Super early receiving supporting structure of shield machine and super early receiving method

A support structure and shield machine technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of low efficiency of shield machine use, long construction period, and the inability of shield machine to receive in advance, so as to avoid the unexpected The effects of leaving hoisting openings, scientific construction procedures, and convenient construction organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

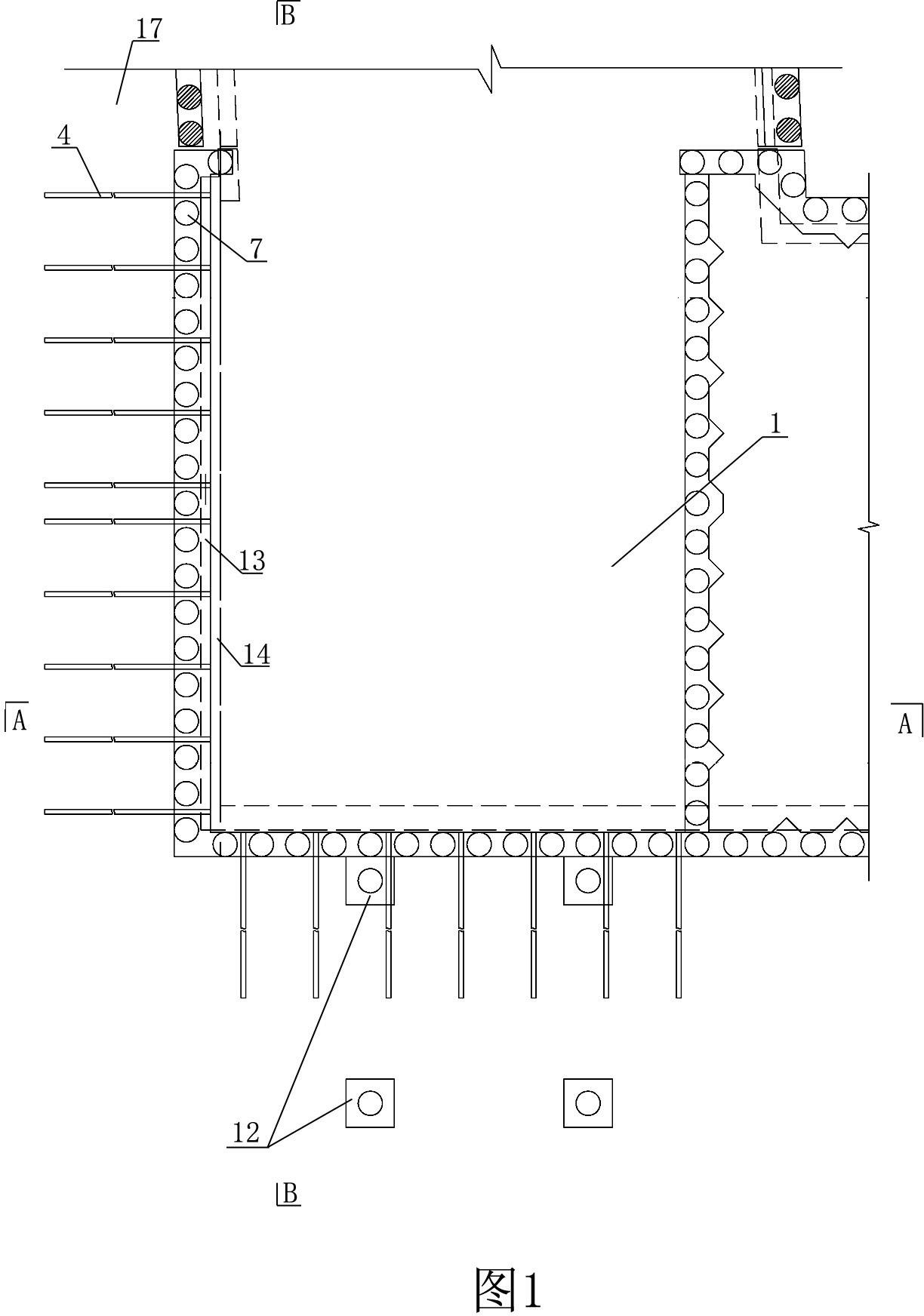

