Light weight gypsum wall body field one piece constrction method

A technology of overall construction and construction method, applied in the direction of walls, building components, buildings, etc., can solve problems such as the leakage of water-soluble gypsum slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

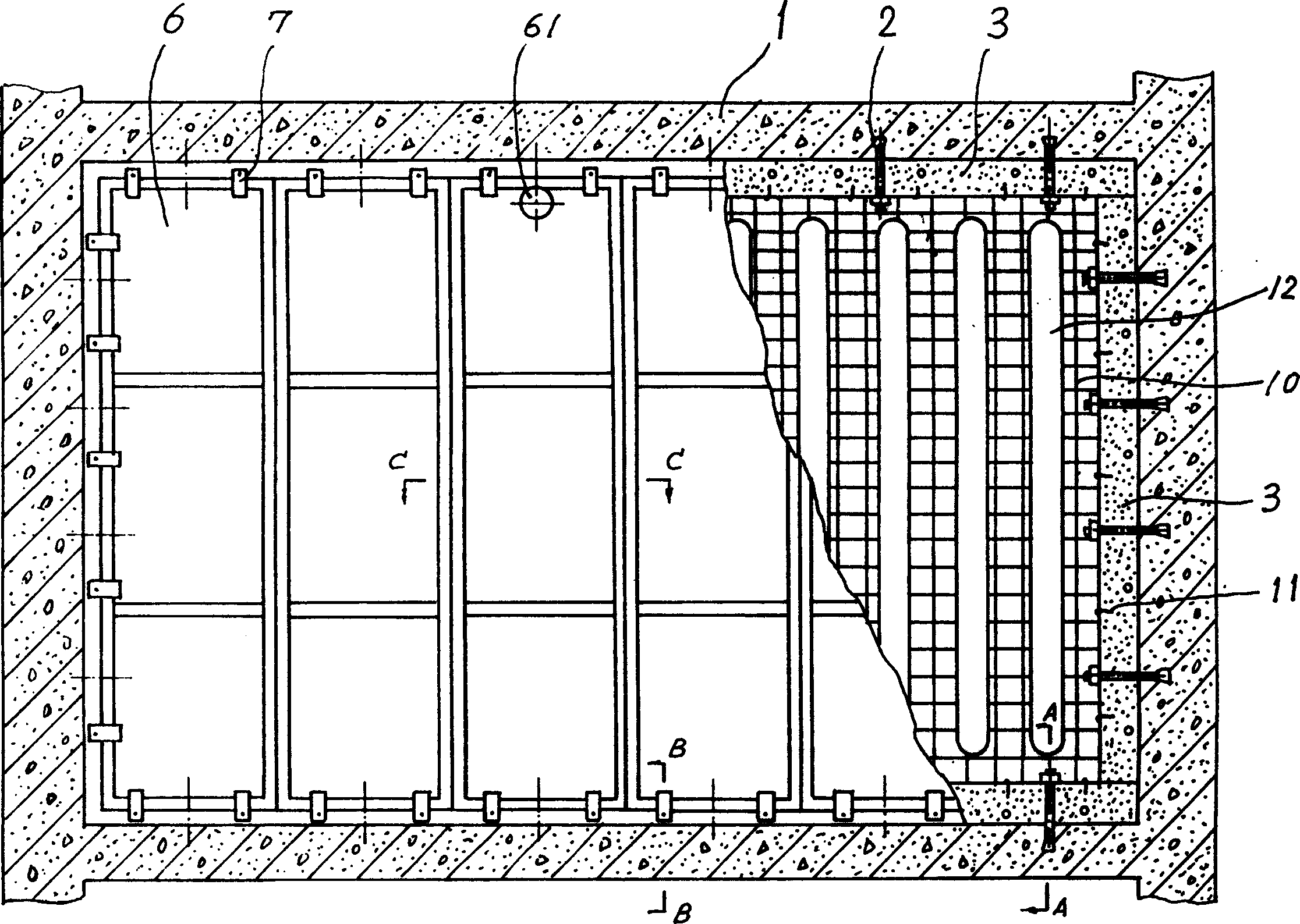

[0021] Reference Figure 1 ~ Figure 4 The construction method of the present invention is as follows:

[0022] (1) A number of expansion bolts 2 are evenly embedded in the concrete frame 1 around the proposed wall.

