Heat preservation and sound absorption paste for roof and preparation method of heat preservation and sound absorption paste

A paste and sound-absorbing technology, which is applied in the field of thermal insulation and sound-absorbing spray paste and its preparation on the roof, can solve the problems that cannot meet the requirements of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

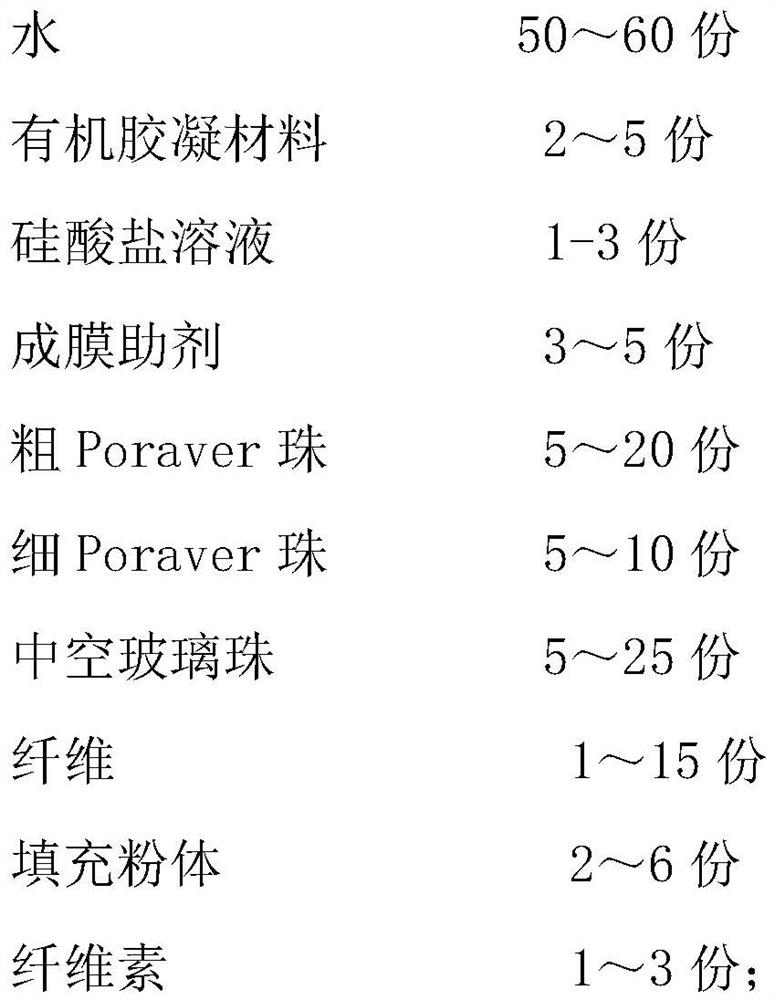

[0038] A heat-insulating and sound-absorbing paste for roofs is prepared from the following components according to the following ratios in parts by mass:

[0039]

[0040] The preparation method of the heat-insulating and sound-absorbing paste for the roof of the present embodiment comprises the following steps:

[0041] 1) Add water to the reaction kettle, then add organic gelling material, fiber, silicate solution and additives, disperse and stir at 500r / min for 10min;

[0042] 2) Pre-mix coarse Poraver beads, fine Poraver beads, hollow glass beads, filling powder and additives until no obvious powder accumulation is formed into mixed powder;

[0043] 3) Then pour the mixed powder prepared in step 2) into the liquid material prepared in step 1) at a stirring rate of 40r / min at a constant speed;

[0044] 4) Finally, stir at 60 r / min for 15 minutes to prepare the heat-insulating and sound-absorbing paste for the roof.

[0045] The bulk density of the thick Poraver beads ...

