Long pile and short pile combined single-row pile and horizontal internal support pile supporting structure and construction method thereof

A technology of support structure and long and short piles, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of increasing foundation pit support cost and wasting resources, and achieve the effect of saving construction period, reducing waste of resources and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

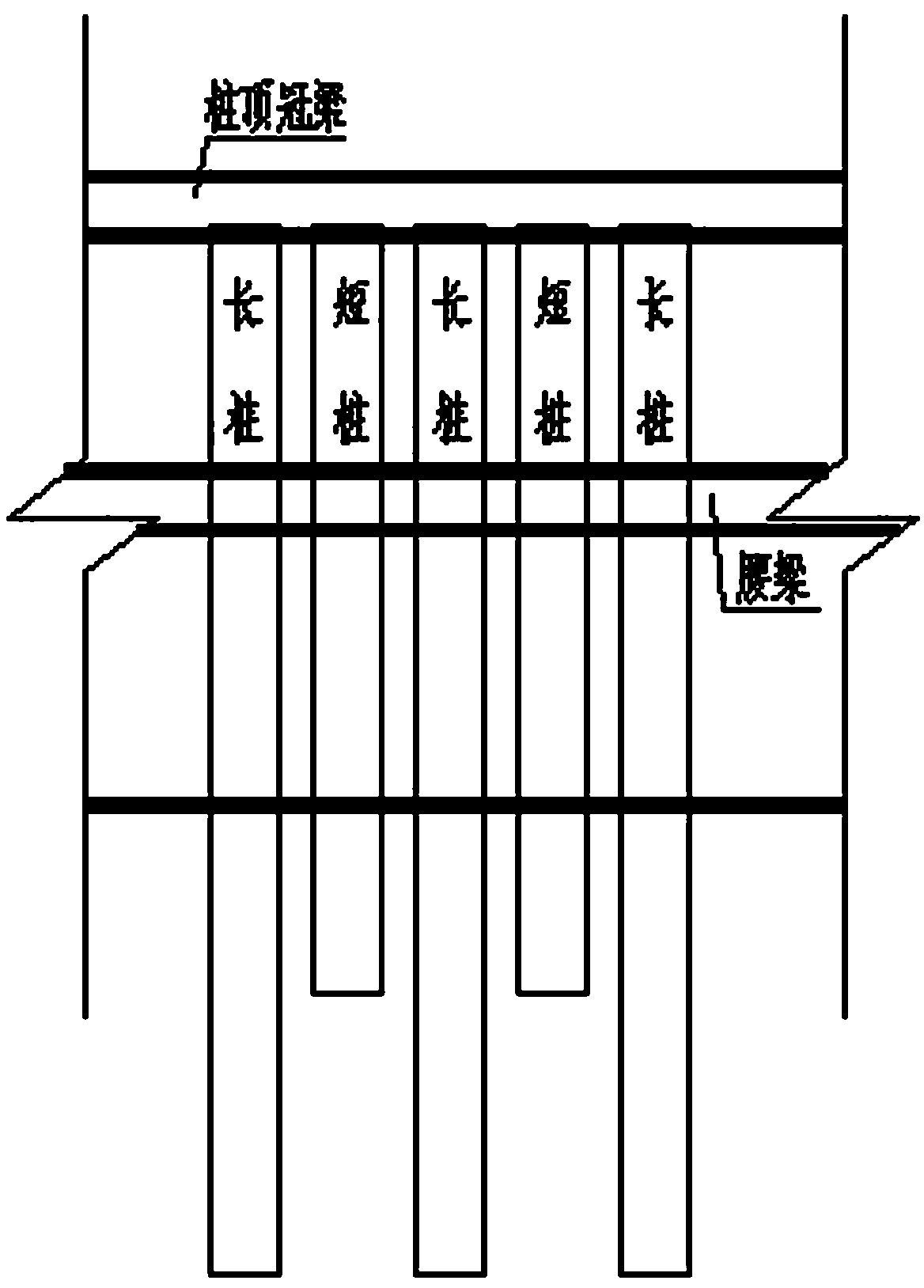

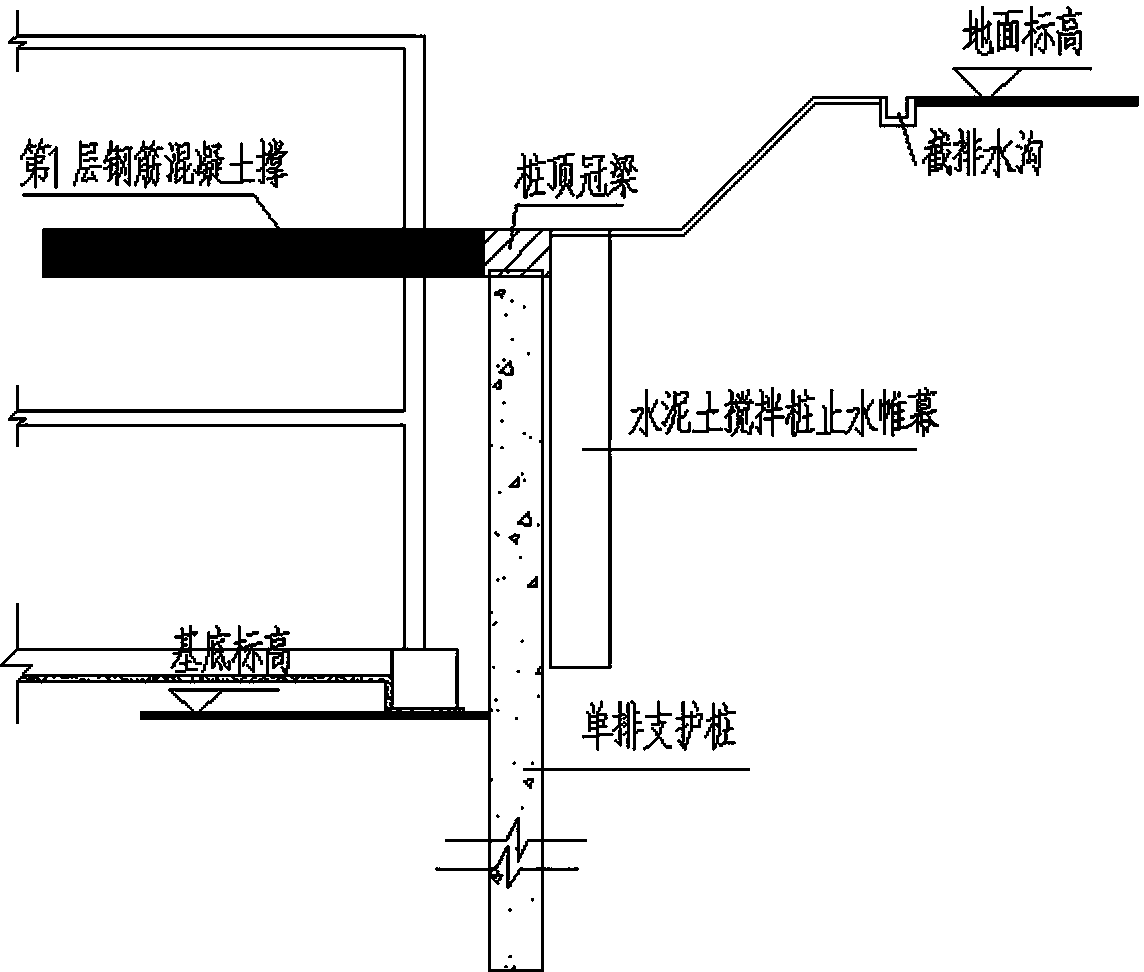

[0031] according to figure 1 , figure 2 , Figure 5 Shown, a kind of construction method of the pile support structure of the single-row pile+2-layer horizontal steel pipe brace that a kind of long and short pile combines, its steps are as follows:

[0032] ①Long pile construction: measuring and setting out, drilling rig in place, hole formation, hole cleaning, steel cage installation, conduit installation, secondary hole cleaning, underwater concrete pouring;

[0033] ②Short pile construction: measurement and setting out, drilling rig in place, hole formation, hole cleaning, steel cage installation, conduit installation, secondary hole cleaning, underwater concrete pouring;

[0034] ③ Curtain construction of cement-soil deep mixing piles: deep mixer positioning, cement slurry preparation, pre-mixing and sinking, spraying and mixing, lifting, repeated mixing and sinking, repeated mixing and spraying to lift to the orifice, shutdown, cleaning, and displacement;

[0035] ④ B...

