Prestressed concrete rail board die manufactured through bidirectional pre-tensioning method

A track plate and prestressing technology, which is applied in the direction of molds, mold auxiliary parts, manufacturing tools, etc., can solve the problems of occupying a lot of space, large material flow, and low efficiency of fixed model production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

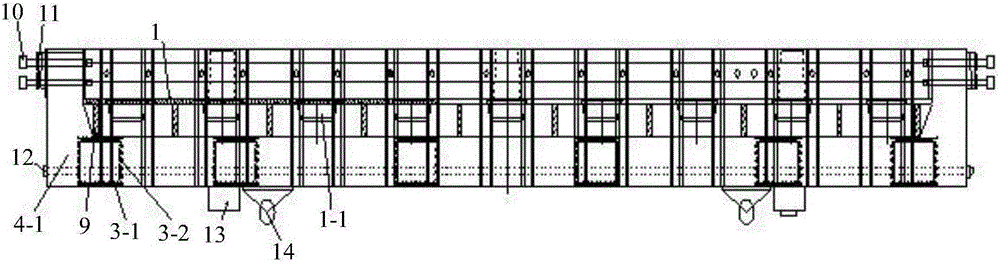

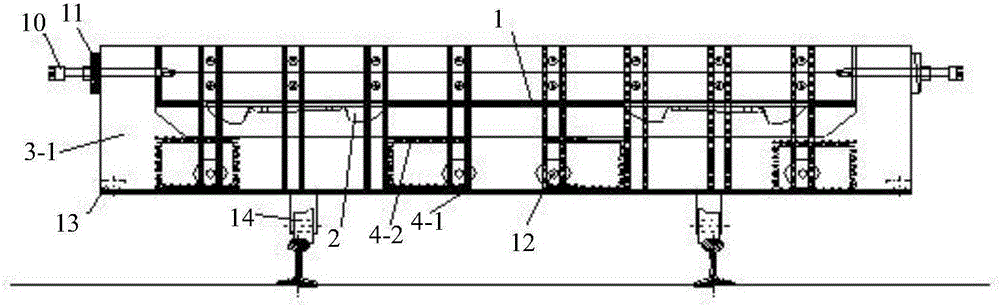

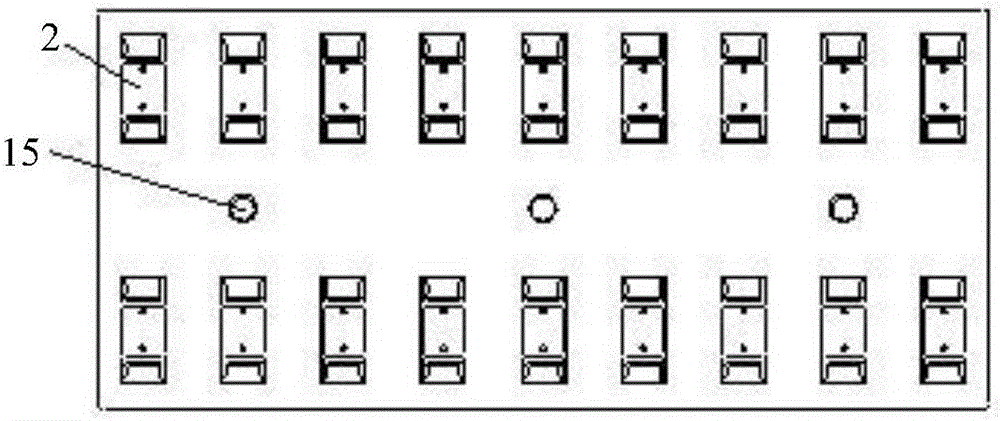

[0026] Such as Figure 1 to Figure 9 As shown, a two-way pretensioned prestressed concrete track slab mold includes: track slab bottom mold 1, rail bearing platform 2, load-bearing side mold 3, load-bearing end mold 4, tension plate 5, pressure plate 6, Prestressed steel bar hole 7, lifting sleeve hole 8, track plate bottom mold support steel plate 9, tension connecting rod 10, tension locking wedge 11, pretensioning balance force bar 12, model positioning hole 13, sliding wheel 14 and Perfusion hole mold 15.

[0027] There are 18 rail bearing grooves 1-1 evenly distributed on the bottom mold 1 of the track slab, arranged in parallel in pairs and arranged in two rows.

[0028] The 18 rail-supporting platforms 2 are firstly cast and then precision-machined, and are evenly distributed and embedded in the rail-supporting grooves 1-1. The rail support platform 2 has: a pre-embedded casing positioning pin 2-1.

[0029] There are two groups of embedded casing positioning pins 2-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com