PC/ABS composite material of metal texture and preparation method thereof

A composite material and metal texture technology, applied in the field of metal texture PC/ABS composite material and its preparation, can solve the problems of its own performance limitation, harm to the environment and health, abnormal smell, etc., to avoid changes in material properties, avoid The effect of greatly increasing the hygroscopicity and reducing the natural escape rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

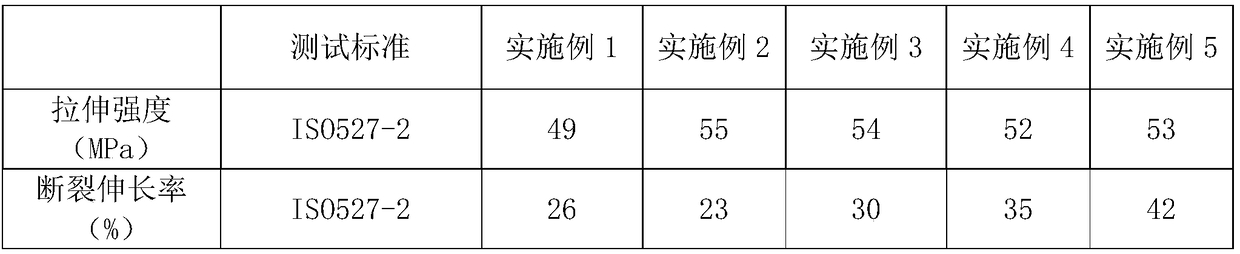

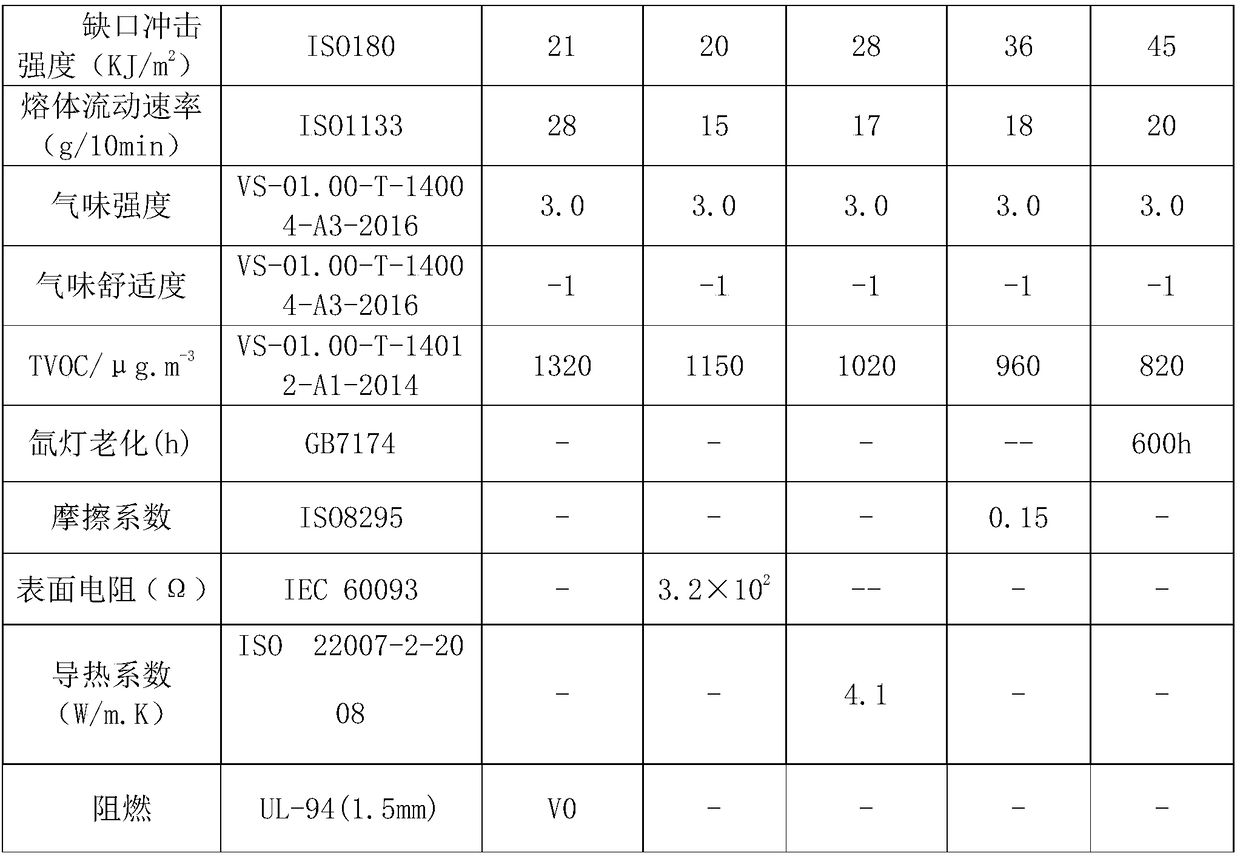

Embodiment 1

[0017] The metal texture PC / ABS composite material of the present embodiment, the composite material raw material comprises the following components by weight: 33 parts of PC, 33 parts of ABS resin, 22 parts of flame retardant, 2 parts of glass pearl powder, 1010 parts of antioxidant 0.3 parts, 0.3 parts of antioxidant 168, 2.0 parts of polyol wax, 0.1 parts of silicone oil, 1.5 parts of extractant, 5 parts of aluminum powder, 0.5 parts of adsorbent; the preparation method is: PC, ABS resin, flame retardant, Glass pearl powder, antioxidant 1010, antioxidant 168, polyol wax, and silicone oil are mixed and put into the feeding barrel of the twin-screw extruder. The temperature of the feeding barrel is controlled to be 50°C, and the screw speed is 350rpm / min , and then enter the extraction and melting zone of the barrel and add the extractant for heating and melting treatment. The temperature of D1 in the extraction and melting zone is 180°C, the temperature of D2 is 190°C, the te...

Embodiment 2

[0019] The metal texture PC / ABS composite material of the present embodiment, the composite material raw material comprises the following components by weight:

