1, a bottom plate 2 and a top plate 6, the mold frame 1 is arranged on the bottom plate 2, and the mold frame 1 is composed of four rectangular steel plates to form a cuboid frame, and the top plate 6 and the bottom plate 2 are located at The parts in the mold frame 1 are all higher than the surroundings to form a raised portion 4, and the surface of the raised portion 4 is provided with a convex strip 5, and the middle and upper part of the side of the mold frame 1 is provided with a suspension ring 3, and the cross section of the convex strip 5 is an arc shape.

[0012] During use, the material moves around under the action of the raised part 4 of the top plate 6 and the bottom plate 2, so that it is easier to be squeezed to the corners of the bricks, and the corners...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com