A kind of non-curing rubber asphalt waterproof coating and preparation method thereof

A technology of asphalt waterproof coating and non-curing rubber, applied in asphalt coatings, wax coatings, coatings, etc., can solve the problems of inconspicuous non-curing characteristics, poor high temperature performance of materials, easy sliding of waterproof membranes, etc., and achieve excellent construction. excellent extensibility, low cohesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

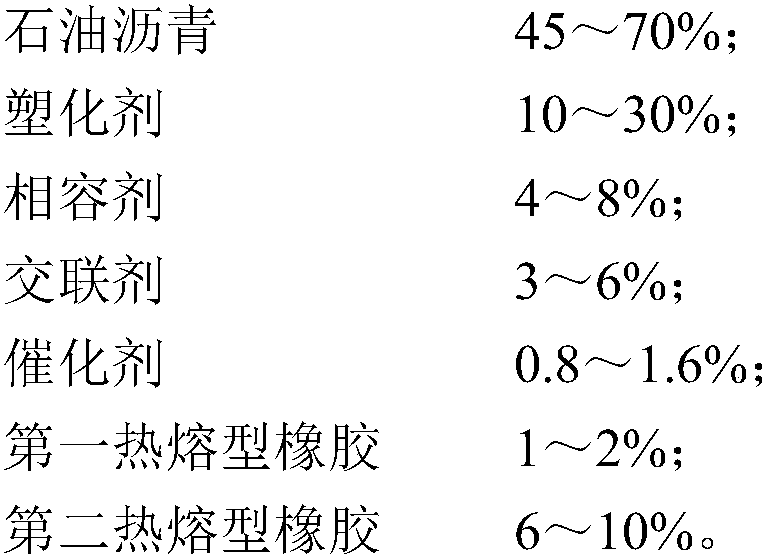

Method used

Image

Examples

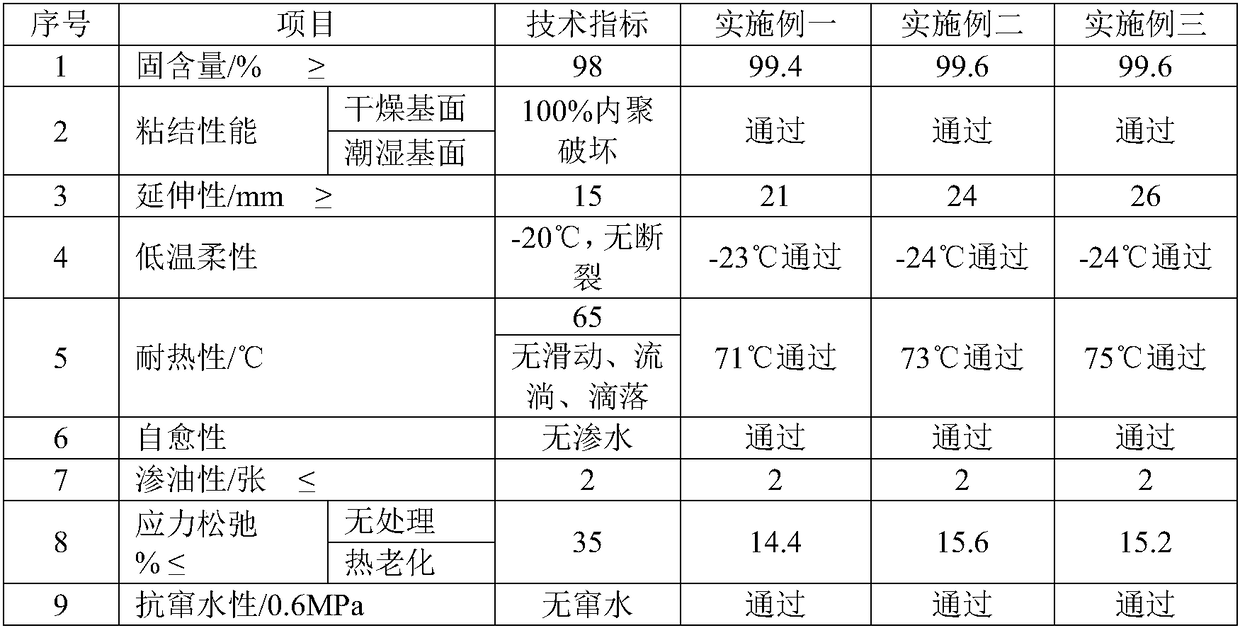

Embodiment 1

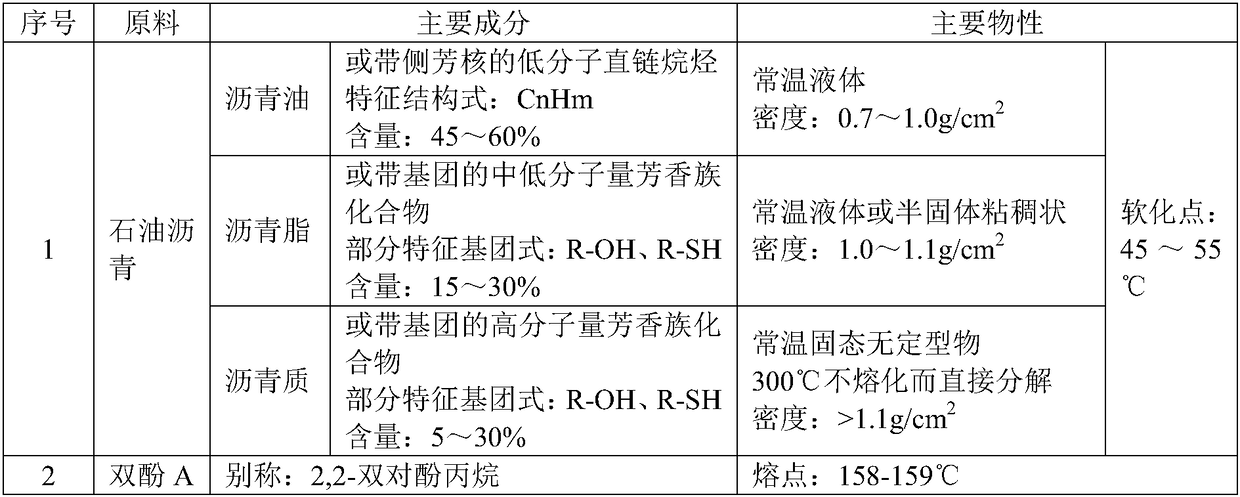

[0031] A non-curing rubber asphalt waterproof coating. The preparation process is as follows: add 67.8 parts of 90# petroleum asphalt, 16 parts of 46# machine oil, and 4.6 parts of refined paraffin into the stirring tank, heat it to 140-160 ° C, stir, and after 30 minutes, add 3.2 parts of bisphenol A, 1.2 parts of benzenesulfonic acid, react for 2 to 3 hours, test the high temperature resistance of the mixture (65 ° C, 2 hours without flowing), after meeting the requirements, raise the temperature to 180 ~ 200 ° C, continue to stir, add 1.2 parts SBS1401, 6 parts of SBR rubber powder, after about 1.5 hours, use a glass rod dipped in the material to visually inspect, if there are no particles, it means that the dispersion is uniform, otherwise it is necessary to continue stirring until there are no particles, and then test the high temperature performance of the coating, and turn off the heating after reaching the standard. Cool to about 120°C and pack.

Embodiment 2

