Boron-containing aluminosilicate glass capable of realizing rapid ion exchange

A boroaluminosilicate and ion exchange technology, which is applied in the field of strengthened glass preparation, can solve the problems of reduced damage resistance, reduced surface compressive stress of strengthened glass, and reduced ion exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

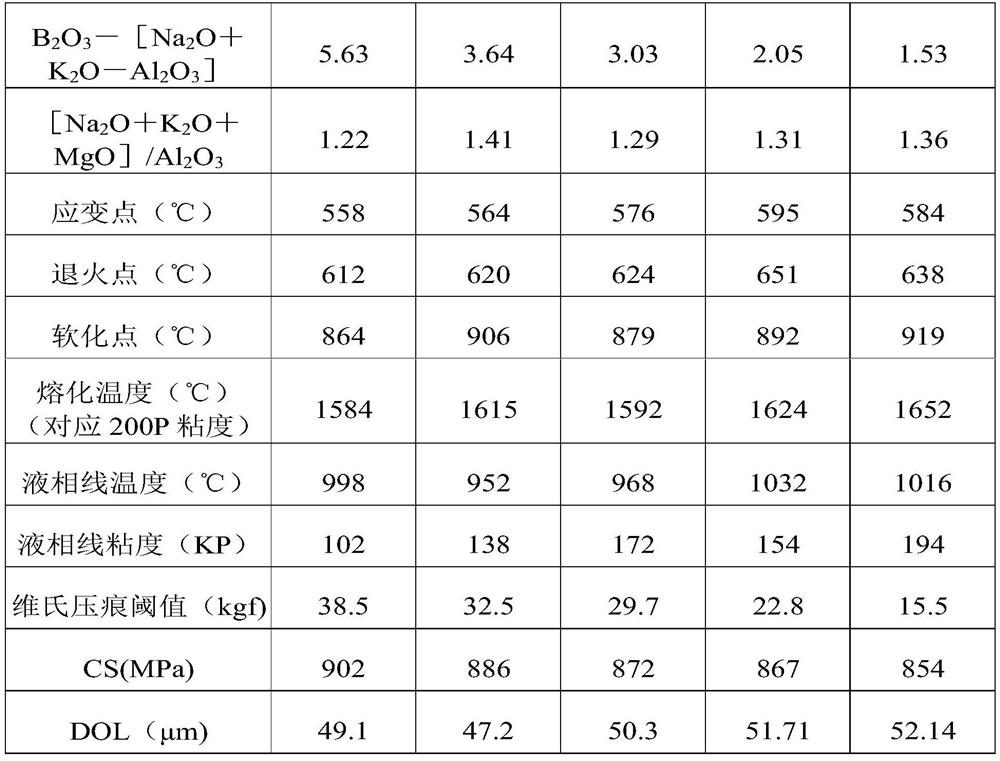

[0029] The present invention is a boron-containing aluminosilicate glass capable of rapid ion exchange and its surface ion exchange method. The aluminosilicate glass with high compressive stress is formed on the surface through ion exchange, which not only has high inherent damage resistance, but also It has high ion exchange kinetics and fast exchange capacity. After ion exchange chemical strengthening treatment, it can obtain deeper ion exchange depth and high surface compressive stress, so as to achieve higher mechanical strength, bending strength and impact damage resistance. performance.

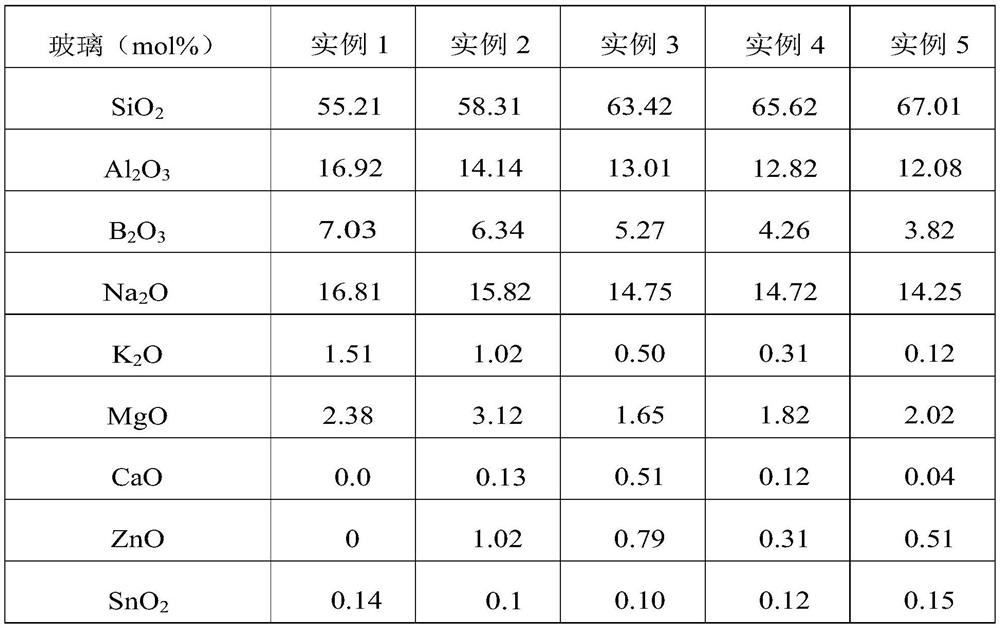

[0030] One aspect of the present invention provides a boron-containing aluminosilicate glass capable of rapid ion exchange, which comprises: 54-68 mol% SiO in terms of mole percent 2 , 12-20mol% Al 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com