Weak surrounding rock large section tunnel double-side-wall pilot tunnel support structure excavated through three-step method and construction method

A technology of double-sided guide pit and weak surrounding rock, applied in tunnels, tunnel linings, earth-moving drilling and mining, etc., can solve the problems of high construction risk and difficult to guarantee the quality of lining in the later stage, saving engineering materials, reducing the number of demolition, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

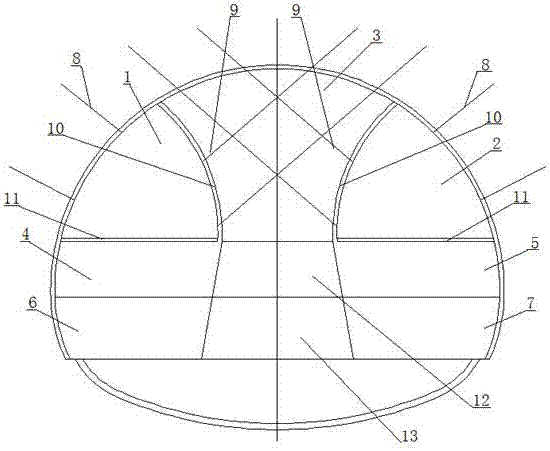

[0015] see figure 1 , a three-step excavation and support structure for double-side pilot pits and large-section tunnels with soft surrounding rocks, which is suitable for rapid construction of large sections with weak surrounding rocks, including upper support, middle support and lower support from top to bottom .

[0016] see figure 1 , the upper support includes the left side wall pilot pit support 1, the middle partition wall support 3 and the right side wall pilot pit support 2, and the middle support includes the left middle step support 4 and the right middle step Support 5, the lower support includes left lower step support 6 and right lower step support 7. The guide pit support 1 on the left side wall and the pilot pit support 2 on the right side wall respectively include a steel arch I and a temporary support, and the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com