Rail mounting apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

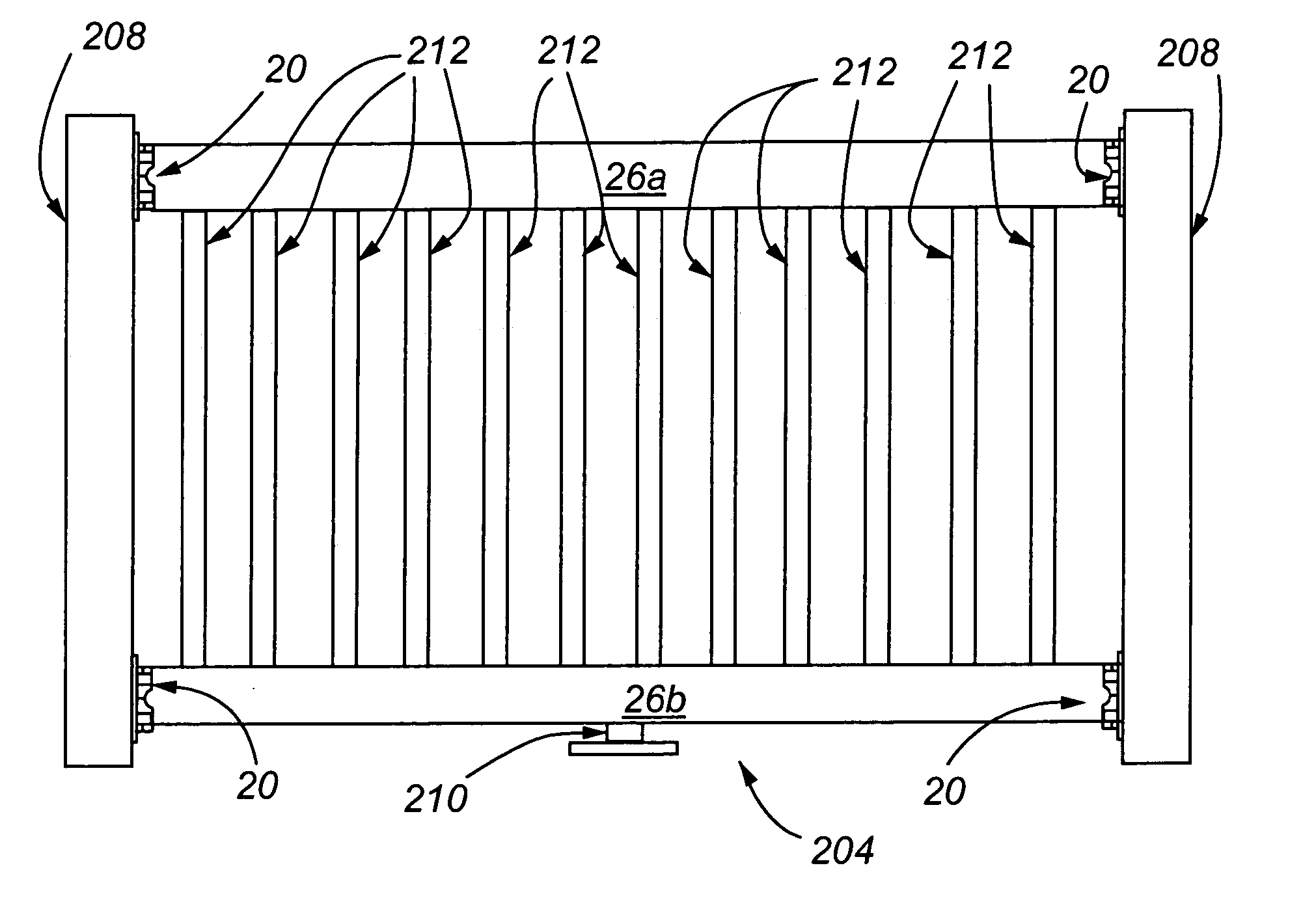

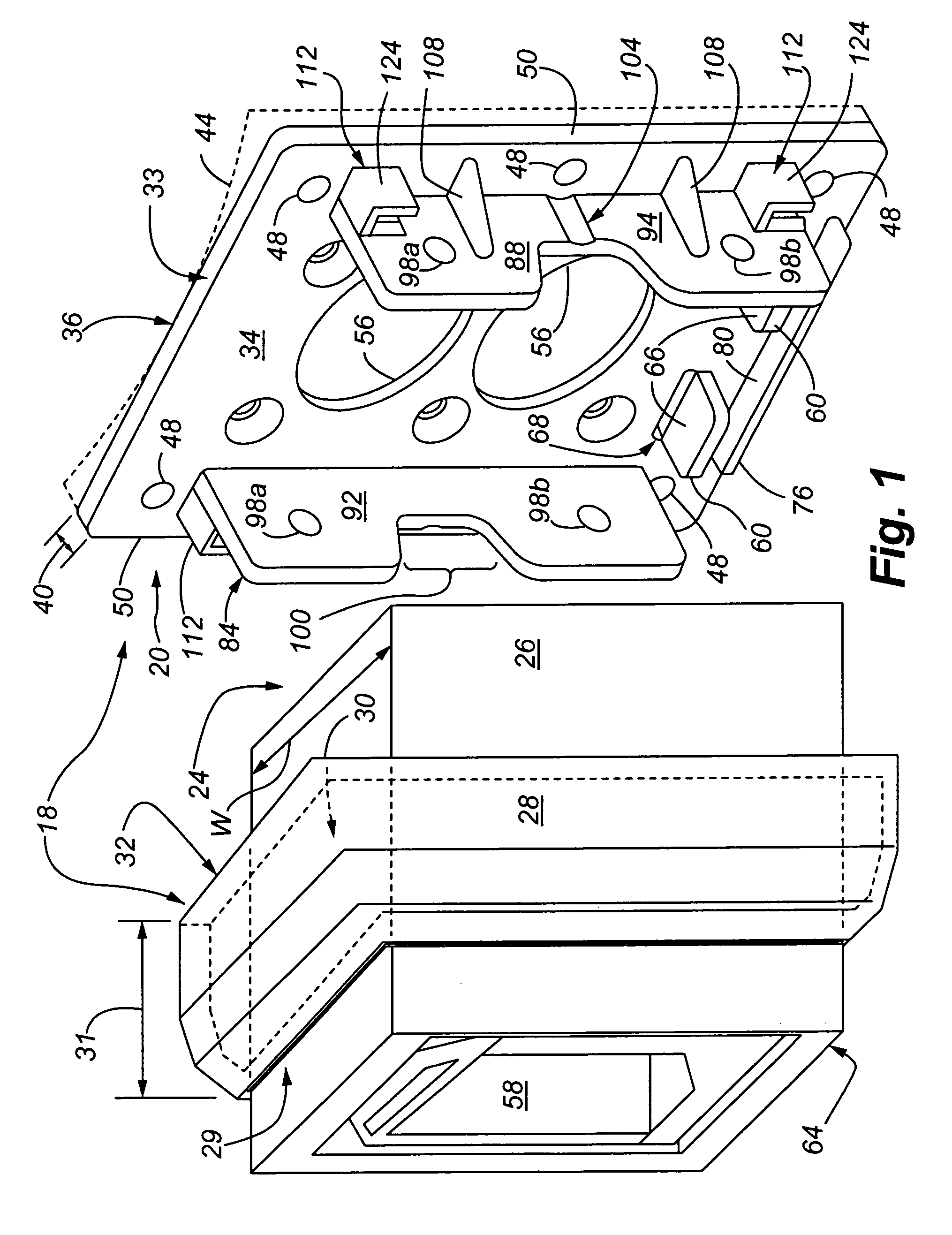

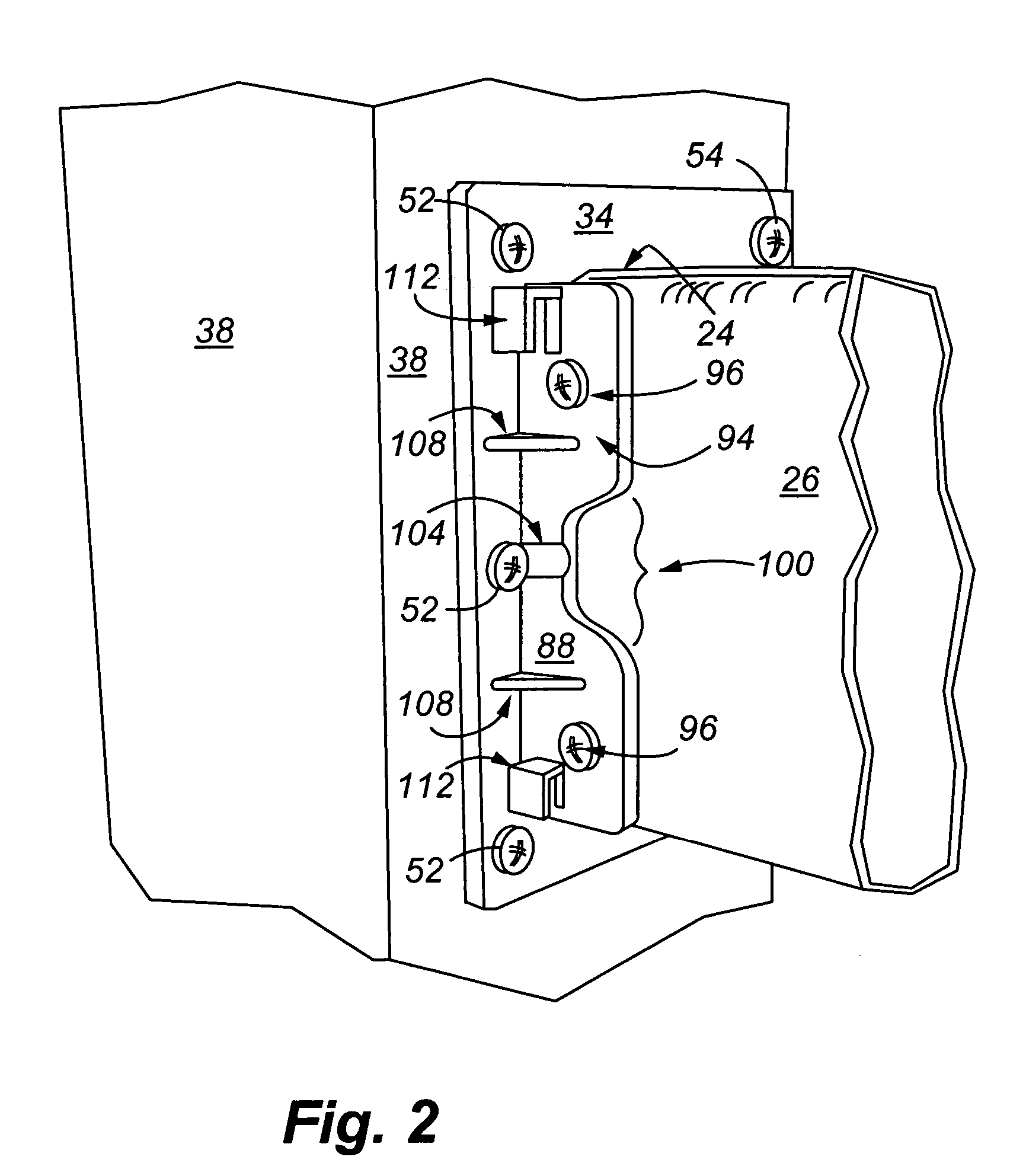

[0035]FIG. 1 shows an embodiment of the rail mounting system 18. The rail mounting system 18 includes a bracket 20 for mounting an end 24 of a rail 26 thereto (e.g., a synthetic rail, or alternatively, a wood, or metal rail). The rail 26 may be, e.g., up to ten feet in length (FIG. 1 does not show such a length of the rail 26 according to scale), and may have cross sectional dimensions of, e.g., less than eight inches by eight inches. The bracket 20 is correspondingly dimensioned to appropriately mate with the rail end 24. Additionally, the rail mounting system 18 includes a bracket cover 28 (e.g., FIGS. 1 and 8) for covering the bracket 20 once the rail end 24 is secured to the bracket 20 (as shown in FIG. 2). The bracket cover 28 may be manufactured from a moldable material(s) such as, e.g., vinyl, PVC, plastic, and the like. The bracket cover 28 includes a central channel 30 extending through the thickness 31 of the bracket cover, wherein a front end opening 29 of the central cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com