Envelope material durability testing equipment and method

A technology for testing equipment and enclosure materials, applied in the direction of analysis materials, measuring devices, weather resistance/light resistance/corrosion resistance, etc. No consideration of humidity conduction measurement and other issues, to achieve good fire performance, increase stability, and reduce the effect of cold bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

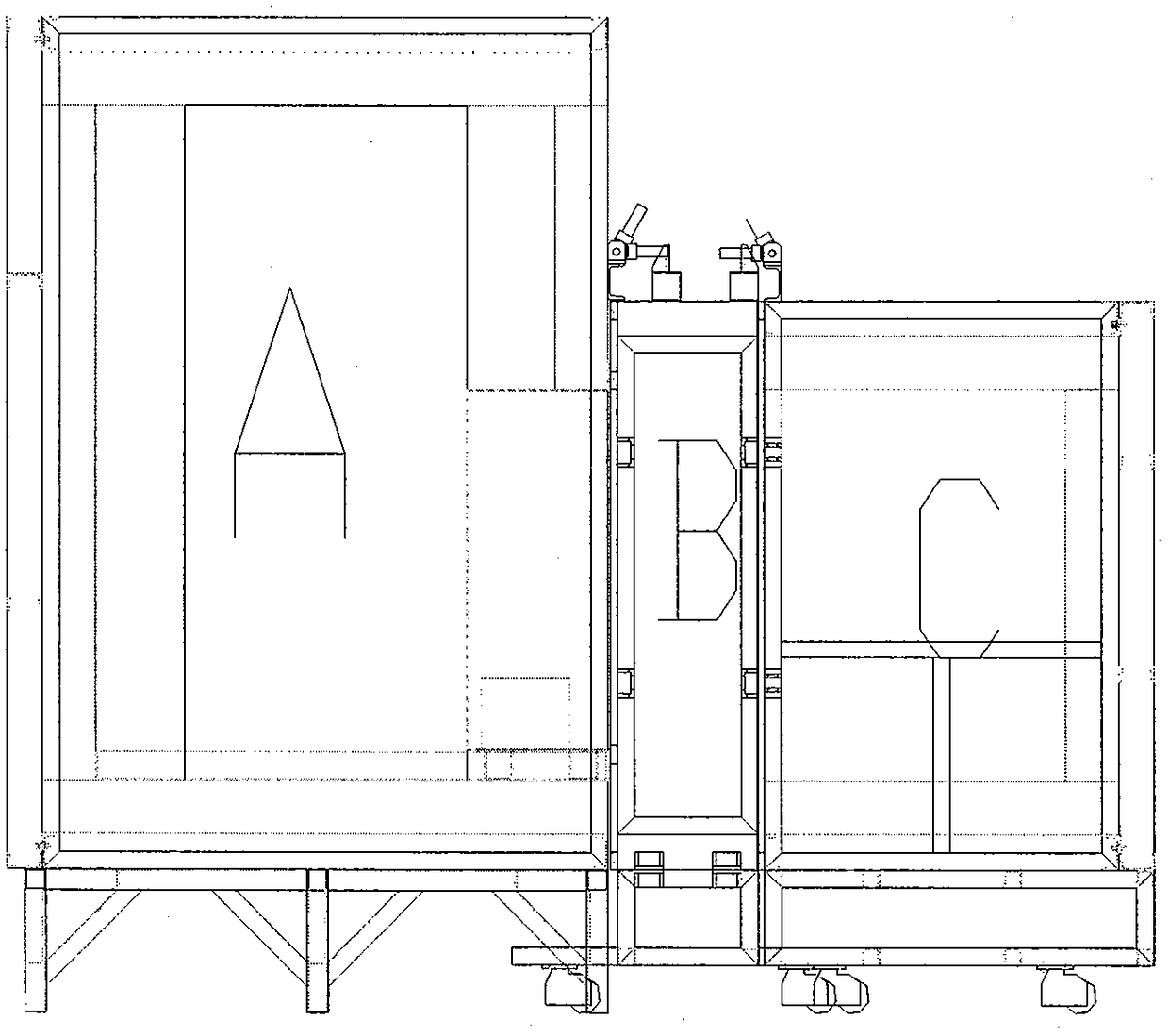