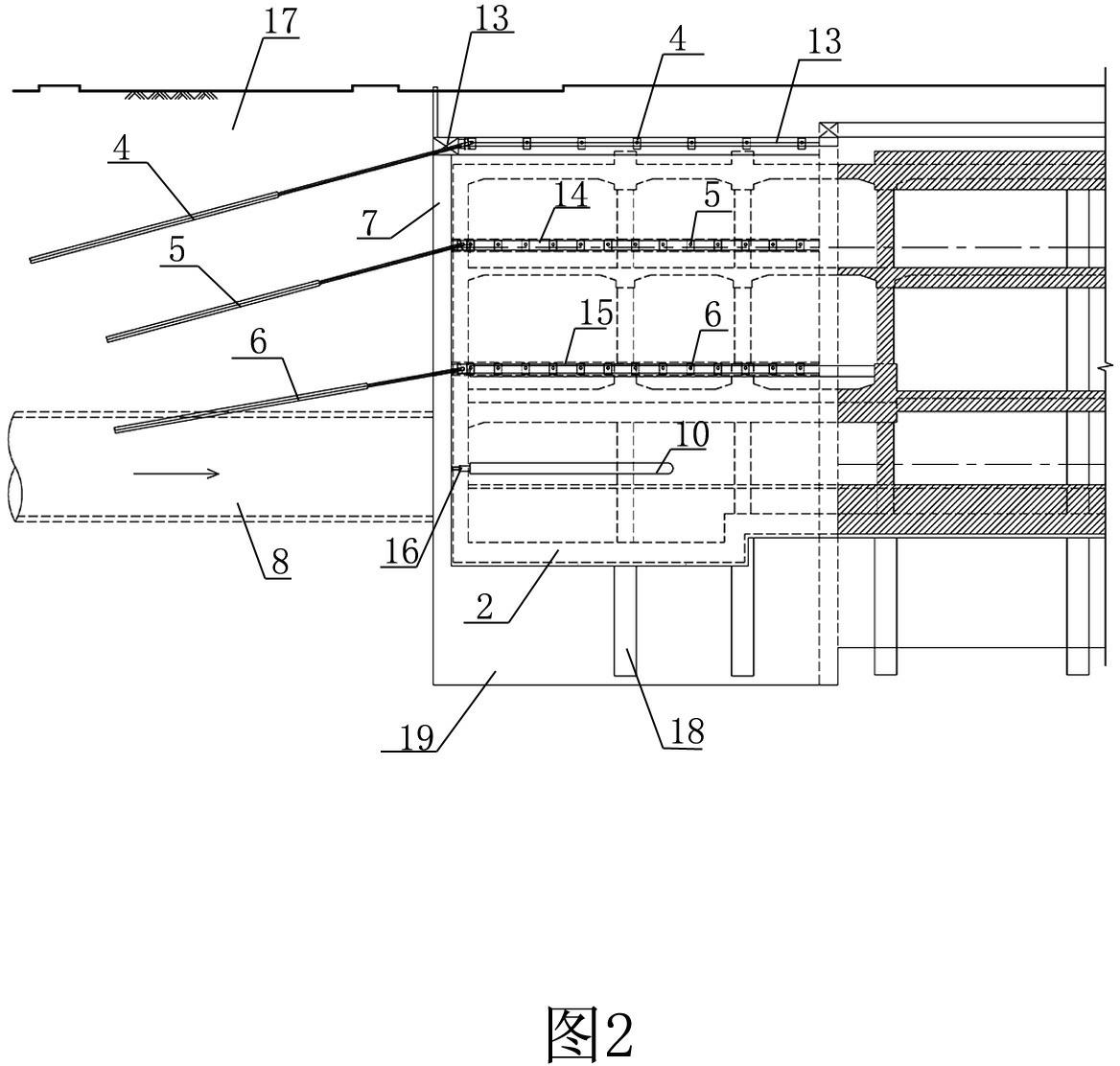

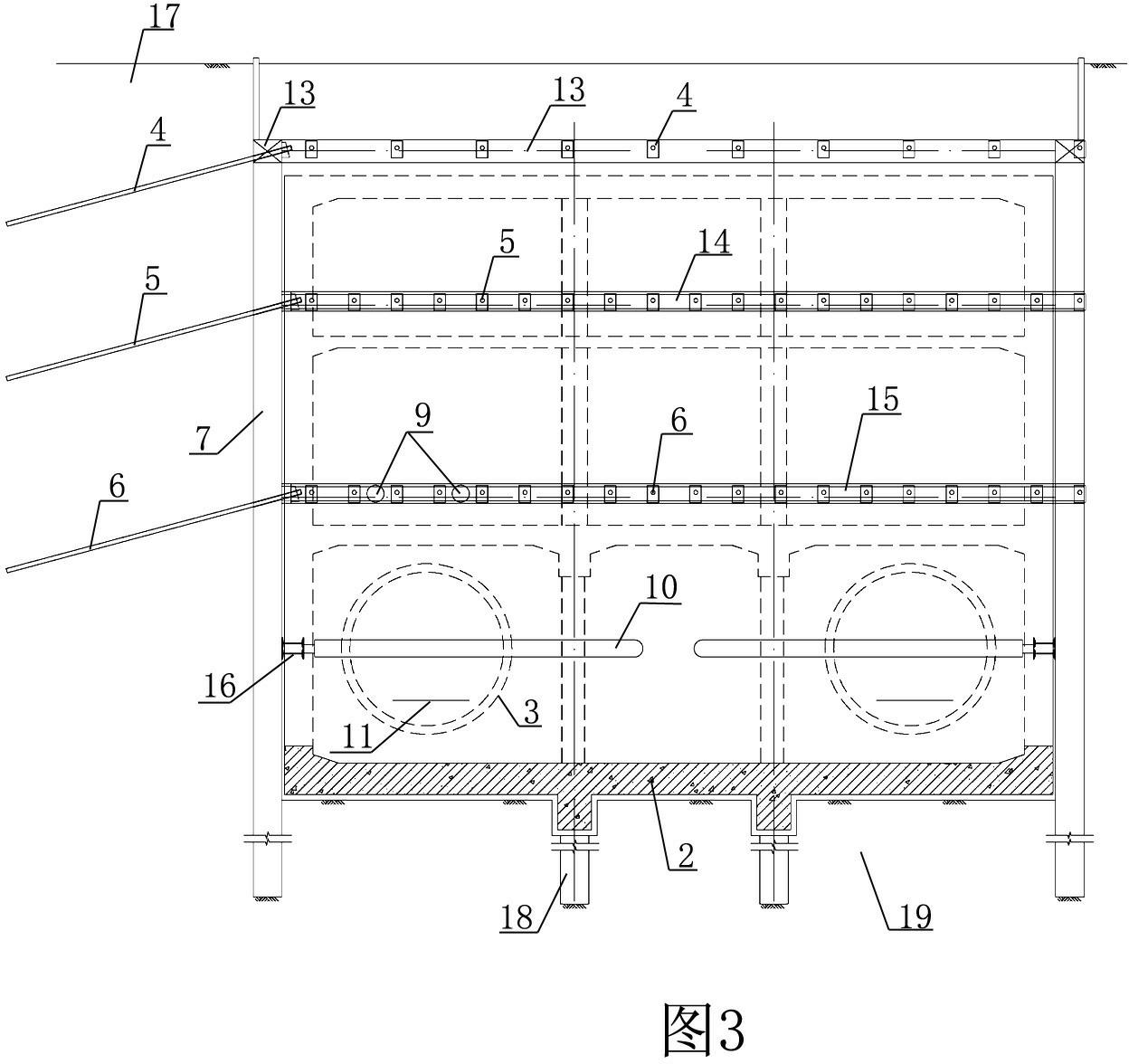

[0041] Examples see Figure 1 ~ Figure 3 As shown, an ultra-early receiving support structure for a shield machine is characterized in that it includes receiving pit foundation pit wall support, floor support and exit support.

[0042] The foundation pit wall support of the receiving well includes foundation pit surrounding protection piles 7 arranged around the inner wall of the foundation pit, at least two anchor cables and steel pipe angle supports 10 arranged at the angle between adjacent surfaces of the foundation pit wall, and the anchor cables Extending obliquely into the soil 17 around the foundation pit, the top surface of the foundation pit surrounding protection pile 7 is provided with a ring of crown beams 13, the first anchor cable is anchored to the crown beam, and the foundation pit surrounding protection piles 7 are spaced apart. A waist beam is provided, and the two ends of the steel pipe angle support 10 are connected to the last waist beam 16, and the remain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com