Energy-saving racing car frame

The technology of a frame and a support rod is applied in the field of lightweight and energy-saving vehicles, which can solve the problems of poor torsional performance of the angle tube, no application, and small section modulus, so as to achieve a compact structure, reduce driving resistance, and air resistance. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

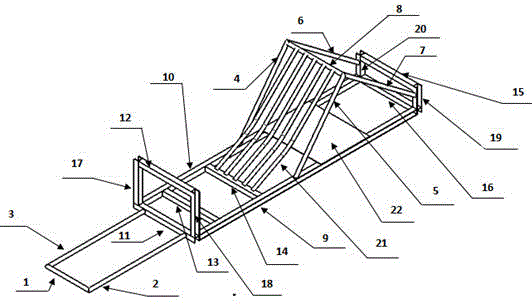

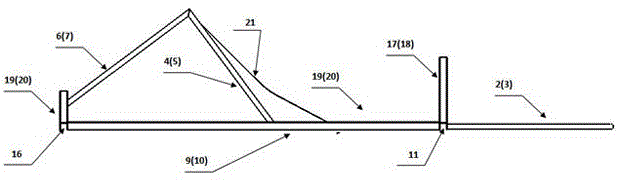

[0011] The overall structure of the energy-saving racing car frame of the present invention is as follows: figure 1 As shown, the energy-saving racing car frame of the present invention includes the first lower beam 11, the second lower beam 13, the third lower beam 14, the fourth lower beam 16, the first upper beam 12, the second upper beam 15, the second upper beam A longitudinal beam 9, a second longitudinal beam 10, a first column 17, a second column 18, a third column 19, a fourth column 20, a fourth support rod 4, a fifth support rod 5, a sixth support rod 6, a Seven support rods 7, the eighth support rod 8, seat belt 21, cross plate 22, wherein the two ends of the first lower cross beam 11, the second lower cross beam 13, the third lower cross beam 14, and the fourth lower cross beam 16 are respectively connected with The first longitudinal beam 9 and the second longitudinal beam 10 are connected, one end of the first upper beam 12 is connected with the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com