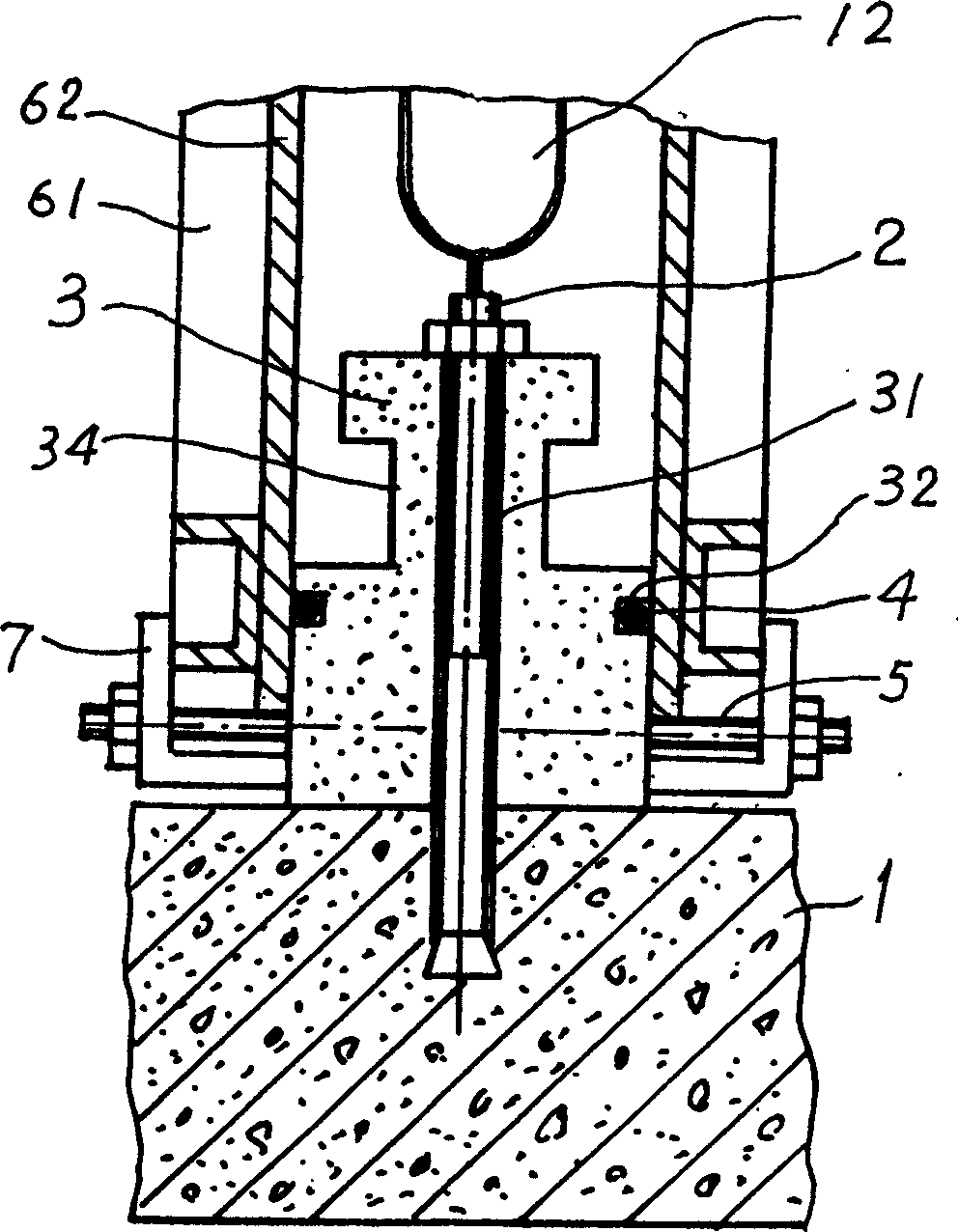

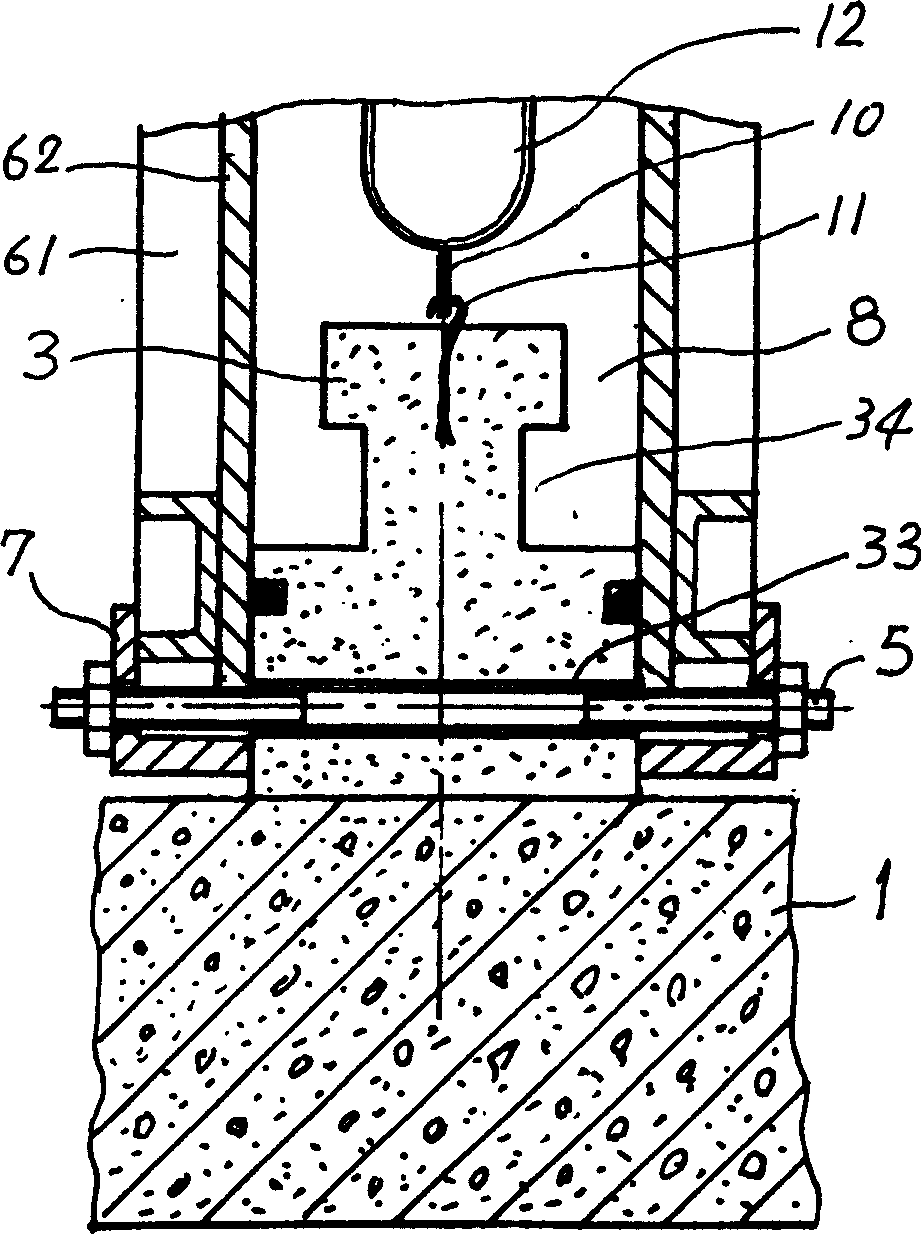

[0023] (2) Four prefabricated cement frames 3 with the same width as the thickness of the proposed wall are fastened to the concrete frame 1 around the proposed wall through their through holes 31 and expansion bolts 2.

[0024] (3) The sealing tape 4 is installed in the longitudinal grooves 32 on both sides of the cement frame 3, and several horizontal through holes 33 are evenly opened on the cement frame 3, and stud bolts 5 are placed in the through holes 33.

[0025] (4) A number of rectangular formwork 6 that are connected together by lap joints are fastened on both sides of the cement frame 3 through a number of L-shaped pressing blocks 7 with bolt through holes, stud bolts 5 and nuts. A pseudo wall cavity 8 is formed, and a double-sided adhesive tape 9 for seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com