NiSe2-CoSe2/CFs composite material with micro-nano two-stage pores and high structural stability and preparation of NiSe2-CoSe2/CFs composite material

A composite material and double-stage pore technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of active phase structure instability, short service life of electrodes, etc., to achieve rich active sites, rich super-gas repellency, The effect of excellent mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

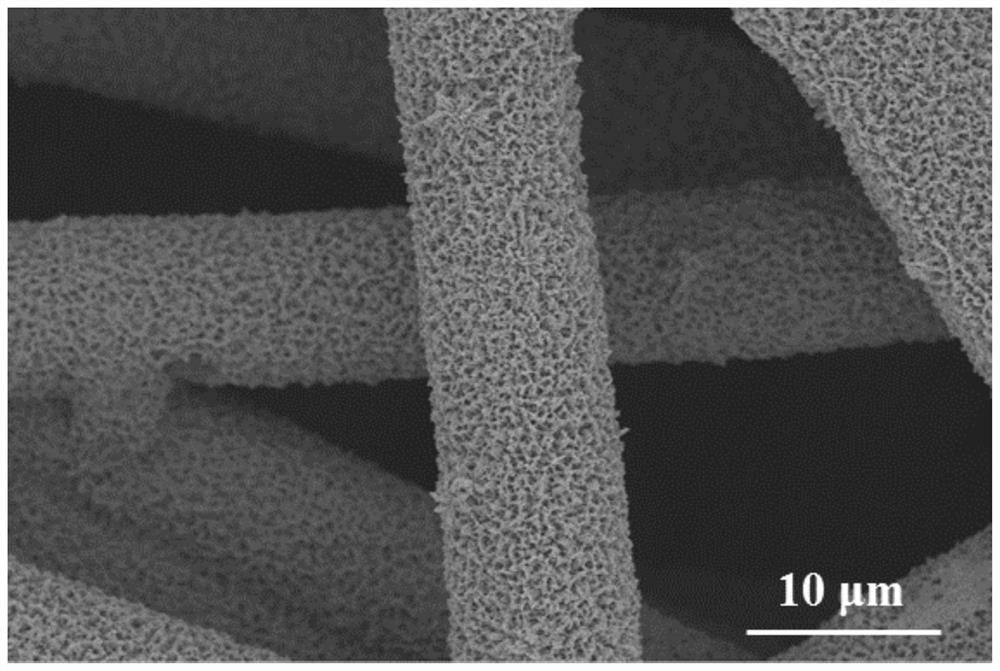

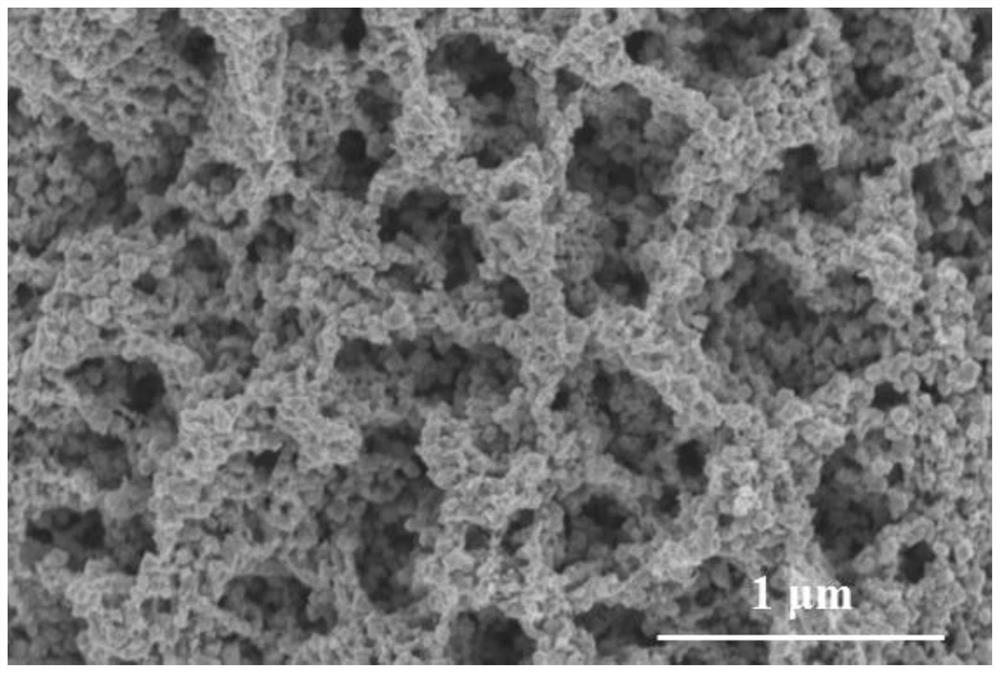

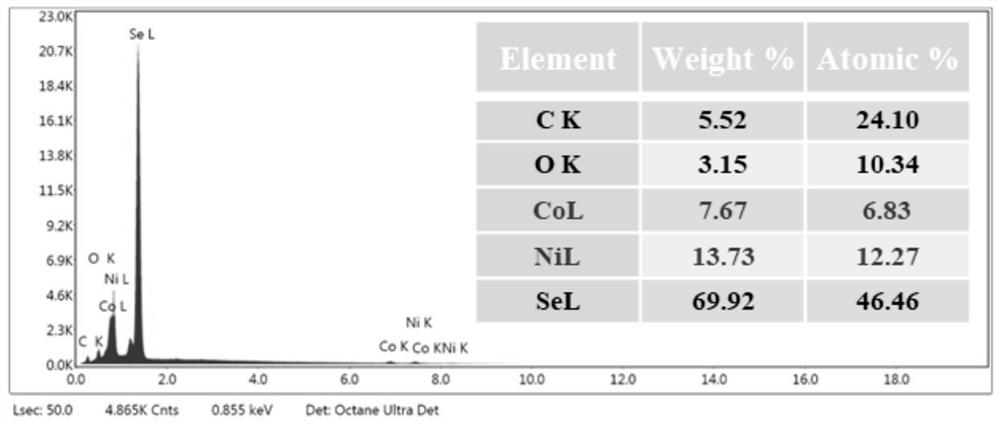

[0041] A NiSe with micro-nano dual-level pores and high structural stability 2 -CoSe 2 The preparation method of / CFs composite material, comprises the following steps:

[0042] Step 1, the porous carbon fiber, 0.3g Ni(NO 3 ) 2 , 0.15g CoSO 4 , 0.1g urea and 30mL deionized water were mechanically stirred and mixed evenly to obtain a precursor solution; the precursor solution was hydrothermally grown in a 50mL autoclave, the hydrothermal growth temperature was 120°C, and the reaction time was 8h to obtain a carbon fiber supported The basic nickel-cobalt carbonate nanowire primary product; the carbon fiber-loaded basic nickel-cobalt carbonate nanowire primary product is cleaned, that is, it is washed with acetone, ethanol, and deionized water in sequence, and then placed in a vacuum oven at 70 ° C. Dry at a temperature of 12 hours to obtain a carbon fiber-loaded basic nickel-cobalt carbonate nanowire precursor; wherein, the carbon fiber-loaded basic nickel-cobalt carbonate na...

Embodiment 2

[0047] A NiSe with micro-nano dual-level pores and high structural stability 2 -CoSe 2 The preparation method of / CFs composite material, comprises the following steps:

