Rear bumper mask assembly

A bumper and face mask technology, applied to bumpers and other directions, can solve problems such as unsightly appearance, and achieve the effects of reducing driving resistance, improving fluidity, and combining tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

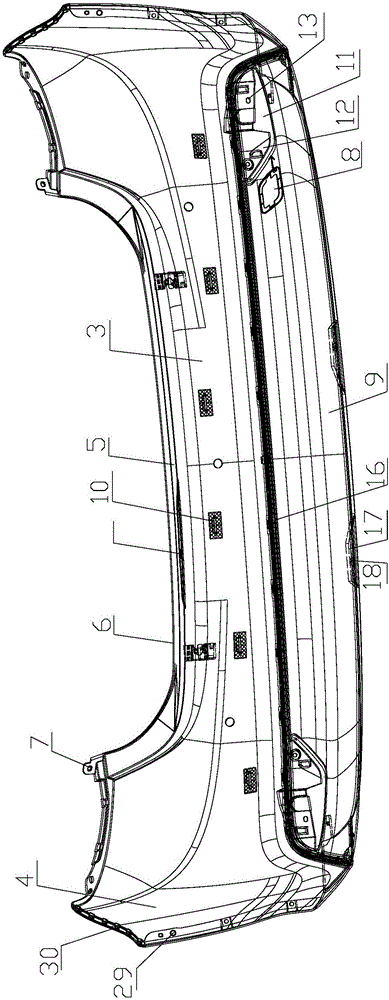

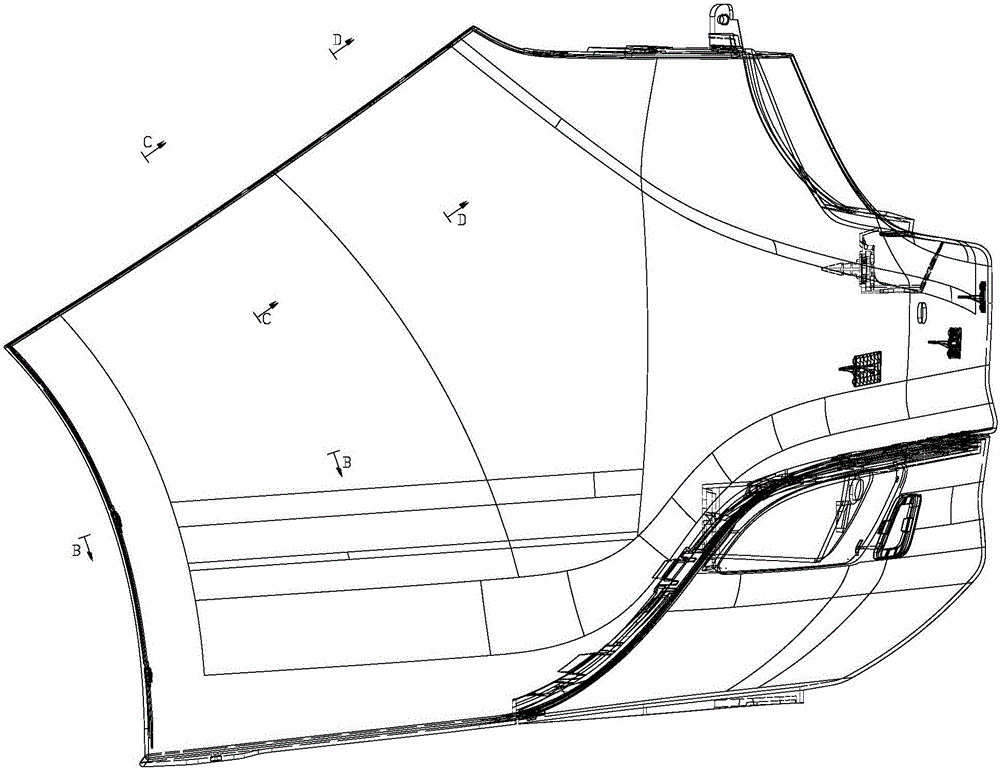

[0041] A rear bumper mask assembly is fixed on a vehicle 2 through a rear bumper beam 1 .

