Three lips contact type seal bearing

A contact-type sealing and bearing technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as the reduction of sealing performance, and achieve the effect of improving sealing performance, reducing package capacity and prolonging working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

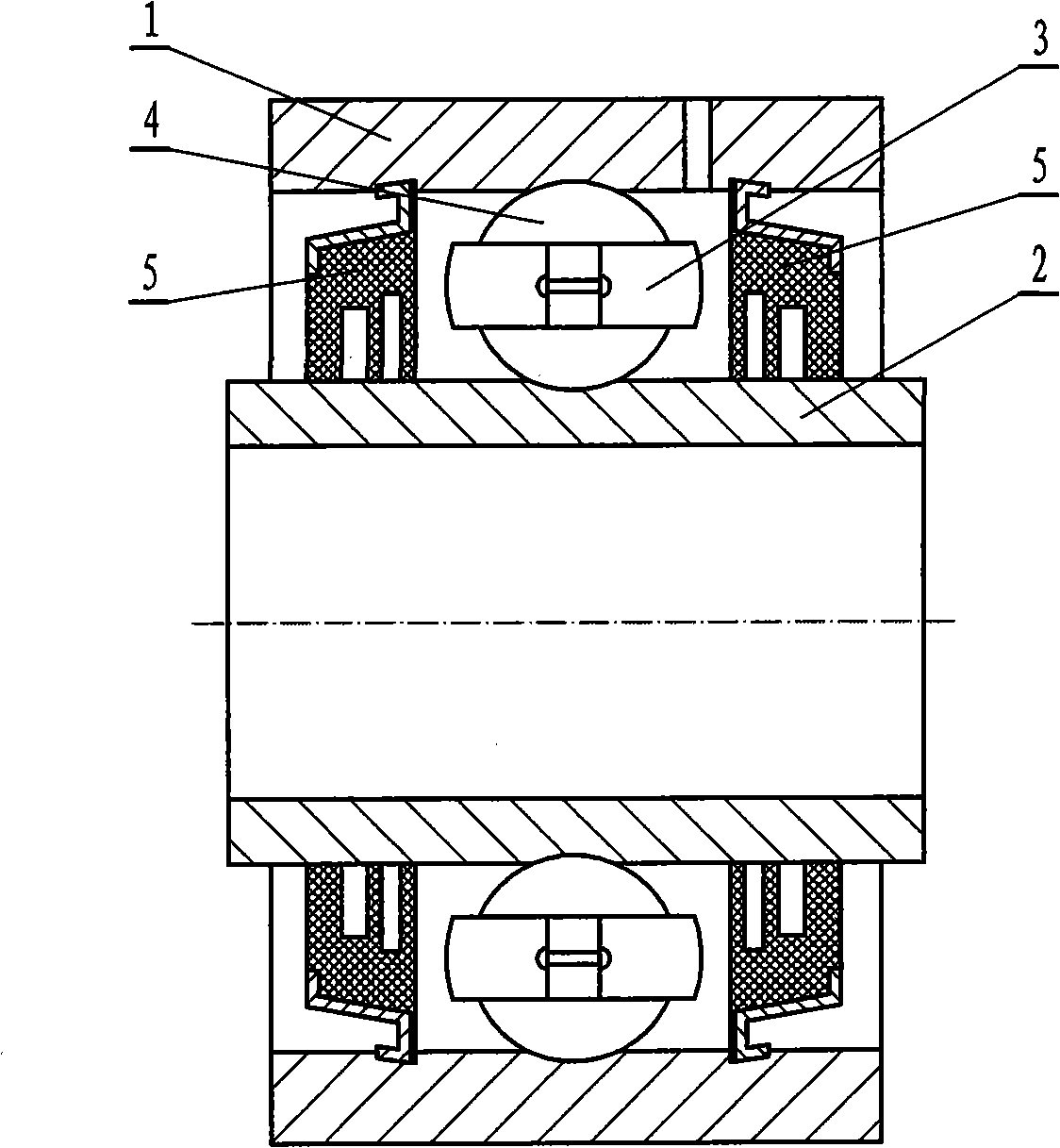

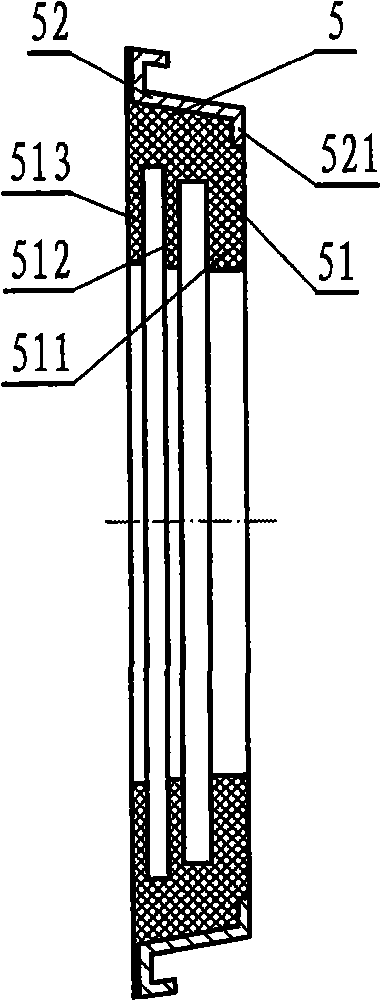

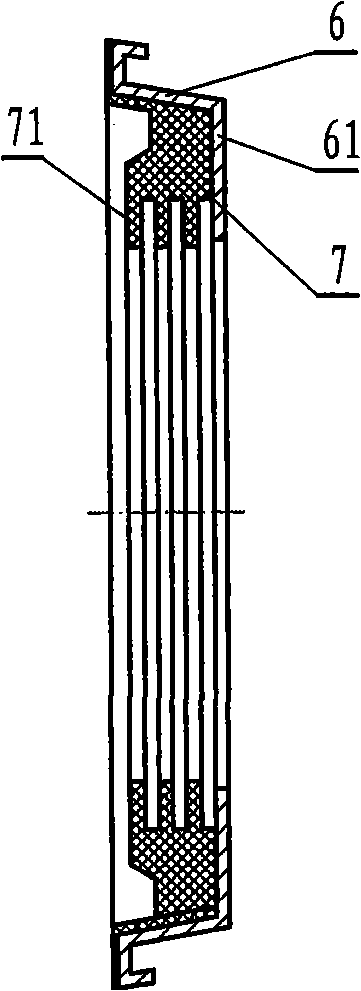

[0013] Such as figure 1 figure 2 The three-lip contact sealed bearing shown has bearing outer ring 1, bearing inner ring 2, cage 3, rolling elements 4, sealing ring 5, and the outer ring of sealing ring 5 is embedded and fixed on the inner surface of bearing outer ring 1 , the number of sealing rings 5 is two, symmetrically arranged with respect to the rolling elements 4, the sealing ring 5 has a sealing member 51 and a skeleton 52, and there are three contact lips 511, 512 arranged in parallel on the inner periphery of the sealing member 51, 513, the three contact lips 511, 512, 513 are in close contact with the outer diameter surface of the bearing inner ring 2, and the unilateral interference between the contact lips 511, 512, 513 and the outer diameter surface of the bearing inner ring 2 is 1.5mm, which can make the contact The lips 511, 512, 513 are more tightly combined with the outer diameter surface of the bearing inner ring 2, and the thickness of the outermost c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com