[0033] A non-curing rubber asphalt waterproof coating. The preparation process is as follows: add 60 parts of 70# petroleum asphalt, 19 parts of 32# machine oil, and 5.1 parts of semi-refined paraffin into a stirring tank, heat it to 140-160 ° C, stir, and after 30 minutes, Add 4.6 parts of bisphenol A and 1.5 parts of benzenesulfonic acid, react for 2 to 3 hours, test the high temperature resistance of the mixture (65 ° C, 2 hours without flowing), after meeting the requirements, raise the temperature to 180 ~ 200 ° C, continue to stir, add 1.6 1 part of SBS1401, 8.2 parts of SBR rubber powder, after about 1.5 hours, visually inspect with a glass rod dipped in the material, if there are no particles, it means that the dispersion is uniform, otherwise you need to continue stirring until there are no particles, then test the high temperature performance of the coating, and turn off the heating after reaching the standard , cooled to about 120°C and discharged for packaging.

Embodiment 3

[0035] A non-curing rubber asphalt waterproof coating. The preparation process is as follows: add 51 parts of 90# petroleum asphalt, 25.5 parts of 46# mechanical oil, and 6.4 parts of refined paraffin into the stirring tank, heat it to 140-160 ° C, stir, and after 30 minutes, add 5.4 parts of bisphenol A, 1.5 parts of benzenesulfonic acid, react for 2 to 3 hours, test the high temperature resistance of the mixture (65 ° C, 2 hours without flowing), after meeting the requirements, raise the temperature to 180 ~ 200 ° C, continue to stir, add 1.8 parts SBS1401, 8.4 parts of SBR rubber powder, after about 1.5 hours, use a glass rod dipped in the material to visually inspect, if there are no particles, it means that the dispersion is uniform, otherwise it is necessary to continue stirring until there are no particles, and then test the high temperature performance of the coating, and turn off the heating after reaching the standard. Cool to about 120°C and pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com