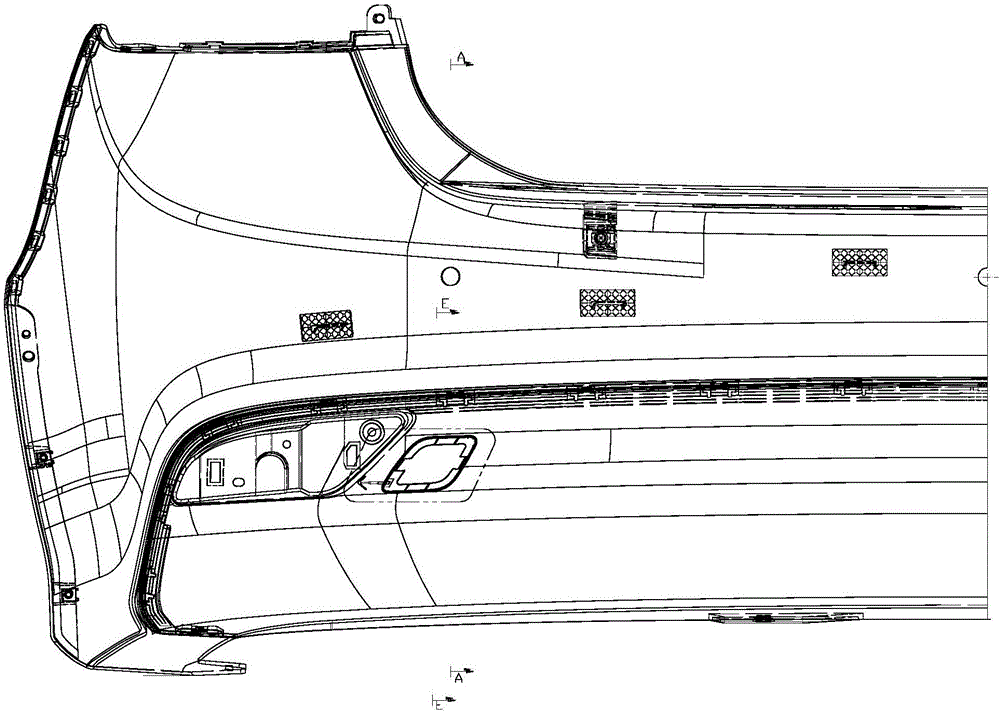

[0042] The rear bumper mask assembly includes a side panel 3 and a rear panel 4 , the rear panel 4 extends along the width direction of the vehicle 2 , and the rear panel 4 extends along the width direction of the vehicle 2 and bends toward both sides of the vehicle 2 A side panel 3 is formed around the vehicle body, and the upper part of the rear panel 4 is recessed inwardly to form a trunk lid receiving surface 5, and the inner edge of the trunk lid receiving surface 5 bulges upwards to form a trunk lid limit surface 6. The cooperation of the receiving surface of the trunk lid and the limit surface of the trunk lid can limit the closing position of the trunk lid;

[0043]The rear wall 4 is provided with a positioning hole 7, a combination lamp installation structure, a tow hook cover 8, a lower guard plate 9 and a wire harness fixing bracket 10. The positioning hole 7 is located above...

Embodiment 2

[0050] The rear bumper mask assembly of the present invention is tested, and the testing environment is: ambient temperature (23±2)° C., ambient humidity (50±5)% RH.

[0051] (1) Chemical resistance

[0052] Detection conditions: reagents: white gasoline; windshield detergent; white kerosene

[0053] Test method: dip the above chemicals with cotton wool and apply it on the surface of the sample at a wiping speed of 100mm / s, 8 times in the vertical and horizontal directions respectively, and leave it for 1 hour.

[0054] test numbers

skills requirement

Test results

in conclusion

3pcs

Appearance is normal

No abnormality

conform to

[0055] (2) Insertion force of tow hook

[0056]

[0057] (3) Pull-out force of lower guard plate

[0058] Testing conditions: 100N force is applied in the direction opposite to the installation direction of the part at the most protruding position on the surface of the part.

[0059]

[0060] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com