Preparation method of lithium battery negative pole piece

A technology for negative pole pieces and lithium batteries, which is applied in the direction of electrode manufacturing, battery electrodes, negative electrodes, etc., can solve the problems of negative pole piece powder dropping, etc., and achieve the effects of short production cycle, wide range of sources and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

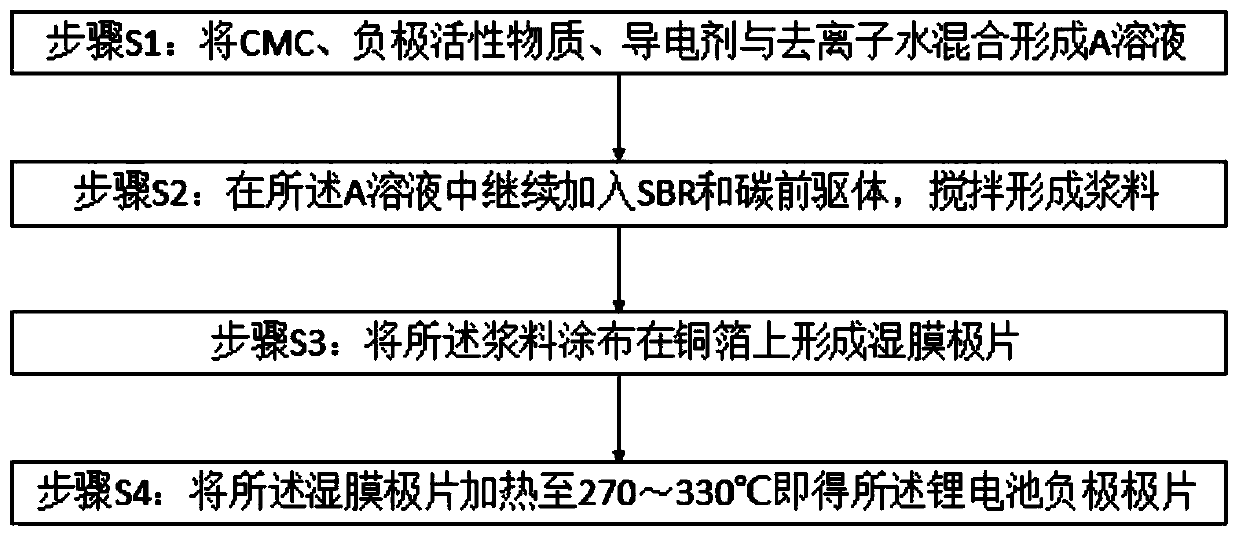

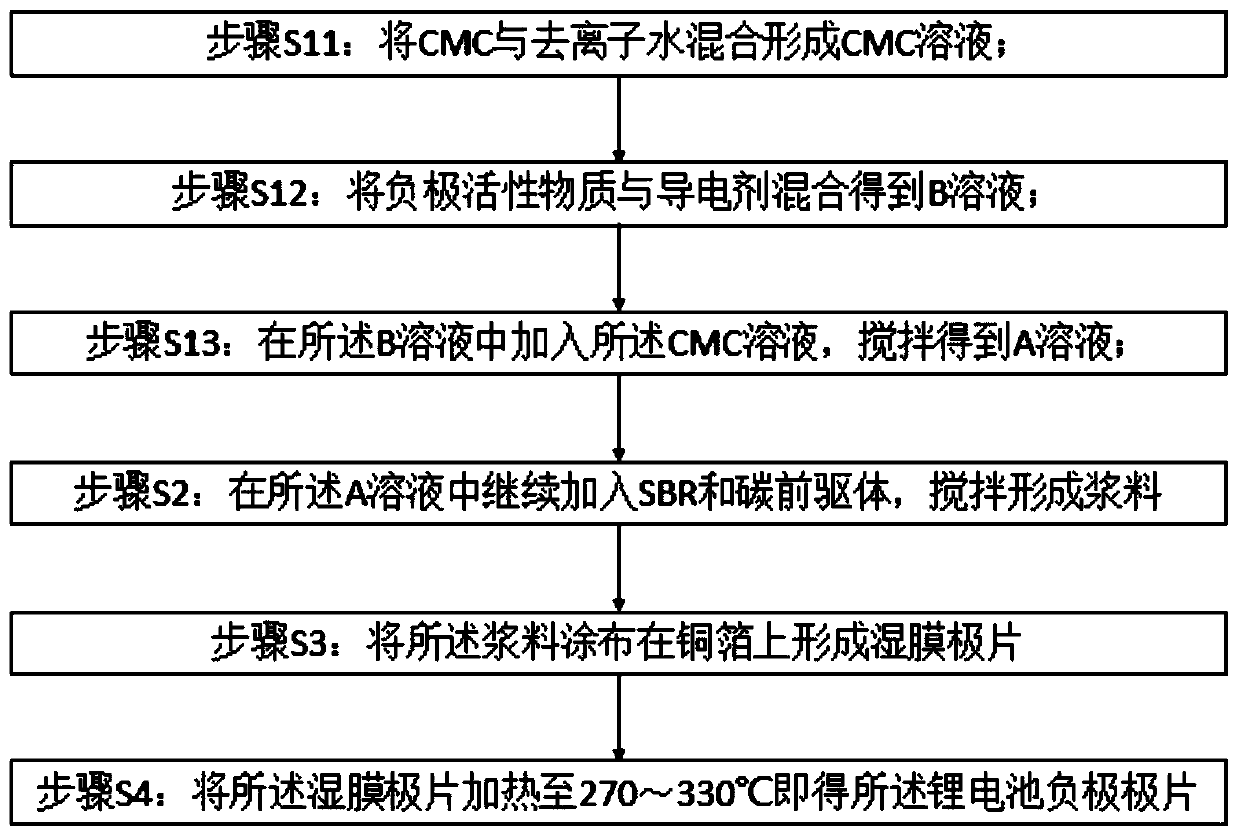

Method used

Image

Examples

Embodiment 1

[0030] Preparation of negative electrode sheet 1:

[0031] Add 100g of silicon carbon, 1g of conductive agent, and 1.3g of CMC dry powder into the mixer, and stir evenly for 40 minutes. In order to improve the mixing effect, add 50g of deionized water in three times, add 30g of deionized water for the first time, and stir evenly for 30 minutes; the second time Add 10g of deionized water, stir evenly for 30 minutes, and make a slurry; finally add 10g of deionized water, stir for 30 minutes, mix well, add 1.3g of SBR (solid content 40%), 1.3g of sucrose, stir evenly for 30min, and the pulping is completed.

[0032] Put the slurry into the slurry buffer tank of the coating machine, evenly coat the two sides of the copper foil to form a wet film pole piece, put it into an oven at a temperature of 300°C, and dry it to obtain the negative pole piece 1 .

Embodiment 2

[0034] Preparation of negative electrode sheet 1:

[0035] Add 98.5g of deionized water to the blender, slowly add 1.5g of sodium carboxymethylcellulose, stir evenly to make a CMC solution, and let it stand for 3 hours for use.

[0036] Add 100g of natural graphite and 1g of conductive agent to another mixer, stir evenly for 30min to form a solution, add 48g of CMC solution, stir evenly for 45min to form a high viscosity state; continue to add the remaining 52g of CMC solution, and stir evenly for 45min. Add 2.25g SBR (40% solid content) and 2.25g sucrose, stir evenly for 30min, and the pulping is completed.

[0037] Put the slurry into the slurry buffer tank of the coating machine, evenly coat the two sides of the copper foil to form a wet film pole piece, put it into an oven at a temperature of 300° C., and dry it to obtain the negative pole piece 2 .

[0038] Compared with the prior art, the lithium battery negative electrode sheet prepared by the present invention reduces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com