Aircraft engine lip low-half section drawing forming method

A technology for aircraft engines and forming molds, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven cross-section change and deformation, poor molding effect, loose edges, etc., to reduce stress relaxation and material processing. Hardening, uniform effect of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

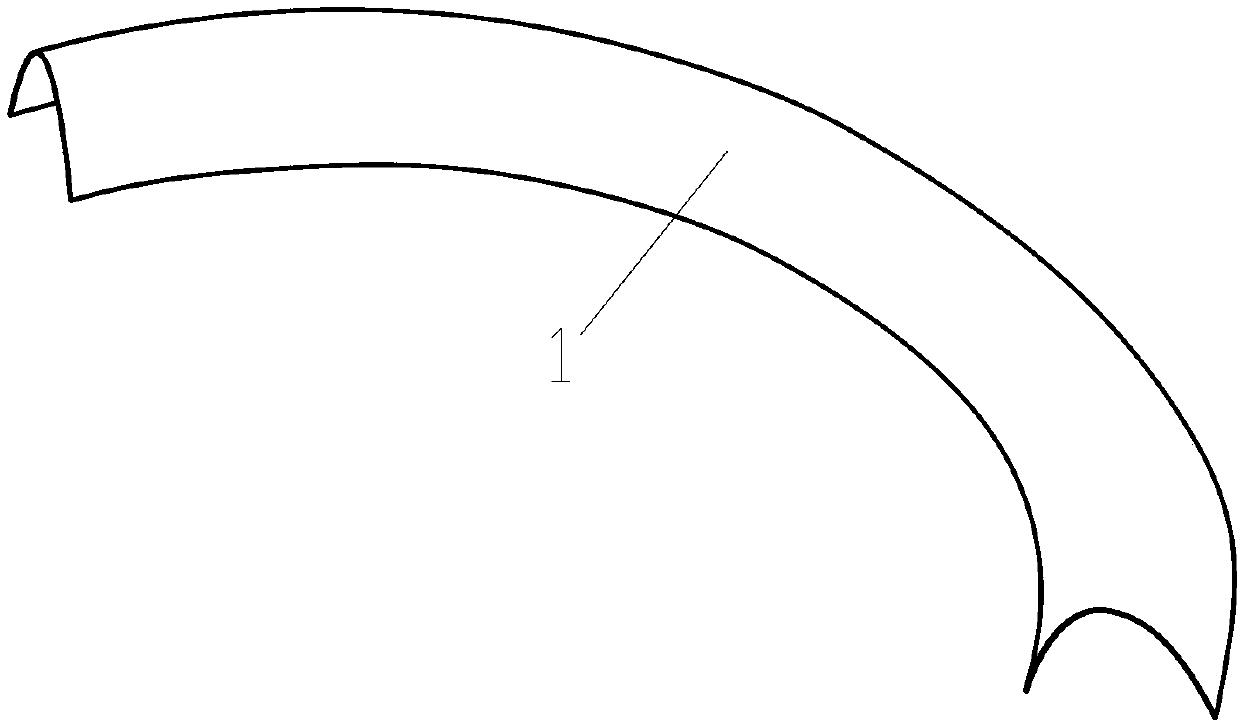

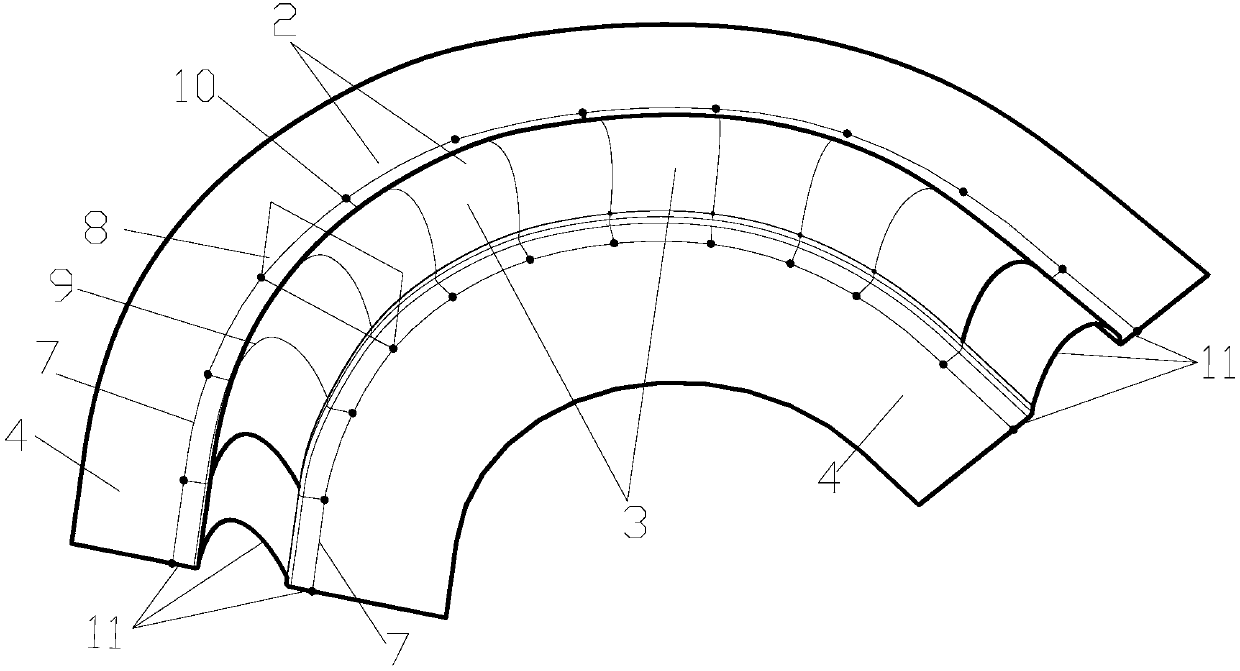

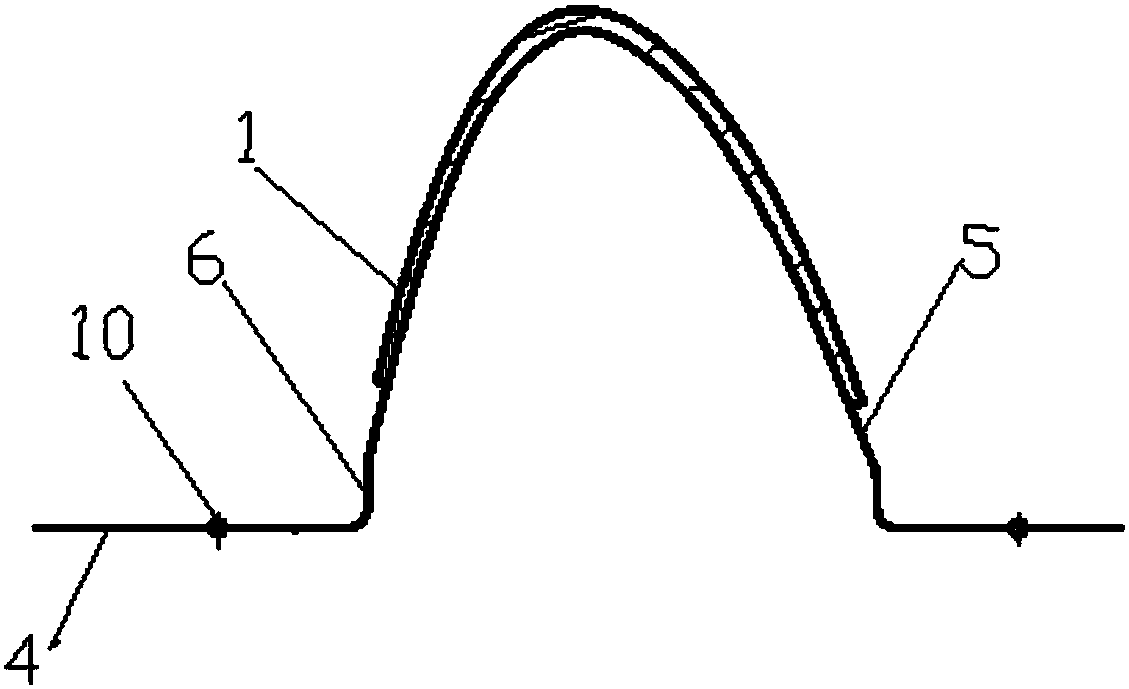

[0020] Refer to attached figure 1 , figure 1 Shown is the theoretical model 1 of the lower half of the aircraft engine lip, its structure is approximately C-shaped and is a parabolic shape with variable cross-section. The existing drawing methods for high-strength materials with variable section and variable curvature shape mainly have the following defects: first, the drawing extension ratio of each section is greatly different, and the degree of deformation is inconsistent, and the forming stress relaxation and edge looseness affect the mold attachment accuracy; second, the material strength is high. , The deformation resistance is large, and the plastic deformation is insufficient, which affects the accuracy of the molding; the third is that the material is deformed and hardened, and the springback caused by unloading stress release is difficult to repair.

[0021] In order to overcome the forming defects of the lower part of the engine lip above, refer to the attached fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com