Method and device for manufacturing dovetail groove in back side of ceramic tile

A dovetail groove and dovetail technology, which is applied in the direction of manufacturing tools, molding surfaces, ceramic molding machines, etc., can solve the problems of tile panels falling off, life and property hazards, and tile plate detachment, etc., and achieve the effect of firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structure of the present invention will be described in detail below with reference to the drawings and embodiments:

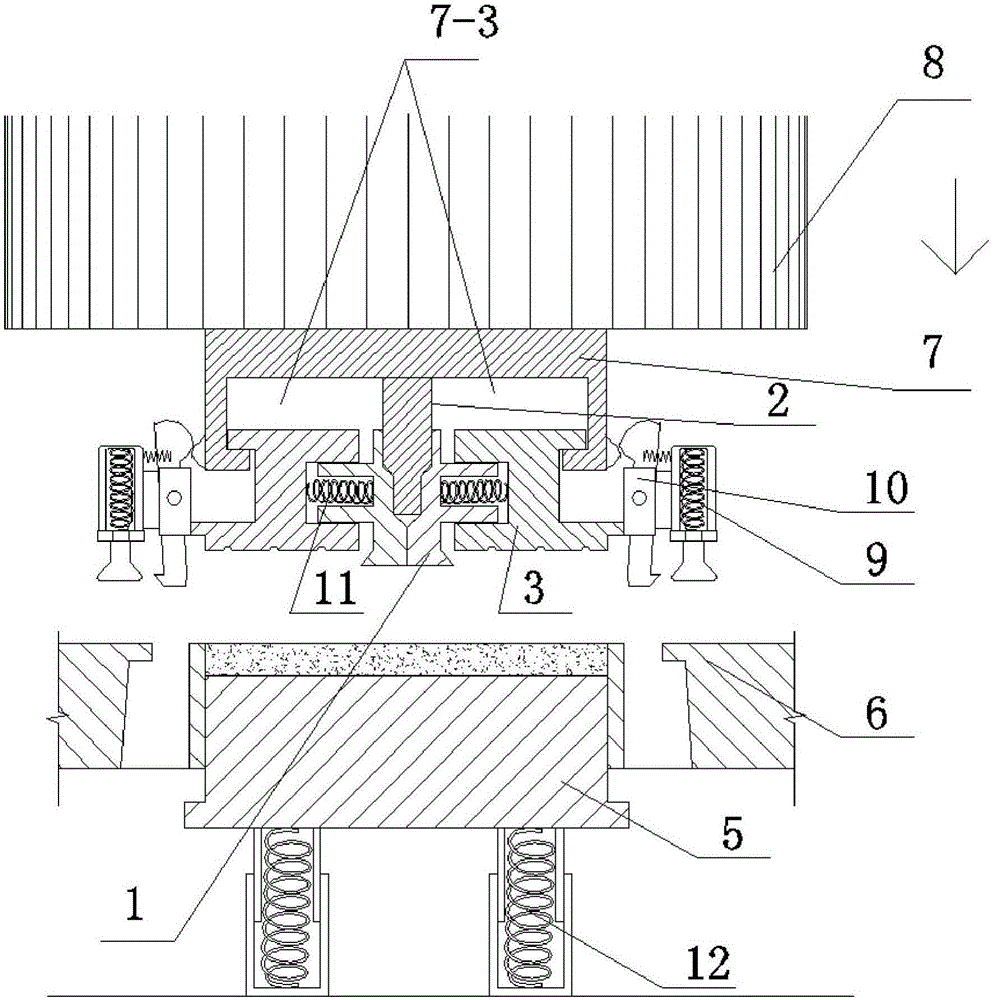

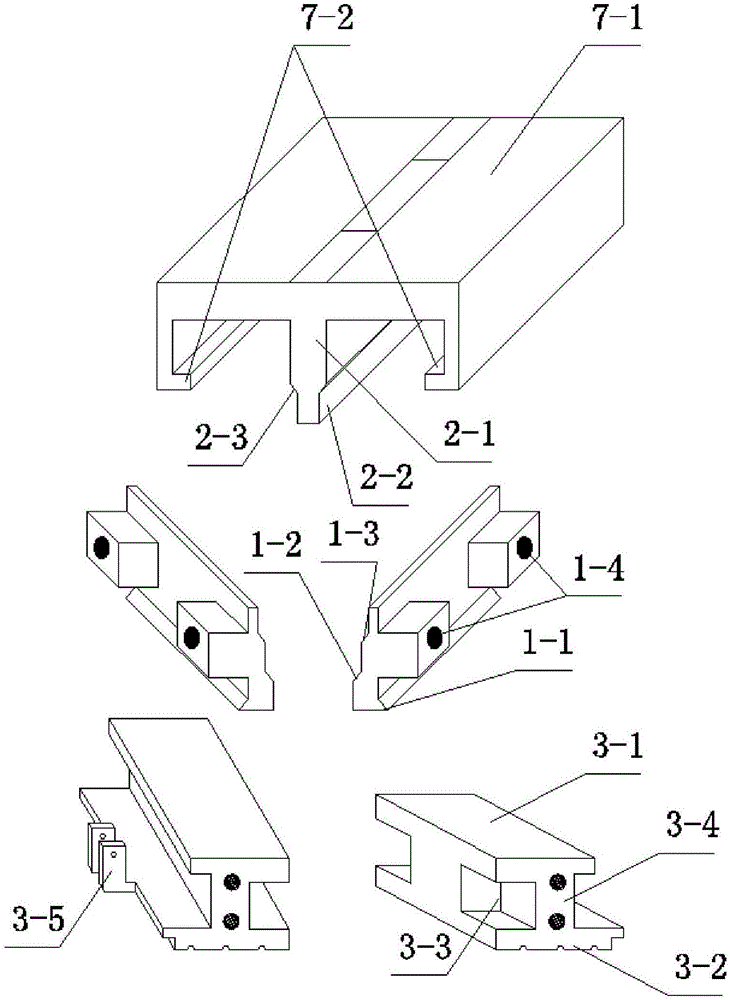

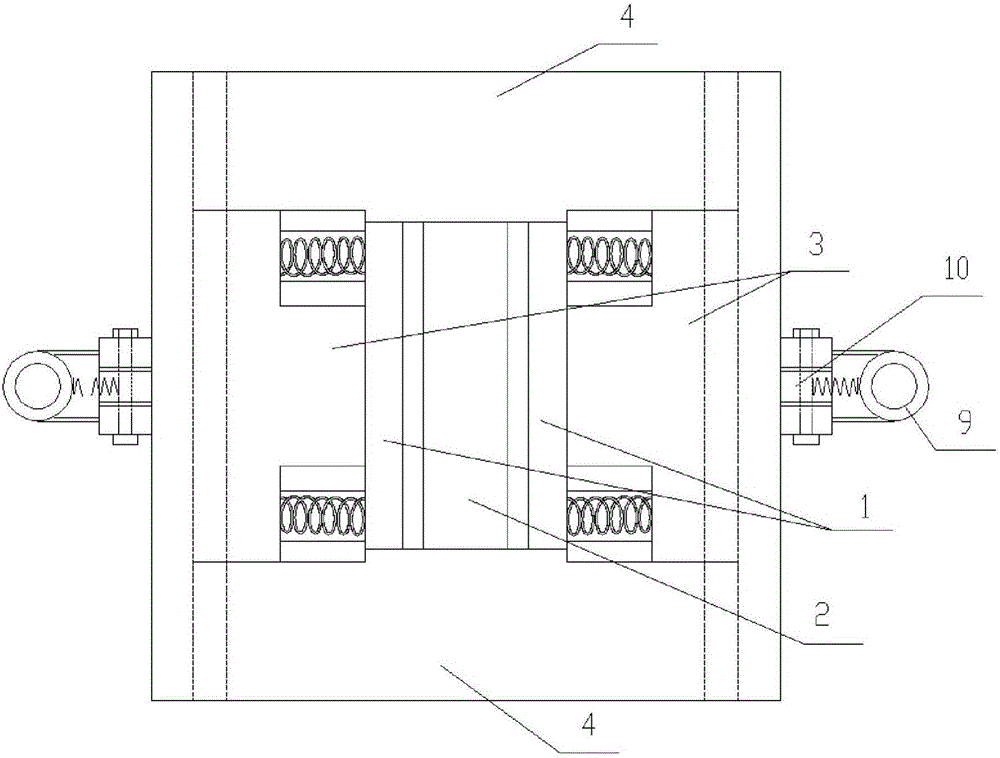

[0030] Such as figure 1 , Picture 1-1 with Figure 1-2 As shown in the present invention Equipment for making dovetail groove on the back of ceramic tile , Including pressure seat lift cover 7 , It is characterized in that: the pressure seat lift cover 7 includes a cover surface 7-1 and left and right side frames. A left frame and a right frame are respectively provided on both sides of the cover surface, and the bottom ends of the left frame and the right frame are provided There is an inwardly extending lifting arm 7-2, the cover surface and the left and right side frames jointly enclose an inner cavity, and a dovetail combined plug-in 2 is provided in the middle of the inner cavity, and the dovetail combined plug-in 2 includes a lower plug 2 -2, the dovetail assembly insert 2 divides the inner cavity into two left and right cavities 7-3, each cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com