Amorphous alloy round pipe extrusion forming device and technology

An amorphous alloy, extrusion forming technology, applied in the direction of metal extrusion, metal extrusion die, metal extrusion control equipment, etc., can solve problems such as the inability to complete the extrusion forming process of amorphous alloy round tubes, To achieve the effect of avoiding mold surface damage or overall destruction, avoiding crystallization and oxidation, and facilitating disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

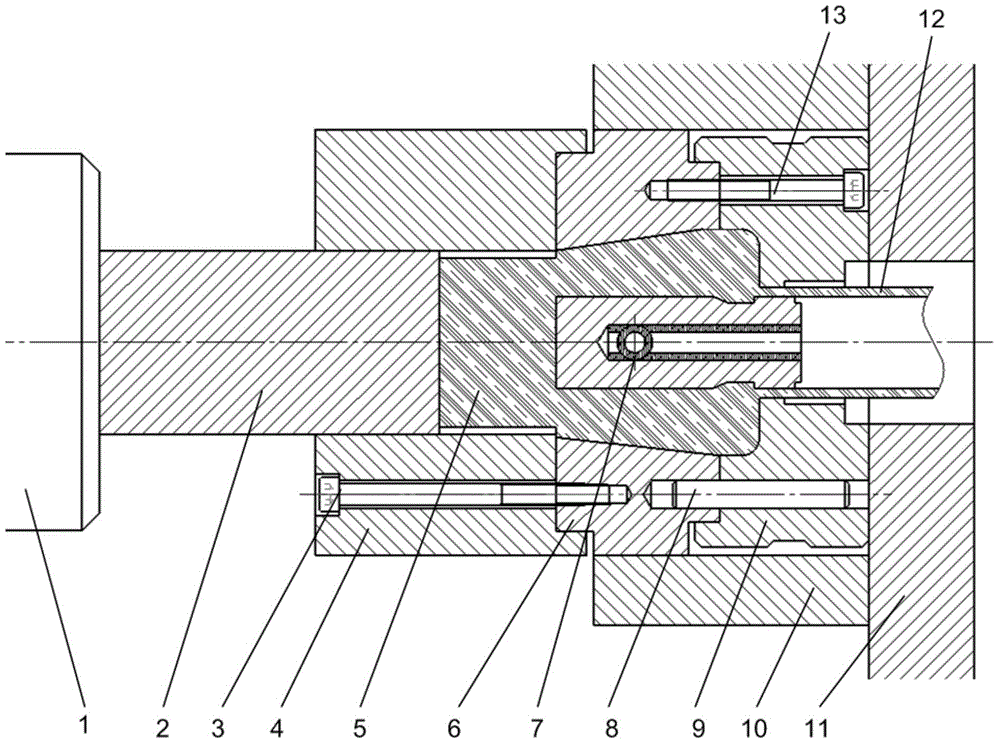

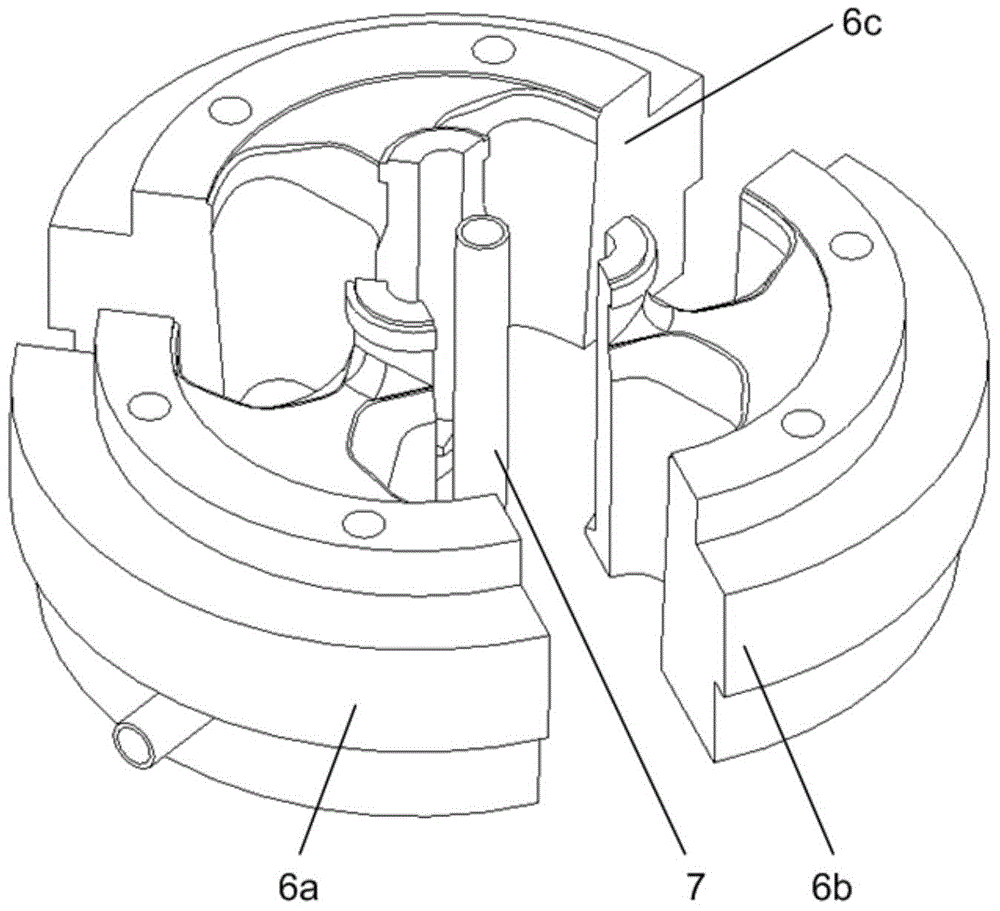

[0038] An amorphous alloy circular tube extrusion forming device, comprising a hydraulic extrusion structure 1, an extrusion die, and an extrusion tooling frame 11, and the extrusion die includes an extrusion punch 2, an extrusion barrel 4, and an extrusion die 6. The shaping sleeve 9, the extrusion cylinder 4, the extrusion die 6, and the shaping sleeve 9 are sequentially connected and fixed together. The cavity formed in the extrusion die has four parts: a blank chamber, a shunting chamber, a welding chamber and a forming chamber. The extrusion die 6 is designed as a block structure, and the joint line of each block is selected at the welding chamber. The extrusion die 6 is covered with an extrusion die clamping sleeve 10, and the outer extrusion die The surface is combined with the inner surface of the extrusion die clamping sleeve 10 in the form of a progressive tapered surface, and the extrusion die clamping sleeve 10 is fixed on the extrusion tooling frame 11 .

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com