Mounting method of precast air duct during construction stage of construction engineering structure

A construction stage and construction engineering technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of difficult handling of details, affecting waterproof construction, and excessive use of materials, so as to avoid hidden dangers of floor leakage and eliminate leakage Hidden dangers, the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

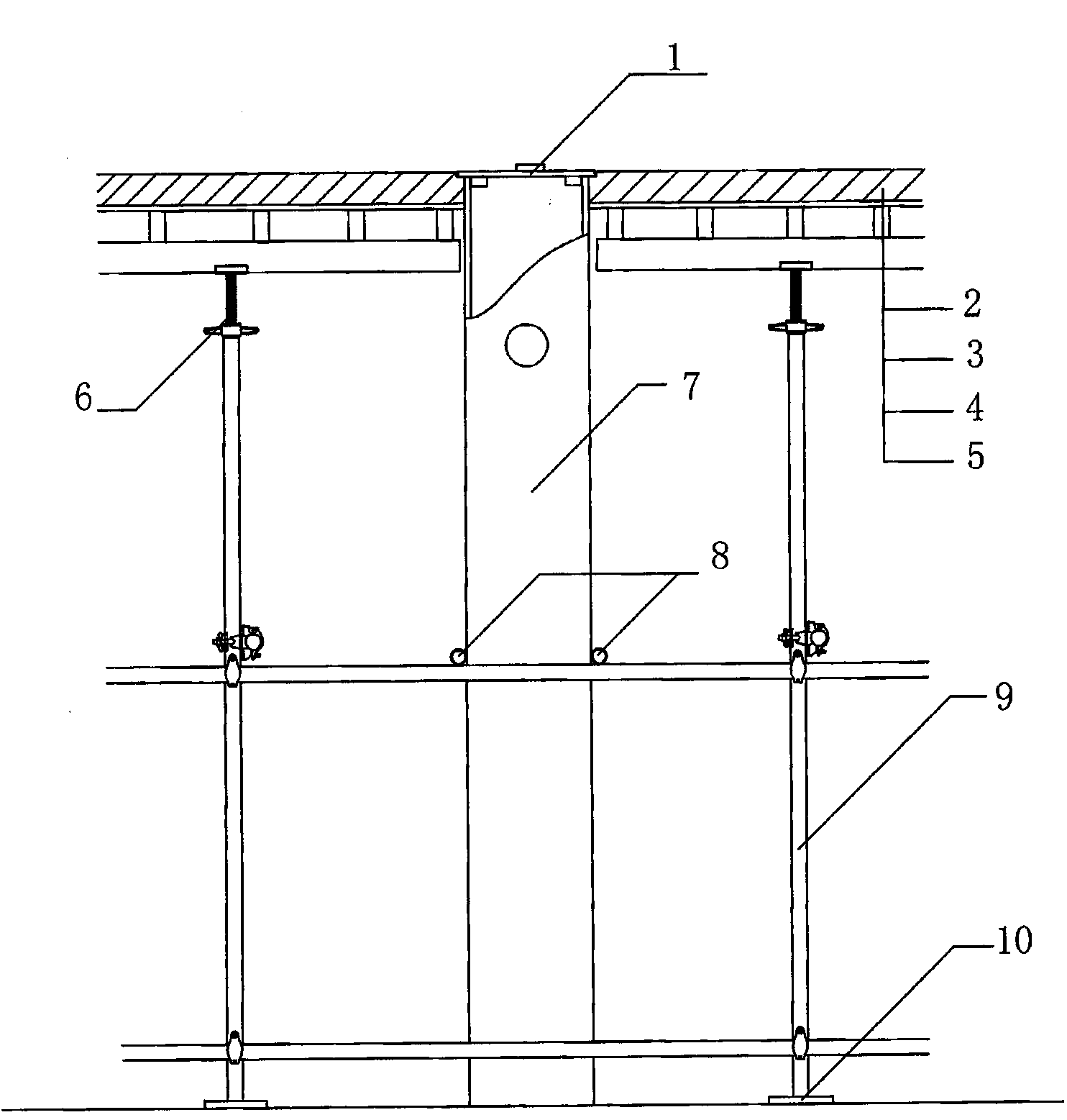

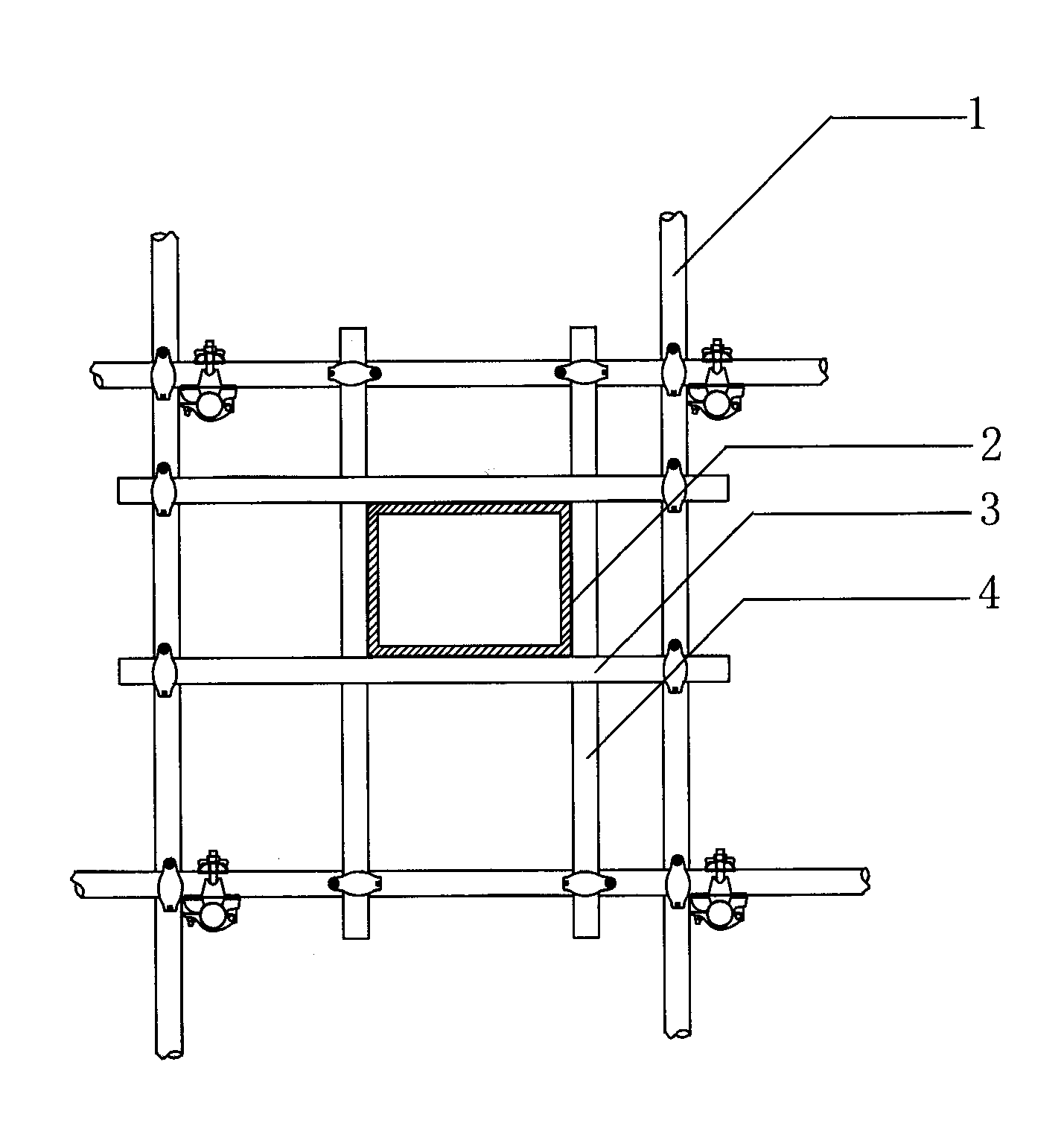

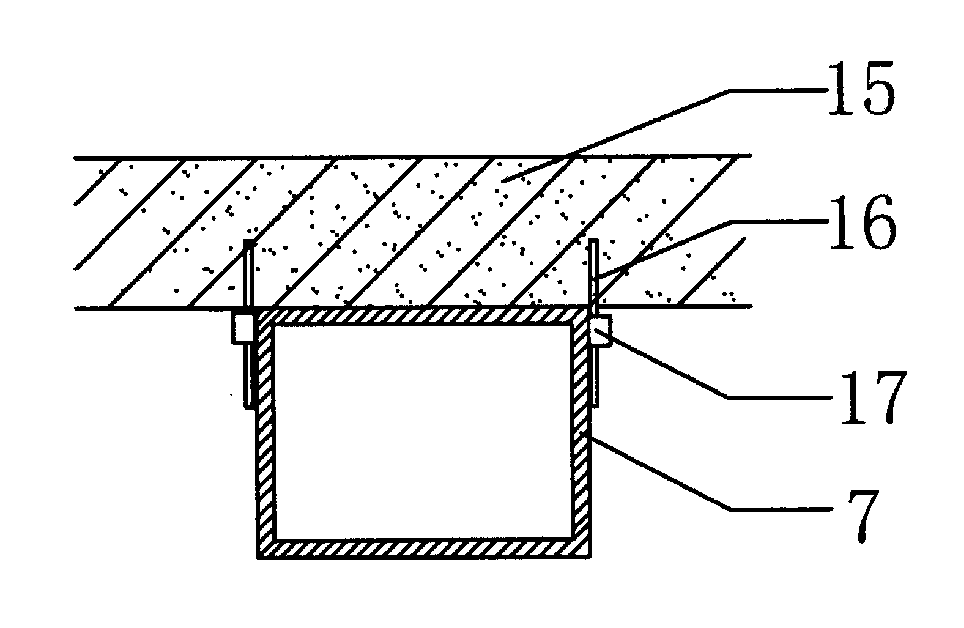

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0031] The prefabricated smoke duct installation technology in the construction stage of the construction project is based on the on-site assembly of the bottom form of the floor slab, and the installation of the smoke duct is interspersed with the construction process. In the installation preparation process, first order the smoke duct 7 and make the temporary cover plate 1 for the smoke duct on site. The model and cross-sectional size of the smoke duct meet the design requirements. The length of the smoke duct on the first floor = floor height - 20mm, and the length of the smoke duct on each floor above the second floor = floor height - 5mm. The temporary cover plate is made of existing materials on site (such as bamboo plywood, multi-layer film-coated board or wooden board), and the size of the panel 12 of the cover plate is 30mm larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com