Concrete civil air defense door and production process thereof

A production process and concrete technology, applied in the field of concrete air defense doors and their production processes, can solve the problems of increasing the weight of the air defense door leaf, high cost of the steel plate door leaf, inconvenient opening and closing of the air defense door, etc. and off the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

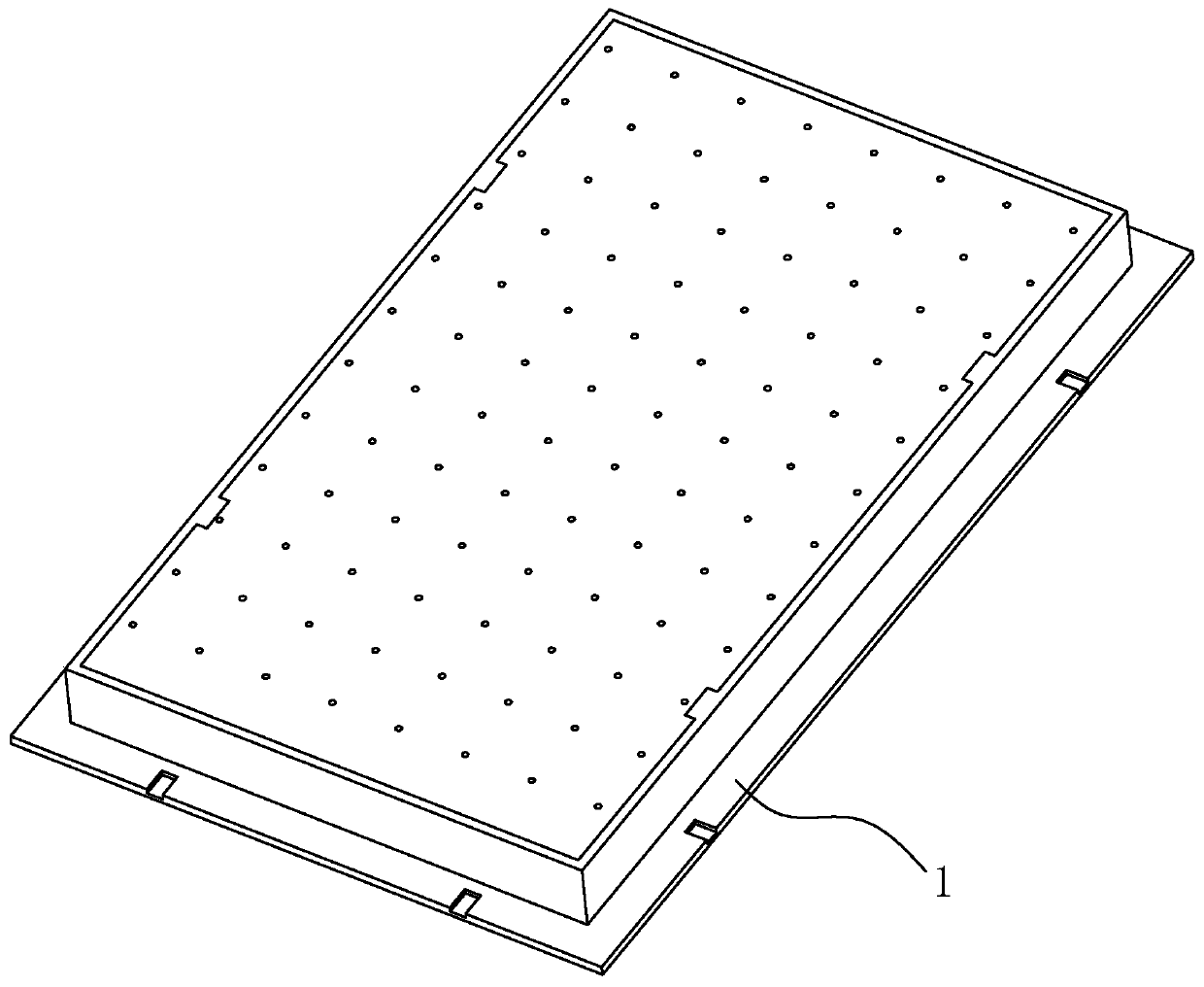

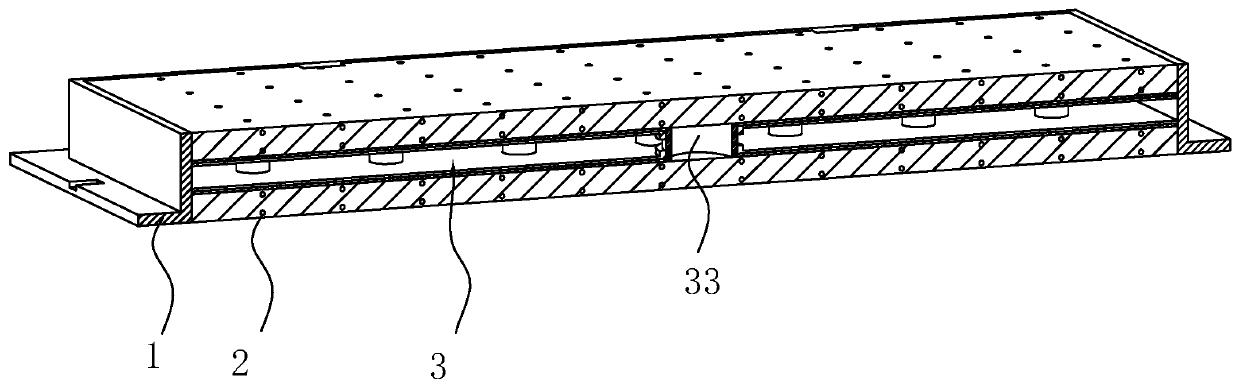

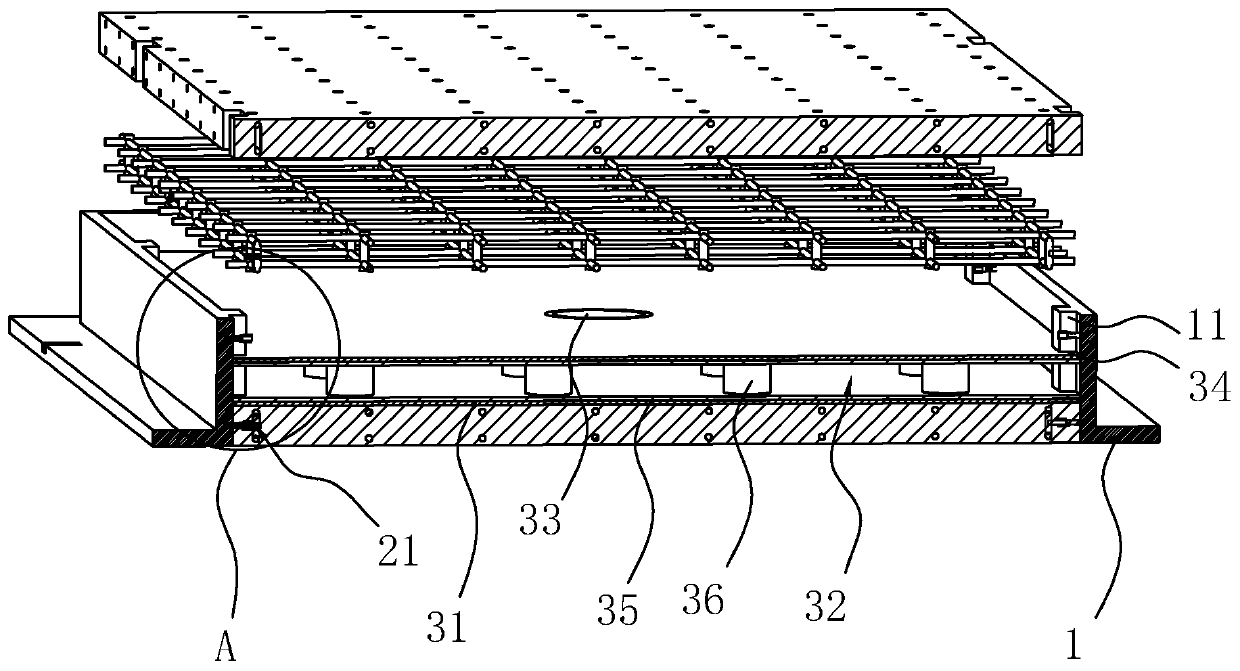

[0042] A concrete air defense door, see figure 1 with figure 2 , including a door frame 1, two steel frames 2 with the same structure are placed in sequence in the door frame 1, and a sandwich mechanism 3 for separating the two steel frames 2 is placed between the door frame 1, and the door frame 1 is located between the two steel frames 2 Concrete is poured into the position of the reinforcement frame 2, which can form a civil air defense door.

[0043] see figure 2 with image 3The interlayer mechanism 3 includes two steel plates 31, a cavity 32 is formed between the two steel plates 31, the two sides of the steel plates 31 are used to abut against the reinforcement frame 2, and the middle part of the two steel plates 31 is jointly fixed with a lower barrel 33 , the lower barrel 33 is used to communicate between the two steel skeletons 2, the two sides of the door frame 1 are symmetrically fixed with a guide plate 11, and the position of the steel plate 31 corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com