Anchoring method and end-bearing anchor

An anchoring method and anchor rod technology, applied in construction, sheet pile walls, foundation structure engineering, etc., to achieve the effects of reducing project costs, speeding up project progress, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

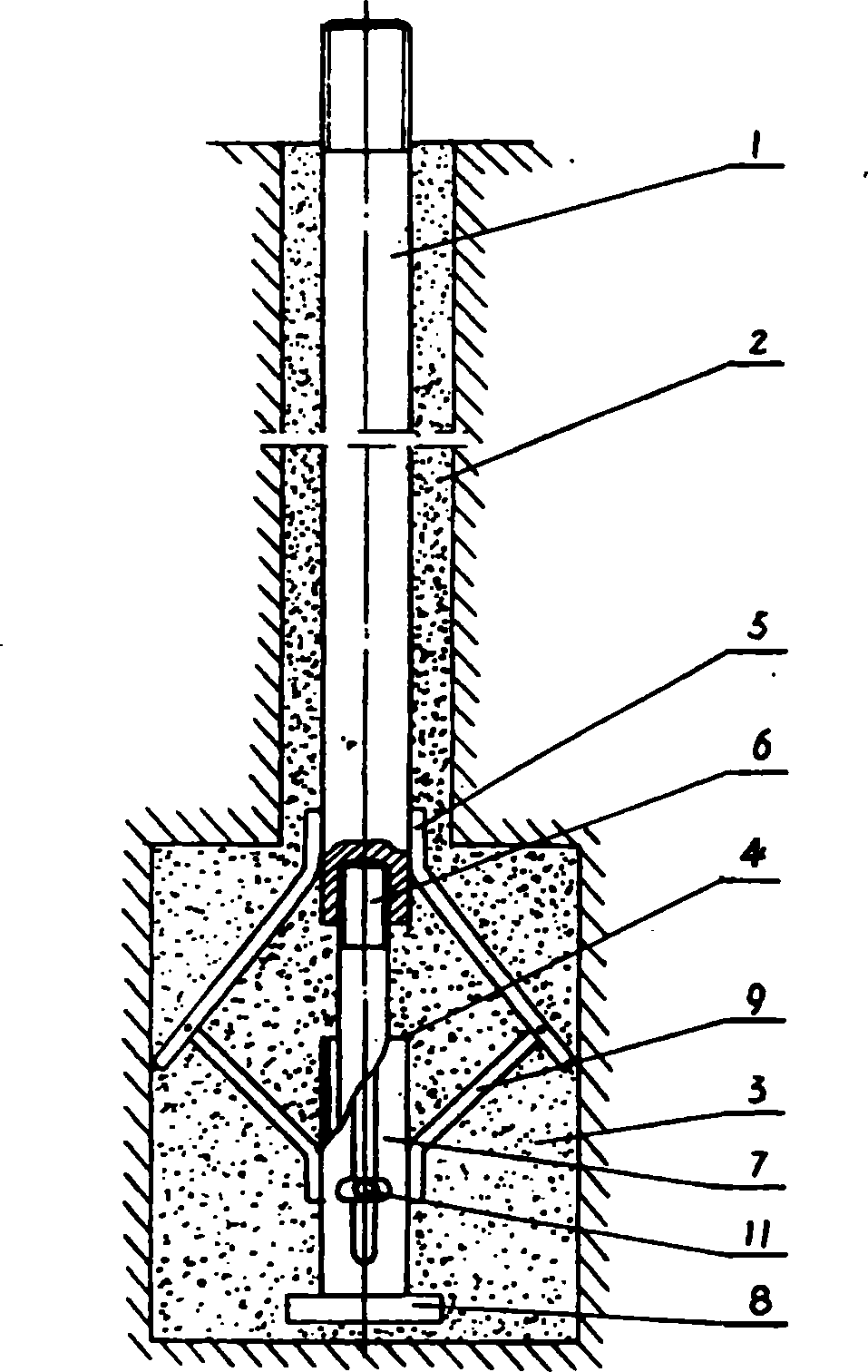

[0033] Such as figure 2 As shown, the present embodiment includes an anchor rod 1 arranged in an anchor hole 2, and is characterized in that an anchor head 4 is set under the anchor rod 1, which includes a sliding rod 7 and a stressed pull rod 5, and the stressed pull rod 5 can be used under external force Stretch under action, be located at the anchor rod 1 bottom, can set one or more than one, be directly welded on the anchor rod 1 or be fixed on the anchor rod 1 by bolt. Below the anchor rod 1, a sliding rod 7 is provided, which is placed in the anchor reaming hole 3 provided below the anchor hole 2. The sliding rod 7 is tubular, and its pipe wall is symmetrically provided with a long chute. The lower end of the upper sliding rod 6 is sleeved in the lower end of the lower sliding rod 7, and the pin rod 11 is fixed on the lower end of the upper sliding rod 6, and can pass through the chute of the lower sliding rod 7, driving the upper sliding rod 6 to move up and down in th...

