Rear-end gear chamber structure of diesel engine

A technology for gear chambers and diesel engines, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of difficult manufacturing, difficult to assemble, inconvenient to maintain and adjust, etc., and achieves low manufacturing difficulty, easy assembly, and reduced manufacturing difficulty. effect on cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

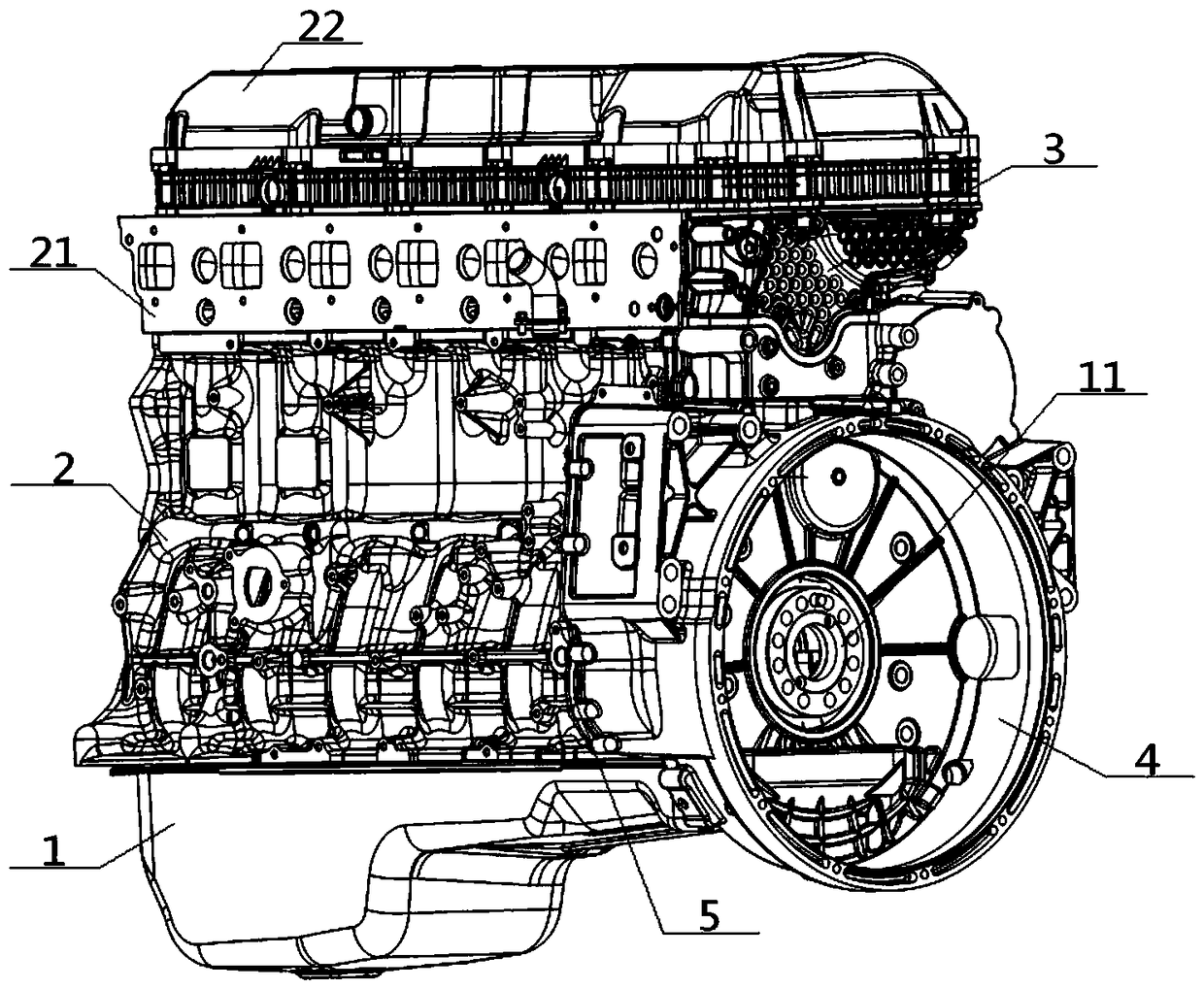

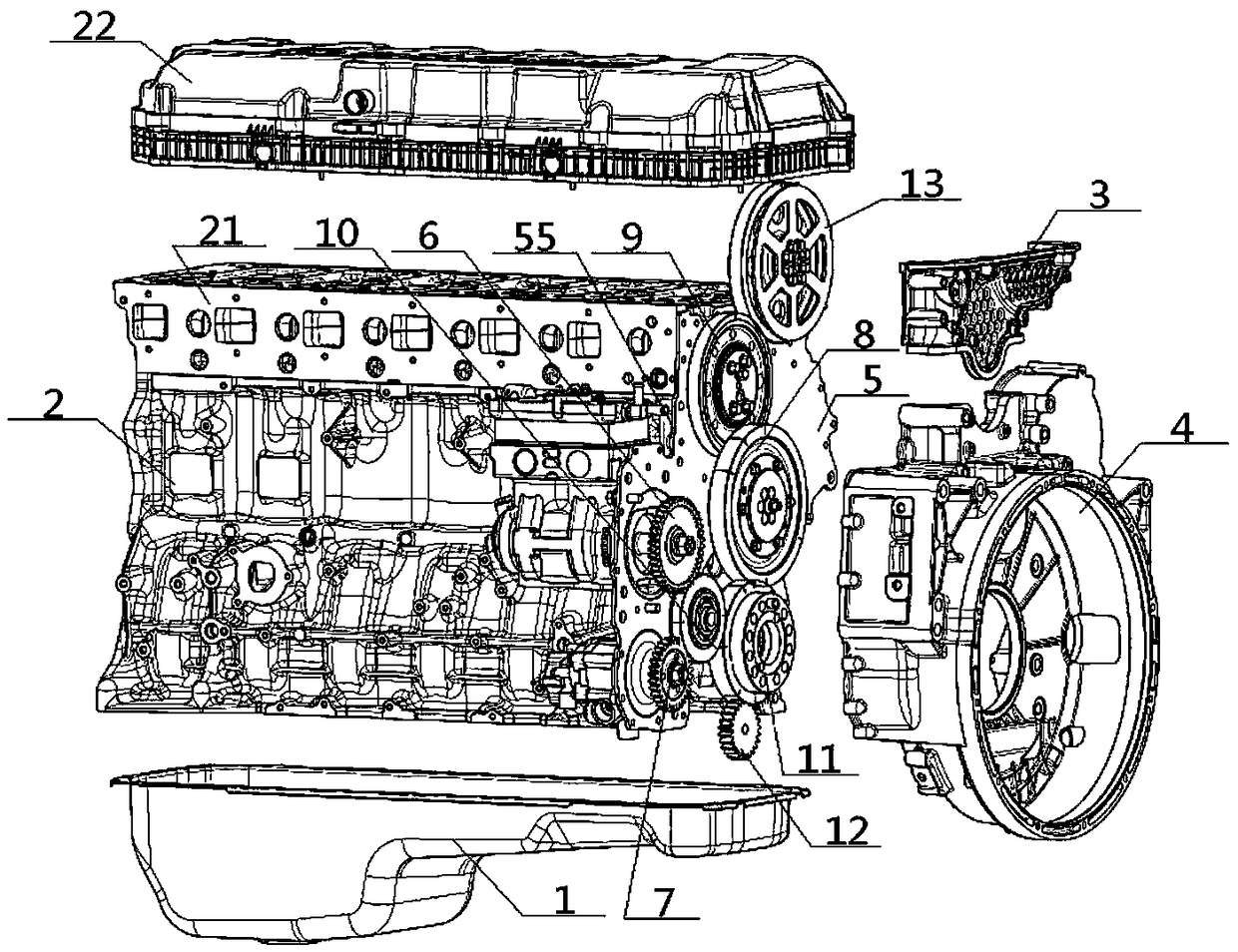

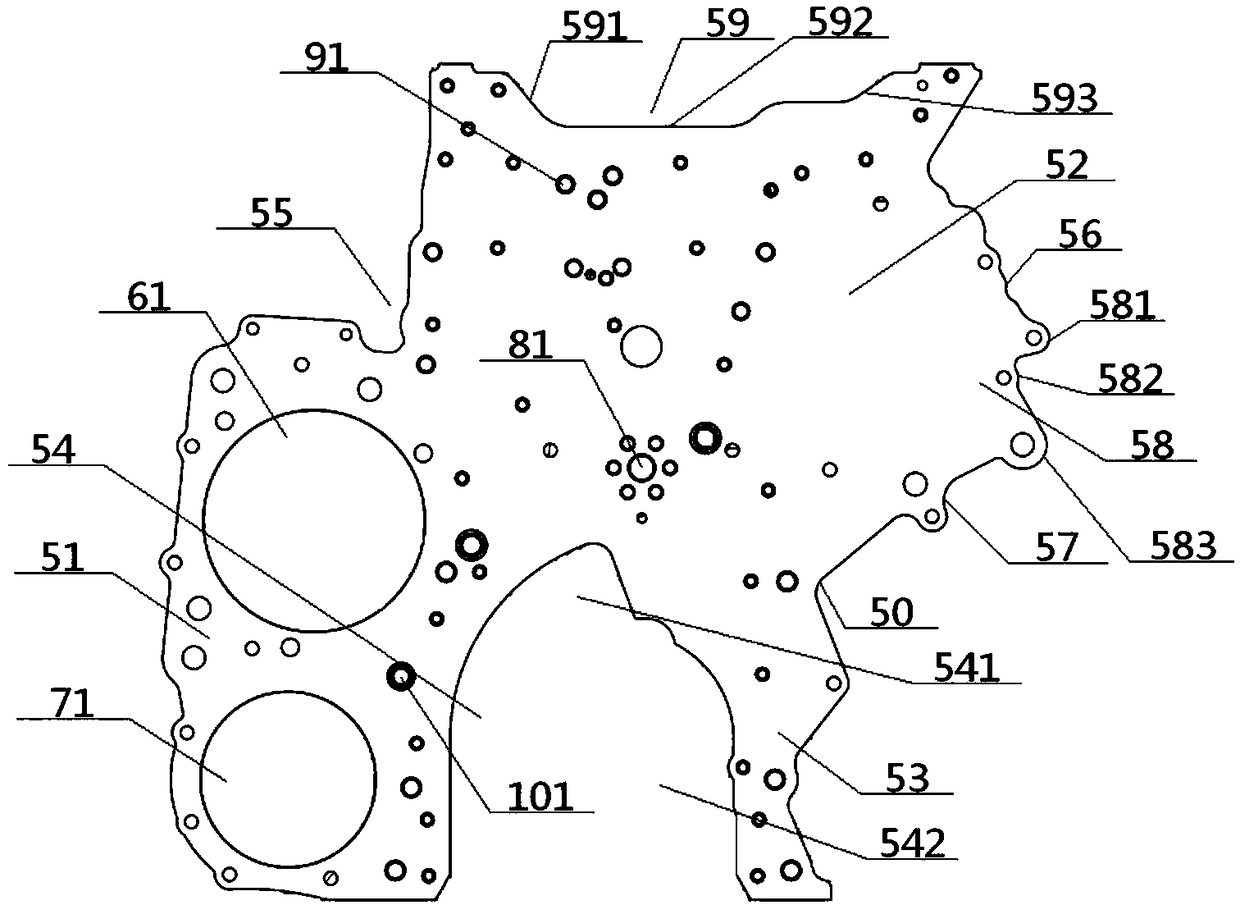

[0063] see Figure 1 to Figure 13 , a rear end gear chamber structure of a diesel engine, comprising a cylinder block 2, a cylinder head 21 and a timing gear chamber cover 3, a cylinder head 21 is arranged above the cylinder block 2, and the sides of the cylinder head 21 and the timing gear chamber cover The 3 sides of the diesel engine are connected; the rear gear chamber structure of the diesel engine also includes a rear end plate body 5 and a flywheel housing 4; the rear end plate body 5 includes a left plate body 51, an upper plate body 52 and a lower plate body 53, and the left The position near the top edge of the left plate body 51 on the