[0020] 37 parts of PC, 37 parts of ABS resin, 16 parts of conductive agent, 1.5 parts of glass pearl powder, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, 1.5 parts of polyol wax, 0.08 parts of silicone oil, 1 part of extractant, aluminum powder 4 parts and 1.0 part of adsorbent; its preparation method is: after mixing PC, ABS resin, glass pearl powder, antioxidant 1010, antioxidant 168, polyol wax and silicone oil, it is put into the feeding material of twin-screw extruder barrel, control the temperature of the feeding barrel to 50°C, and the screw speed to 420rpm / min, then enter the extraction and melting zone of the barrel and add extraction agent for heating and melting treatment, the temperature of D1 in the extraction and melting zone is 180°C, and the temperature of D2 is 190°C , the temperature ...

Embodiment 3

[0022] The metal texture PC / ABS composite material of the present embodiment, the composite material raw material comprises the following components by weight:

[0023] The metal texture PC / ABS composite material of this embodiment, the composite material raw material comprises the following components by weight: 40 parts of PC, 40 parts of ABS resin, 12 parts of heat conducting agent, 1 part of glass pearl powder, antioxidant 1010 0.4 0.4 part of antioxidant 168, 1 part of polyol wax, 0.06 part of silicone oil, 1 part of extractant, 3 parts of aluminum powder, 0.5 part of adsorbent; the preparation method is: PC, ABS resin, flame retardant, glass Pearlescent powder, antioxidant 1010, antioxidant 168, polyol wax, and silicone oil are mixed and put into the feeding barrel of the twin-screw extruder. The temperature of the feeding barrel is controlled to be 60°C, and the screw speed is 380rpm / min. Then enter the extraction and melting zone of the barrel and add the extractant fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com