Embodiment 2

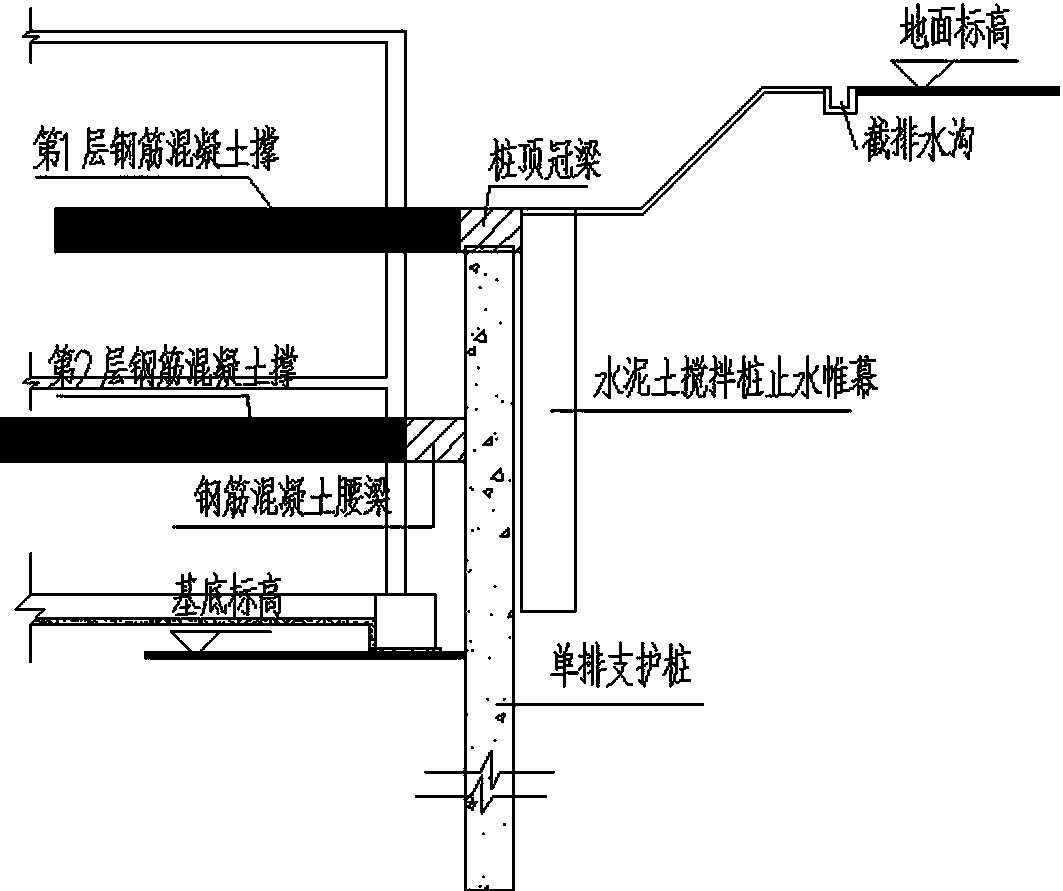

[0042] according to image 3 , Figure 4 , Figure 5 Shown, a kind of construction method of the pile support structure of single row pile+1 layer of horizontal reinforced concrete support that combines long and short piles, its steps are as follows:

[0043] ①Long pile construction: measuring and setting out, drilling rig in place, hole formation, hole cleaning, steel cage installation, conduit installation, secondary hole cleaning, underwater concrete pouring;

[0044] ②Short pile construction: measurement and setting out, drilling rig in place, hole formation, hole cleaning, steel cage installation, conduit installation, secondary hole cleaning, underwater concrete pouring;

[0045] ③ Curtain construction of cement-soil deep mixing piles: deep mixer positioning, cement slurry preparation, pre-mixing and sinking, spraying and mixing, lifting, repeated mixing and sinking, repeated mixing and spraying to lift to the orifice, shutdown, cleaning, and displacement;

[0046] ④ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com