Construction method optimizing deep foundation pit changing supporting construction sequences

A technology of construction sequence and construction method, which is applied in basic structure engineering, excavation, construction, etc., can solve the problem of long time for strength, small space for the edge of the base plate and supporting structure, and difficulty in cleaning debris and backfilling rammed soil construction operations, etc. problems, to achieve the effect of shortening the construction period and reducing the risk of the foundation pit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

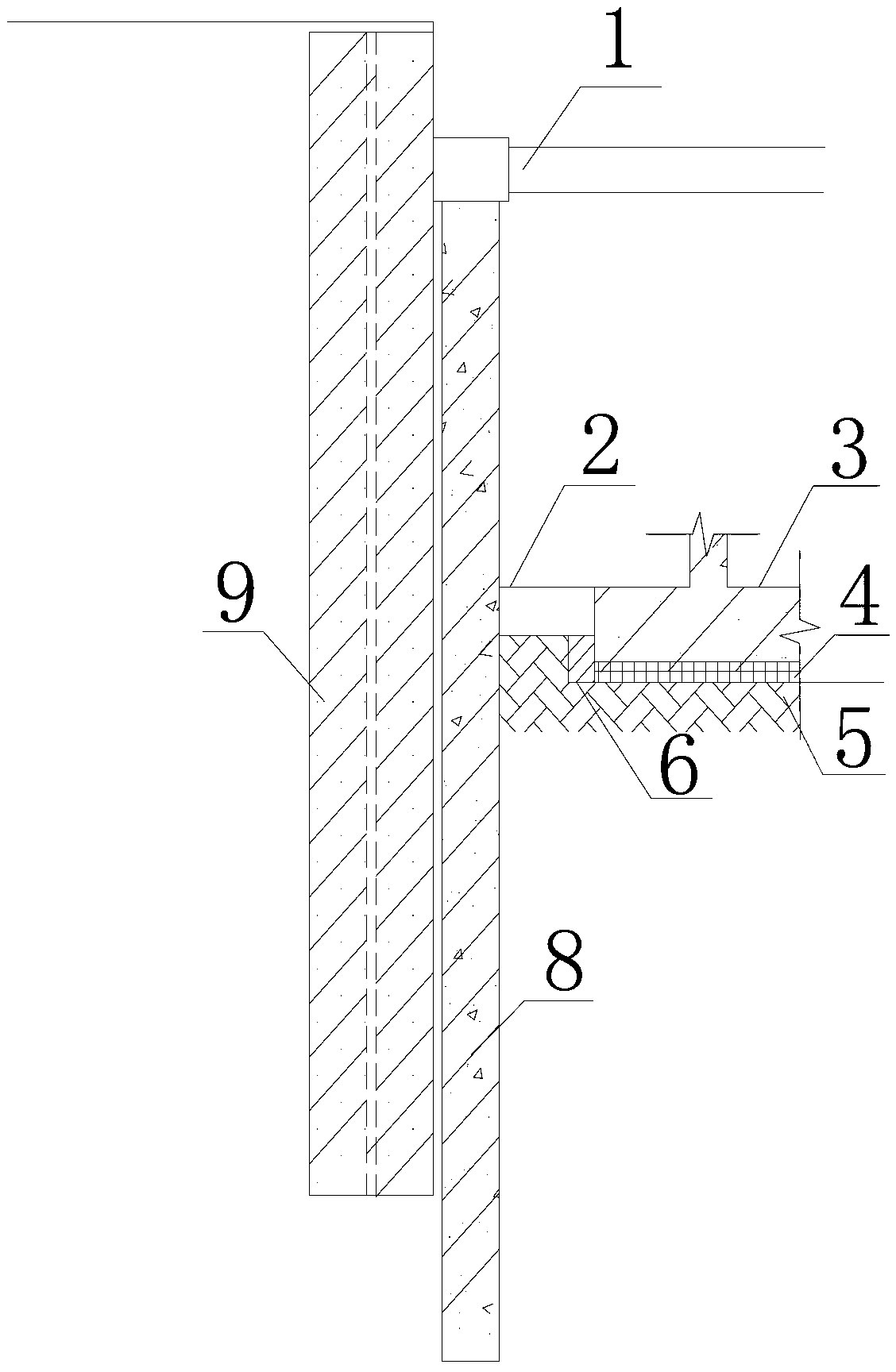

[0022] see figure 1 , a construction method for optimizing the construction sequence of deep foundation pit replacement. It adopts the reverse method for sequential construction. The support structure system of the foundation pit is composed of bored grouting support piles 8 and water-stop curtains 9. Leave the original soil layer 5 below the brace structure 2, after the foundation pit grooves and the foundation brick formwork 6 are built, pour the brace structure 2 and the cushion layer 4 at the same time, and use the brace structure 2 and the foundation brick formwork 6 as the bottom plate at the same time For the outer formwork, pour the base plate 3 after the waterproof construction is completed, and the upper horizontal support structure 1 can be dismantled when the strength of the concrete of the support structure 2 and the base plate 3 reaches the strength that the horizontal support structure 1 can be removed.