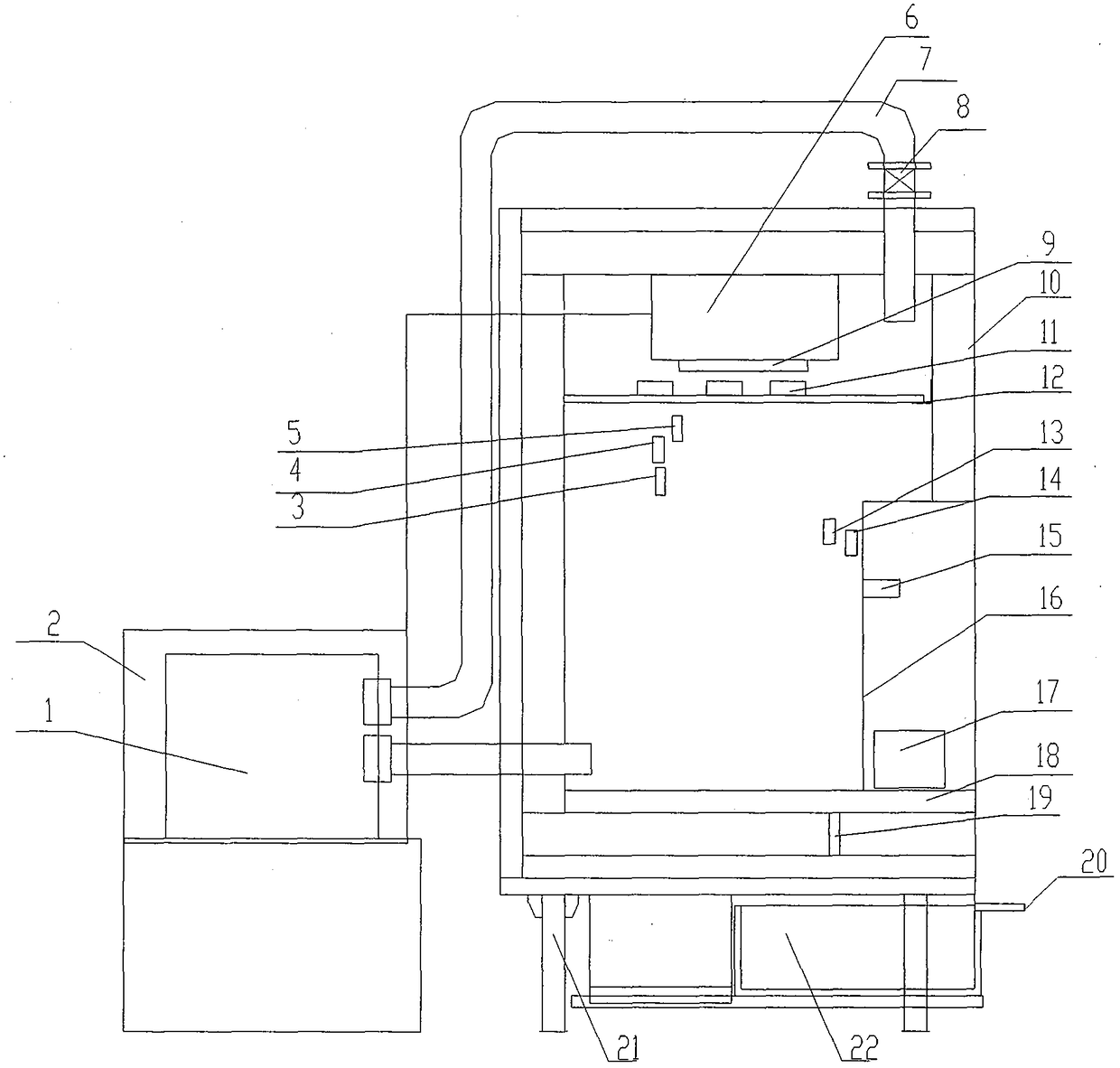

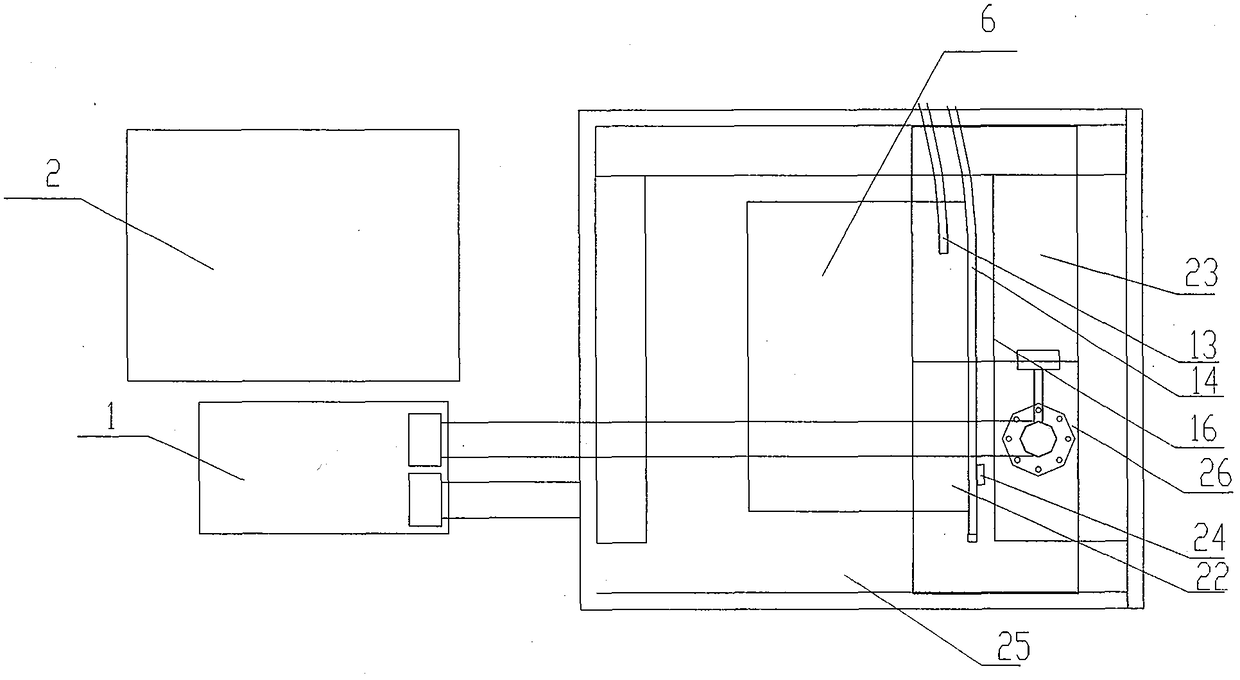

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The enclosure material durability testing equipment is mainly composed of an outdoor environmental chamber simulation system A, an indoor environmental chamber simulation system C, a specimen frame system B, a moisture transfer weight acquisition system, and an automatic control and data acquisition system. Each system contains Humidity control, temperature control, rain, weighing and other functions, data are collected from time to time and recorded and processed. like figure 1 As shown, the outdoor environment chamber simulation system A is connected to one side of the specimen frame system B, the other side of the specimen frame system B is connected to the indoor environment chamber simulation system C, and the moisture transfer weight acquisition system is placed in the outdoor environment chamber simulation system middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com