right side of the plate body 51 is connected with the position near the bottom edge of the upper plate body 52 on the left side edge of the upper plate body 52, and the bottom edge of the upper plate body 52 is away from the left plate The position of the body 51 is connected with the top of the lower plate body 53, and the left side ...

Embodiment 2

[0065] Basic content is the same as embodiment 1, the difference is:

[0066]The middle part of the left plate body 51 is provided with an air compressor hole 61 and an oil pump hole 71 for corresponding installation with the air compressor gear 6 and the oil pump gear 7. The left plate body 51 is located between the air compressor hole 61 and the oil pump hole 71. There is No. 3 installation hole 101 on the position between them to install No. 3 falling gear 10; the position near the top of the bottom opening 54 on the upper plate body 52 is provided with No. 1 mounting hole 81 to install No. 1 falling gear 8, and the upper plate body The position between its top edge and the No. 1 mounting hole 81 on the 52 is provided with a No. 2 mounting hole 91 to install the No. 2 falling gear 9 . On the left plate body 51, there are empty upper left holes 611 and empty upper right holes 612 arranged side by side on the position between the top edge of the left plate body 51 and the top...

Embodiment 3

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] The middle part of the flywheel housing 4 is provided with a concave flywheel chamber 112, and the middle part of the flywheel chamber 112 is provided with a through crankshaft gear hole 111, and the back side of the flywheel housing 4 is provided with an oil bottom at the position directly below the crankshaft gear hole 111. The shell matching surface 14 is connected with the oil pan 1, and the top of the flywheel housing 4 is provided with a gear chamber cover fitting seat 31, the bottom surface of which is higher than the flywheel chamber 112, and the gear chamber cover fitting seat 31 The top surface is provided with a recessed gear chamber cover matching groove 32, and the gear chamber cover matching groove 32 is wedged with the lower extension end 33 of the cover embedded in it; the back of the flywheel housing 4 is located on the left side of the crankshaft gear hole 111 The parts on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com