Annular steel structure supporting construction method with open type TBM (tunnel boring machine)

A construction method and an open technology, which is applied in the construction field with adverse geological conditions, can solve problems such as difficulty in passing brace shoes, difficulty in ensuring welding quality, and reduced bearing capacity of arch frames, so as to save construction investment, eliminate manual cleaning, and strengthen The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0043] general presentation

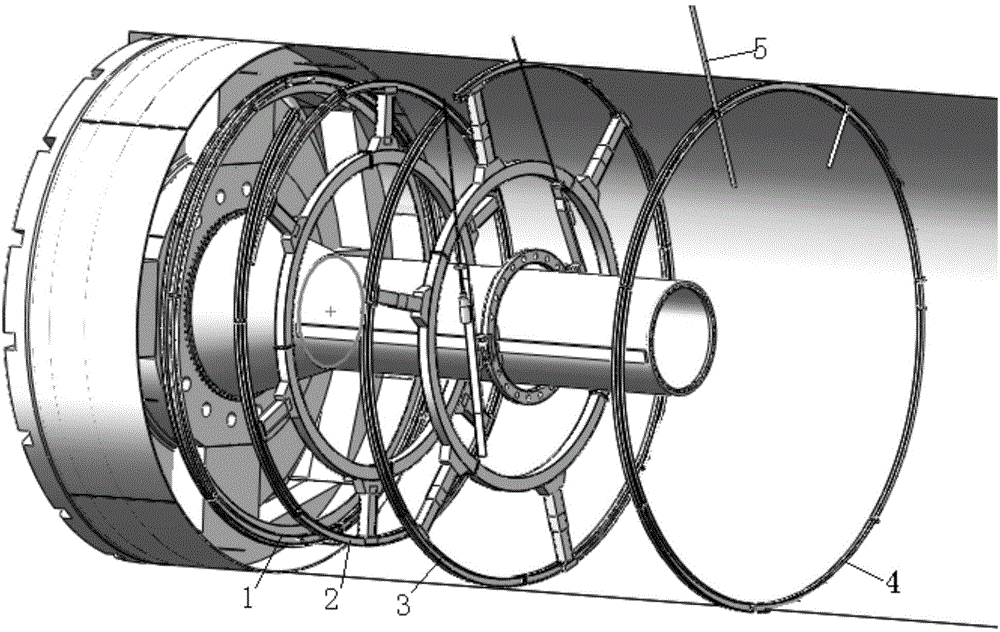

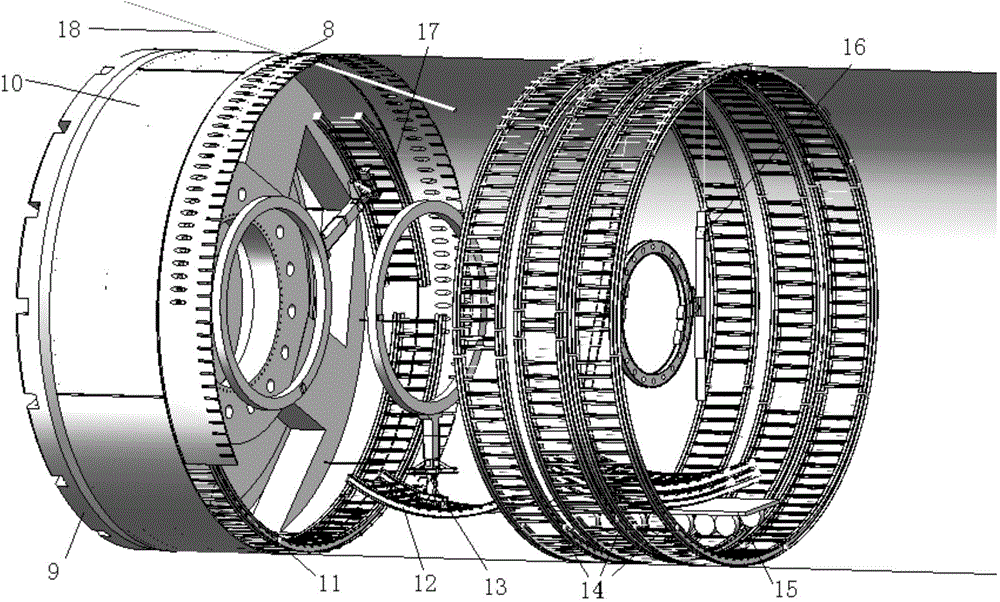

[0044] attached image 3 Taking the installation of the whole ring steel grid as an example, the mark 8 is the TBM shield that can accommodate the installation of the ring steel structure, 9 is the TBM cutter head, and 10 is the original short shield of the TBM; the mark 12 is the ring steel structure manipulator 13 The segment of the ring-shaped steel structure grabbed from the transport vehicle 15; the mark 17 is the segment of the ring-shaped steel structure being assembled by the manipulator; the mark 11 is the segment of the ring-shaped steel structure at the inverted arch that has just been assembled; the mark 14 is the completed installation Three continuous ring-shaped steel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com