Mechanical molding fiber reinforce plastic (FRP) electrolytic cell and preparation method thereof

An electrolytic cell and glass fiber reinforced plastic technology, applied in the electrolytic process, electrolytic components, plating tanks, etc., can solve the problems of uneven thickness of the coating layer, poor dipping of the aggregate, affecting the electrolytic output, etc., to achieve accurate size and improve smoothness. , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

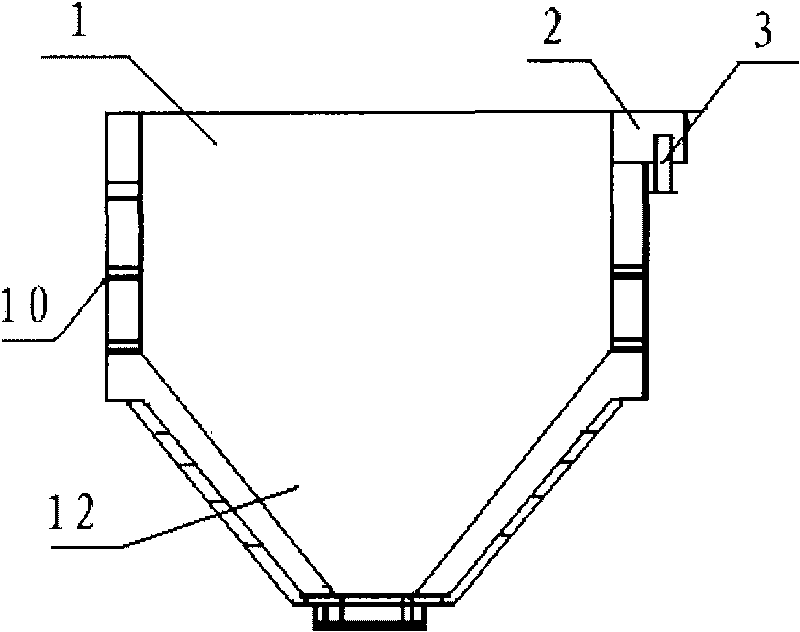

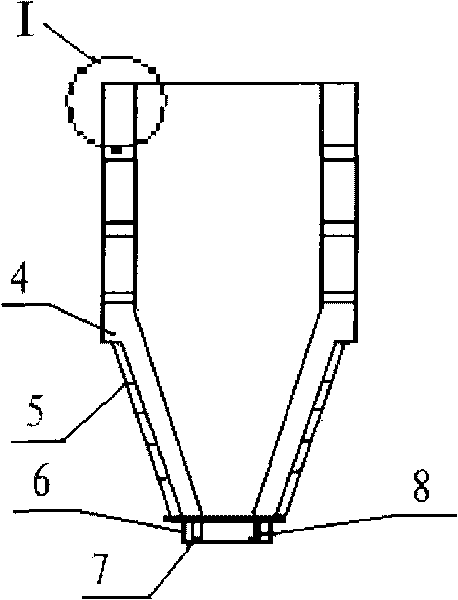

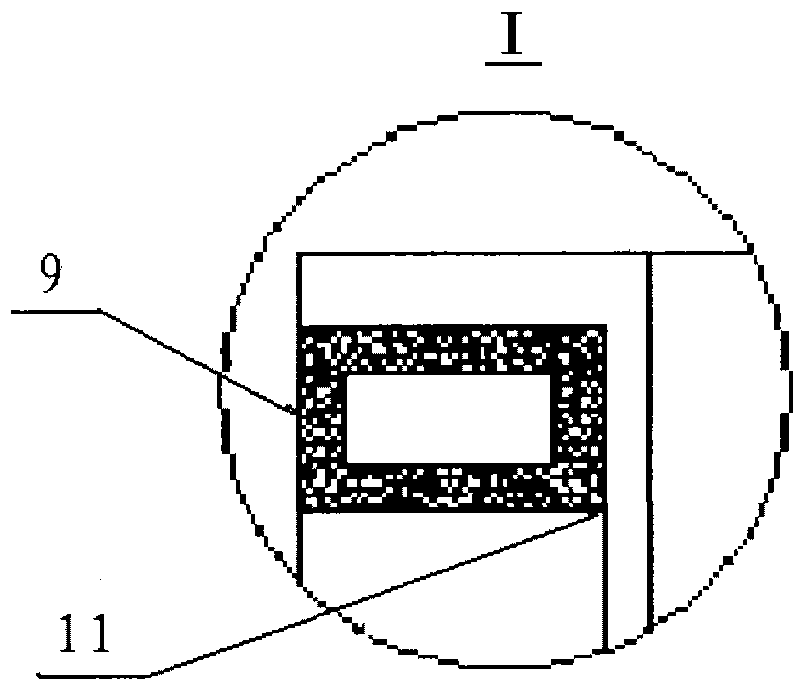

[0036] A mechanically formed FRP electrolytic cell, the FRP electrolytic cell is provided with an overflow tank 2 near the top of the tank, an overflow tank flange 3 is provided at the bottom of the overflow tank 2, and a discharge port 8 is provided at the bottom of the electrolytic cell , the electrolytic cell wall plate 10 is made of glass fiber reinforced resin, the electrolytic cell is composed of four cell wall plates 10, the four cell wall plates 10 are molded in pieces, and each cell wall plate 10 is divided into rectangular parts and Conical part, surrounded by four tank wall plates 10 to divide the electrolytic cell into two parts, the upper part is a rectangular tank 1, the lower part is a tapered tank 12, and the four inner corners and four outer corners of the joints of the tank wall boards 10 The corners are mechanically pressurized, and the inner corners are circular inner corners; grooves 11 are left when the rectangular part of the groove wall plate 10 is molde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com