Embodiment 2

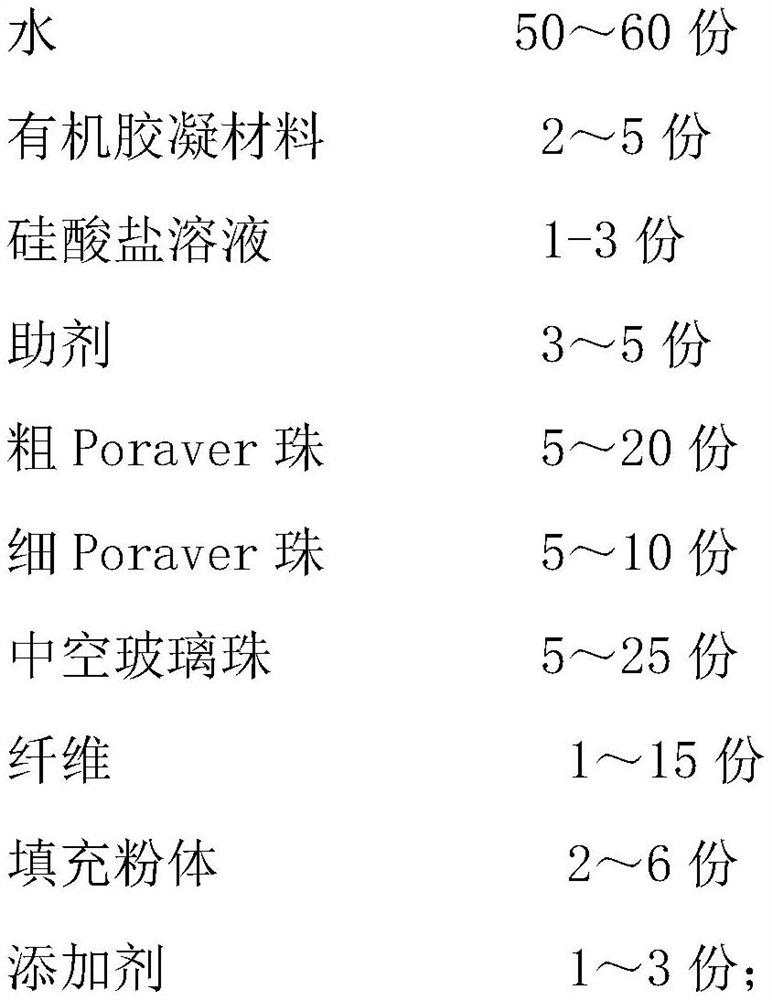

[0058] A heat-insulating and sound-absorbing paste for roofs is prepared from the following components according to the following ratios in parts by mass:

[0059]

[0060]

[0061] The preparation method of the heat-insulating and sound-absorbing paste for the roof of the present embodiment comprises the following steps:

[0062] 1) Add water to the reaction kettle, then add organic gelling material, fiber, silicate solution and additives, disperse and stir at 700r / min for 5min;

[0063] 2) Pre-mix coarse Poraver beads, fine Poraver beads, hollow glass beads, filling powder and additives until no obvious powder accumulation is formed into mixed powder;

[0064] 3) Then pour the mixed powder prepared in step 2) into the liquid material prepared in step 1) at a stirring rate of 100r / min;

[0065] 4) Finally, stir at 120r / min for 10min to prepare the heat-insulating and sound-absorbing paste for the roof.

[0066] The bulk density of the thick Poraver beads is 110~150kg / ...

Embodiment 3

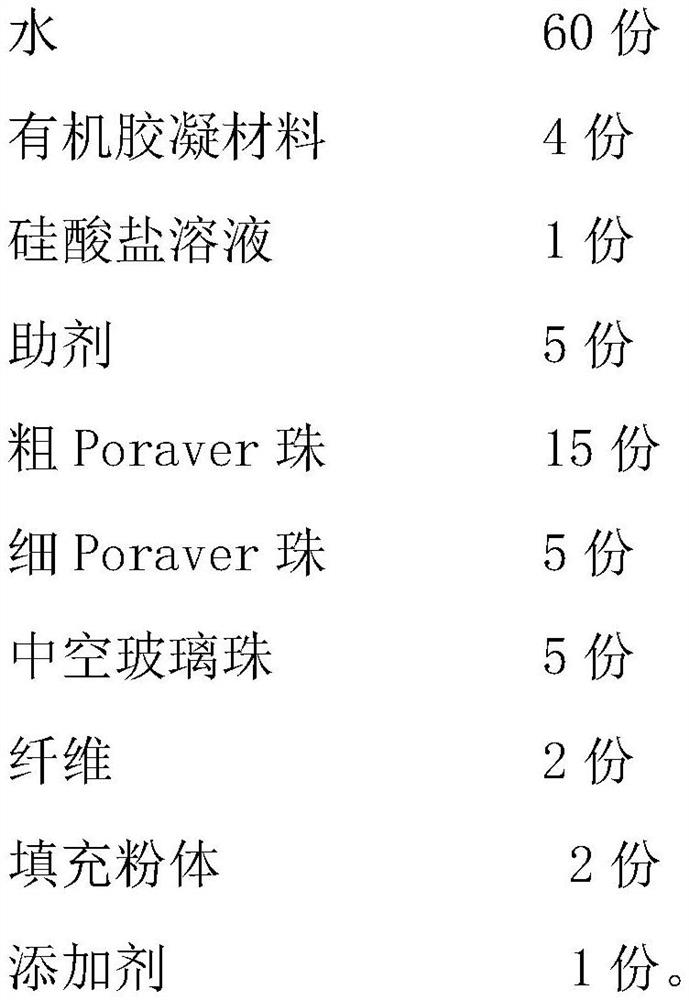

[0078] A heat-insulating and sound-absorbing paste for roofs is prepared from the following components according to the following ratios in parts by mass:

[0079]

[0080] The preparation method of the heat-insulating and sound-absorbing paste for the roof of the present embodiment comprises the following steps:

[0081] 1) Add water to the reaction kettle, then add organic gelling material, fiber, silicate solution and additives, disperse and stir at (600) r / min for 6 minutes;

[0082] 2) Pre-mix coarse Poraver beads, fine Poraver beads, hollow glass beads, filling powder and additives until no obvious powder accumulation is formed into mixed powder;

[0083] 3) Then pour the mixed powder prepared in step 2) into the liquid material prepared in step 1) at a stirring rate of 60r / min at a constant speed;

[0084] 4) Finally, stir at (100) r / min for 10-15 minutes to prepare the heat-insulating and sound-absorbing paste for the roof.

[0085] The bulk density of the thick P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com