[0048] Step 1, the porous carbon fiber, 0.4g Ni(NO 3 ) 2 , 0.2g Co(NO 3 ) 2 , 0.1g urea and 35mL deionized water were mechanically stirred and mixed evenly to obtain a precursor solution; the precursor solution was hydrothermally grown in a 50mL autoclave, the hydrothermal growth temperature was 130°C, and the reaction time was 10h to obtain a carbon fiber loaded The basic nickel-cobalt carbonate nanowire primary product; the carbon fiber-loaded basic nickel-cobalt carbonate nanowire primary product is cleaned, that is, it is washed with acetone, ethanol, and deionized water in sequence, and then placed in a vacuum oven at 70 ° C. Dry at a temperature of 12 hours to obtain a carbon fiber-loaded basic nickel-cobalt carbonate nanowire precursor;

[0049] Among them, the atomic ratio of Ni and Co in the car...

Embodiment 3

[0054] A NiSe with micro-nano dual-level pores and high structural stability 2 -CoSe 2 The preparation method of / CFs composite material, comprises the following steps:

[0055] Step 1, the porous carbon fiber, 0.28gNiSO 4 , 0.15gCo(NO 3 ) 2 , 0.1g urea and 30mL of deionized water were mechanically stirred and mixed evenly to obtain a precursor solution; the precursor solution was hydrothermally grown in a 50mL autoclave, the hydrothermal growth temperature was 120°C, and the reaction time was 10h to obtain a carbon fiber loaded The basic nickel-cobalt carbonate nanowire primary product; the carbon fiber-loaded basic nickel-cobalt carbonate nanowire primary product is cleaned, that is, it is washed with acetone, ethanol, and deionized water in sequence, and then placed in a vacuum oven at 70 ° C. Dry at a temperature of 12 hours to obtain a carbon fiber-loaded basic nickel-cobalt carbonate nanowire precursor;

[0056] Among them, the atomic ratio of Ni and Co in the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com