Composite porous membrane and preparation method thereof

A porous and porous film technology, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problems of electrochemical performance impact, diaphragm volume change, and low diaphragm utilization, and achieve low surface tension and glass transition temperature Low, the effect of avoiding curling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

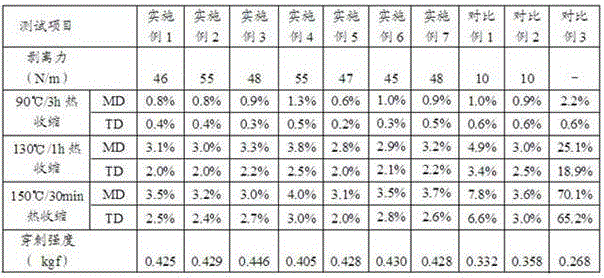

Embodiment 1

[0030] Embodiment 1: This embodiment provides a composite porous diaphragm, including an organic layer and an inorganic coating disposed on the surface of the organic layer, wherein the organic layer is a polyethylene porous film with a thickness of 12 μm (porosity 45%). In terms of weight percentage, the inorganic coating includes 0.66% water-soluble polymer thickener sodium carboxymethyl cellulose, 0.22% water-based dispersant sorbitan monolaurate, and 11% styrene-butadiene rubber emulsion (The glass transition temperature of dry glue is lower than 50°C, and the melting point is higher than 250°C) and 88.12% inorganic alumina powder (median particle size is 1.5um, specific surface is 4m2 / g), the solubility parameter of styrene-butadiene rubber emulsion is 17.6 (J / cm 3 ) 1 / 2 , The surface tension is 44 dynes / cm. The thickness of the inorganic coating is 3 µm, coated on both sides, so the thickness of the entire composite porous separator is 18 µm.

[0031] Using a scanning...

Embodiment 2

[0032] Embodiment 2: This embodiment provides a composite porous diaphragm, including an organic layer and an inorganic coating disposed on the surface of the organic layer, wherein the organic layer is a polypropylene porous film with a thickness of 16 μm (50% porosity). In percent by weight, the inorganic coating wherein includes 1% water-soluble polymer thickener carboxyethyl cellulose, 1% water-based dispersant polyoxyethylene dioleate, 2% pure acrylic latex emulsion (the The glass transition temperature of dry glue is lower than 50°C, and the melting point is higher than 250°C) and 96% of inorganic silica powder (median particle size is 0.5um, specific surface is 4m 2 / g), the solubility parameter of pure acrylic latex emulsion is 16.6 (J / cm 3 ) 1 / 2 , surface tension 40 dynes / cm. The thickness of the inorganic coating is 2 µm, and it is coated on both sides, so the thickness of the entire composite porous separator is 20 µm.

Embodiment 3

[0033] Embodiment 3: This embodiment provides a composite porous membrane, including an organic layer and an inorganic coating disposed on the surface of the organic layer, wherein the organic layer is a polypropylene / polyethylene / polypropylene composite porous film with a thickness of 20 μm (porosity 43%). In percent by weight, the inorganic coating wherein includes 0.5% water-soluble polymer thickener polyacrylamide, 0.5% water-based dispersant tetraethylene glycol monostearate, 20% styrene-acrylic latex emulsion (its The glass transition temperature of dry glue is lower than 50°C, and the melting point is higher than 250°C) and 79% of inorganic zirconia powder (median particle size is 0.3um, specific surface is 8m 2 / g), the solubility parameter of styrene-acrylic latex emulsion is 17.8(J / cm 3 ) 1 / 2 , The surface tension is 42 dynes / cm. The thickness of the inorganic coating is 4 µm, and it is coated on one side, thus, the thickness of the entire composite porous separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com