PDMS-KIT-6 composite membrane for separating organic steam and preparation method thereof

A PDMS-KIT-6, KIT-6 technology, applied in the field of membrane separation, can solve the problems of low air permeability rate, low air permeability selectivity, and difficulty in ultra-thinning, and achieve low cost, uniform distribution, and good selective permeation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

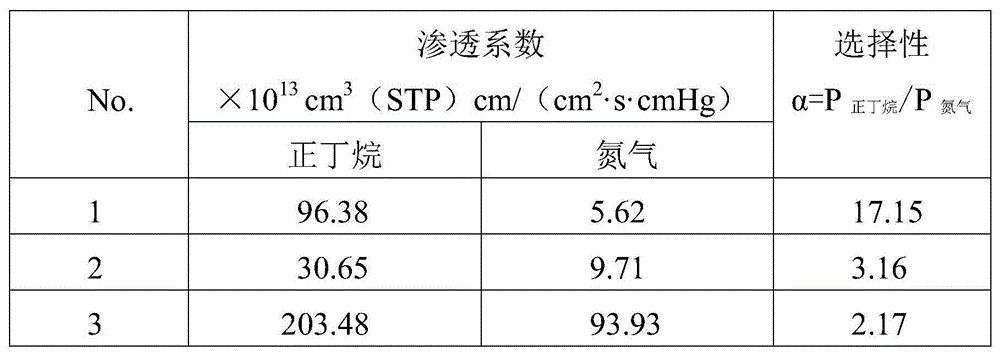

Embodiment 1

[0030] The preparation method of the present embodiment is realized like this, comprises the following steps:

[0031] (1) According to the literature (Kim, T.M.et al.J.Am.Chem.Soc., 2005, 127, 7601): Add 11.2g of HCL (37%) into 217mL of ultrapure water in a water bath at 35°C, and then Add 6g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (hereinafter referred to as P123), after P123 is completely dissolved, add 6g of n-butanol and 12.9g of tetraethyl orthosilicate (hereinafter referred to as TEOS), stirred vigorously for 24 hours, then transferred to a high-pressure reactor, and heated at 100°C for 24 hours. The obtained solid product was suction filtered, washed, and dried overnight at 100°C. Subsequently, the white powder was washed with ethanol and a small amount of hydrochloric acid at 60° C. for 12 h, filtered with suction, and dried overnight at room temperature after washing. Finally, it was calcined at 550°C for 4h (heating rate: 5°...

Embodiment 2

[0037] The preparation method of the present embodiment is realized like this, comprises the following steps:

[0038] (1) According to the literature (Kim, T.M.et al.J.Am.Chem.Soc., 2005, 127, 7601): Add 11.2g of HCL (37%) into 217mL of ultrapure water in a water bath at 35°C, and then Add 6g of P123, after the P123 is completely dissolved, add 6g of n-butanol and 12.9g of TEOS, stir vigorously for 24h, transfer to a high-pressure reactor, and heat at 100°C for 24h. The obtained solid product was suction filtered, washed, and dried overnight at 100°C. Subsequently, the white powder was washed with ethanol and a small amount of hydrochloric acid at 60° C. for 12 h, filtered with suction, and dried overnight at room temperature after washing. Finally, it was calcined at 550°C for 4h (heating rate: 5°C / min), and KIT-6 mesoporous molecular sieve material was finally obtained.

[0039] (2) The synthesized KIT-6 mesoporous molecular sieve was vacuum degassed at 150°C for 24 hours...

Embodiment 3

[0044]The preparation method of the present embodiment is realized like this, comprises the following steps:

[0045] (1) According to the literature (Kim, T.M.et al.J.Am.Chem.Soc., 2005, 127, 7601): Add 11.2g of HCL (37%) into 217mL of ultrapure water in a water bath at 35°C, and then Add 6g of P123, after the P123 is completely dissolved, add 6g of n-butanol and 12.9g of TEOS, stir vigorously for 24h, transfer to a high-pressure reactor, and heat at 100°C for 24h. The obtained solid product was suction filtered, washed, and dried overnight at 100°C. Subsequently, the white powder was washed with ethanol and a small amount of hydrochloric acid at 60° C. for 12 h, filtered with suction, and dried overnight at room temperature after washing. Finally, it was calcined at 550°C for 4h (heating rate: 5°C / min), and KIT-6 mesoporous molecular sieve material was finally obtained.

[0046] (2) The synthesized KIT-6 mesoporous molecular sieve was vacuum degassed at 150°C for 24 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com