Embodiment 2

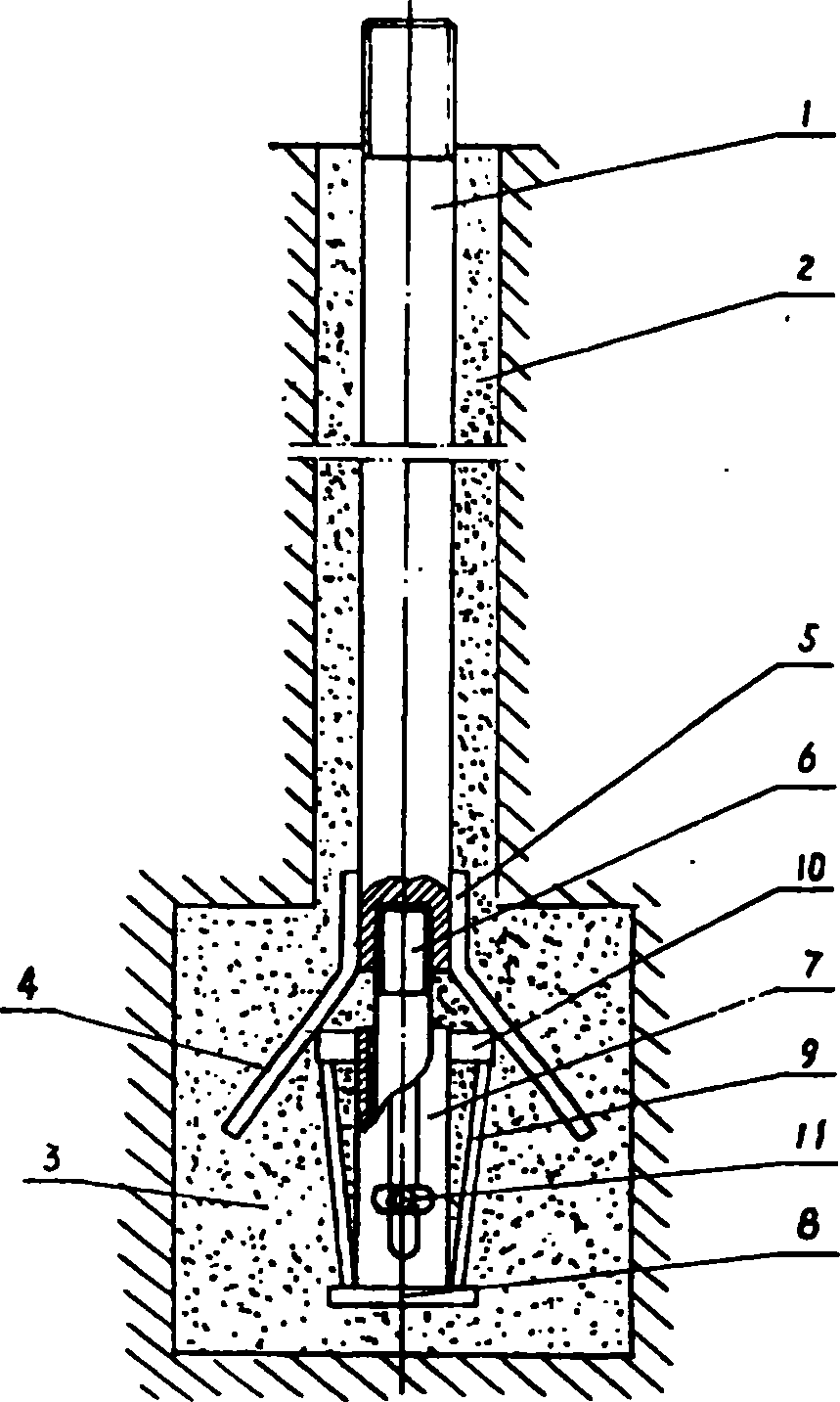

[0036] Such as image 3 As shown, the present embodiment includes an anchor rod 1 arranged in an anchor hole 2, and is characterized in that an anchor head 4 is set under the anchor rod 1, which includes a sliding rod 7 and a stressed pull rod 5, and the stressed pull rod 5 can be used under external force Stretch under action, be located at the anchor rod 1 bottom, can establish one or more than one, be directly welded on the anchor rod 1 or be fixed on the anchor rod 1 by screw. Below the anchor rod 1, a sliding rod 7 is provided, which is placed in the anchor reaming hole 3 provided below the anchor hole 2. The sliding rod 7 is tubular, and its pipe wall is symmetrically provided with a long chute. The lower end of the upper sliding rod 6 is sleeved in the lower end of the lower sliding rod 7, and the pin rod 11 is fixed on the lower end of the upper sliding rod 6, and can pass through the chute of the lower sliding rod 7, driving the upper sliding rod 6 to move up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com