Extremely-high geostress soft rock large-deformation tunnel multistage pressure-yielding and pressure-resisting support structure and construction method thereof

A technology of supporting structure and in-situ stress, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of slow construction progress and increased project costs, and achieve the goal of ensuring construction progress, good stress state, and controlling project investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in combination with specific embodiments.

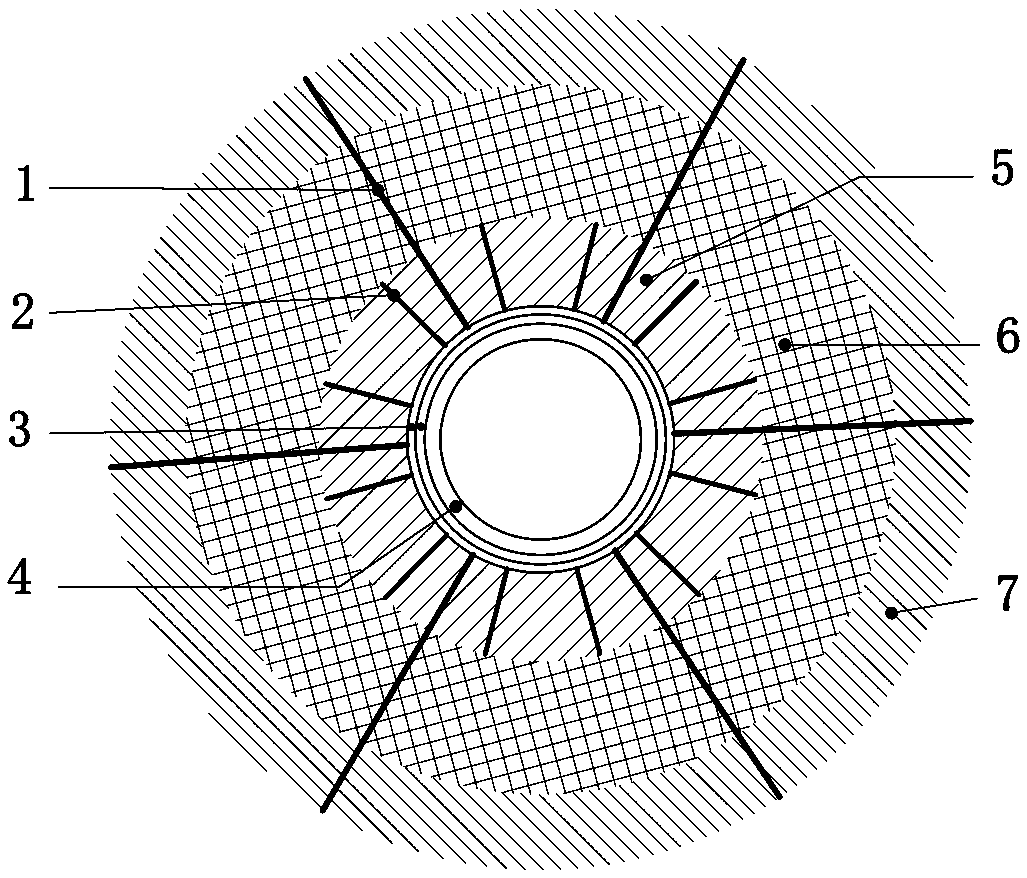

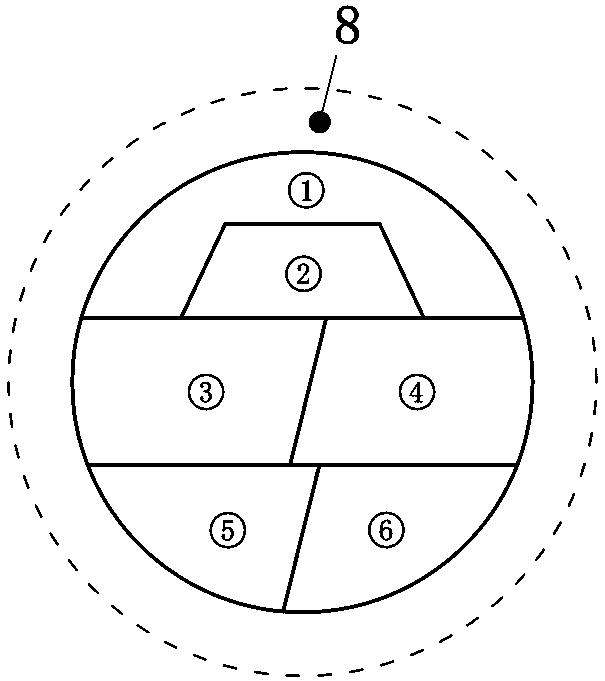

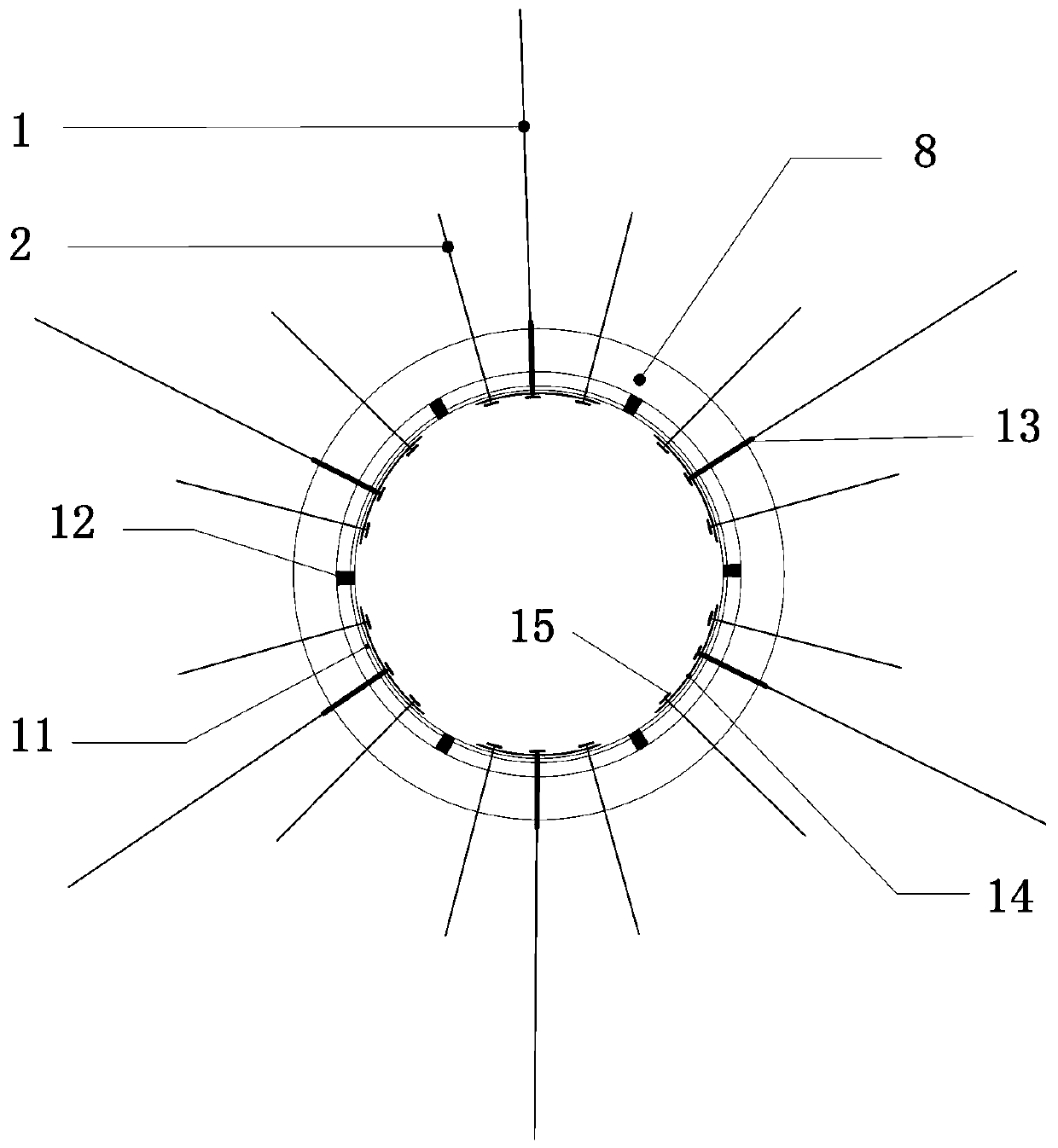

[0043] The invention relates to a multi-stage yielding support structure for a tunnel with extremely high ground stress and large deformation in soft rock that can realize active control. After excavating a tunnel with a near-circular cross-section, long anchor cables 1 and short anchor rods are laid at intervals in the surrounding rock 2. Set up a ring-shaped steel frame at the end of the long anchor cable 1 and the short anchor rod 2 and spray concrete. After a certain period of time, add reinforcement and lengthen or encrypt the anchor cable 10 to the surrounding rock, spray concrete again, and erect the steel frame. multi-layer deferred support 3; the inside of multi-layer deferred support 3 is made of reinforced concrete lining structure 4, long anchor cable 1, short anchor rod 2, multi-layer deferred support 3 and reinforced concrete lining structure 4 form a multi-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com