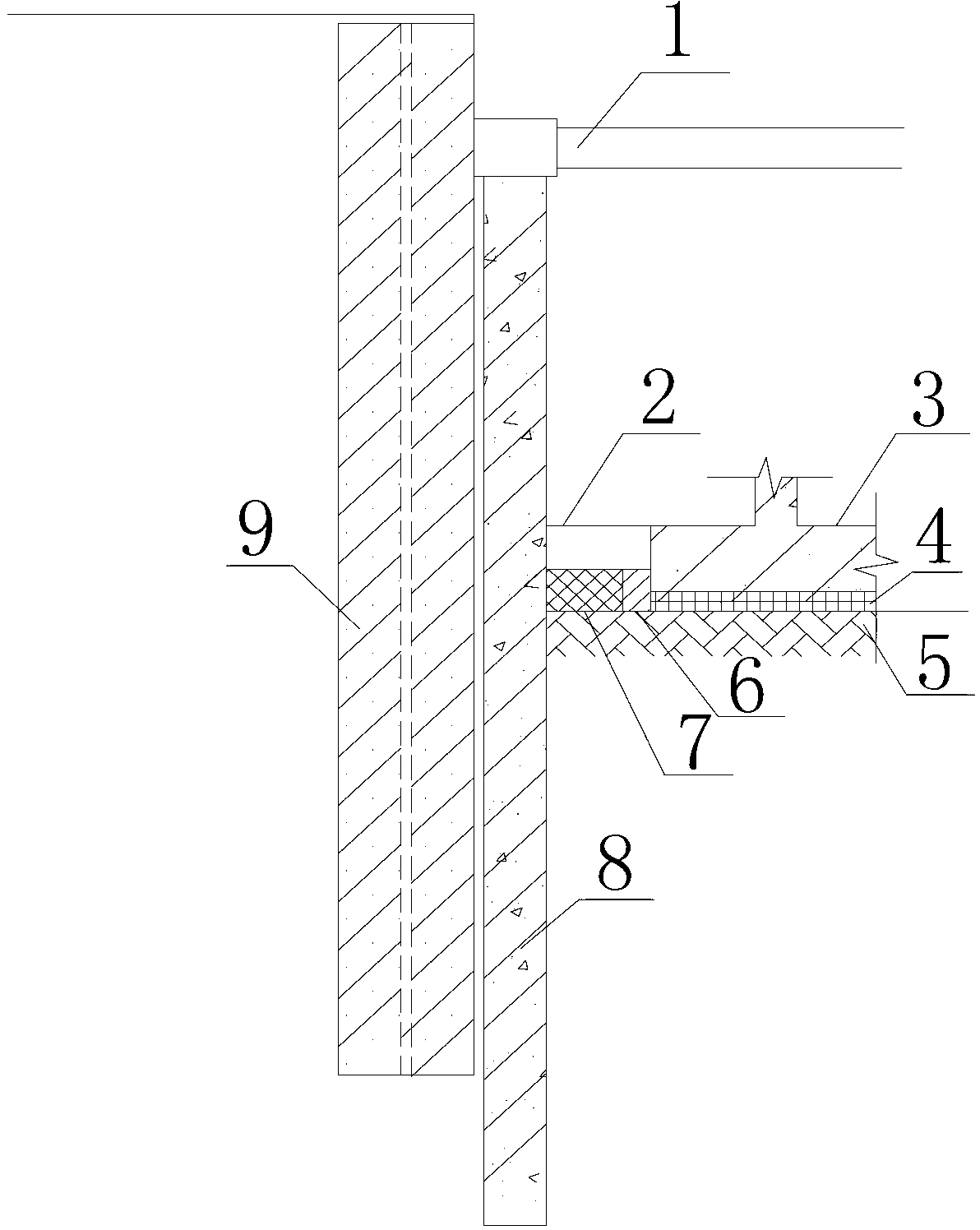

[0023] In the present invention, as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com