Communication optical cable water-blocking material and preparation method thereof

A communication optical cable and water-blocking technology, which is applied in the field of communication optical cable water-blocking materials and its preparation, can solve the problems of lack of protective flame-retardant performance, unsatisfactory waterproof effect, and falling off of water-blocking powder, so as to achieve good waterproof effect and improve use safety Sexuality, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

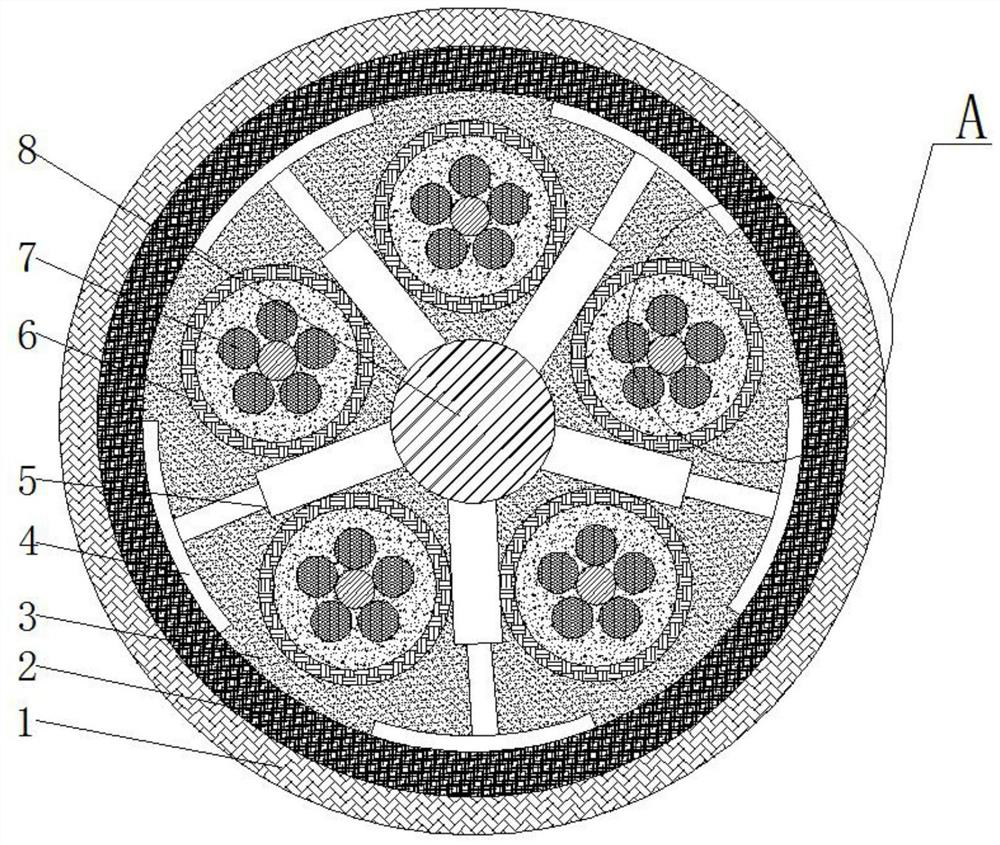

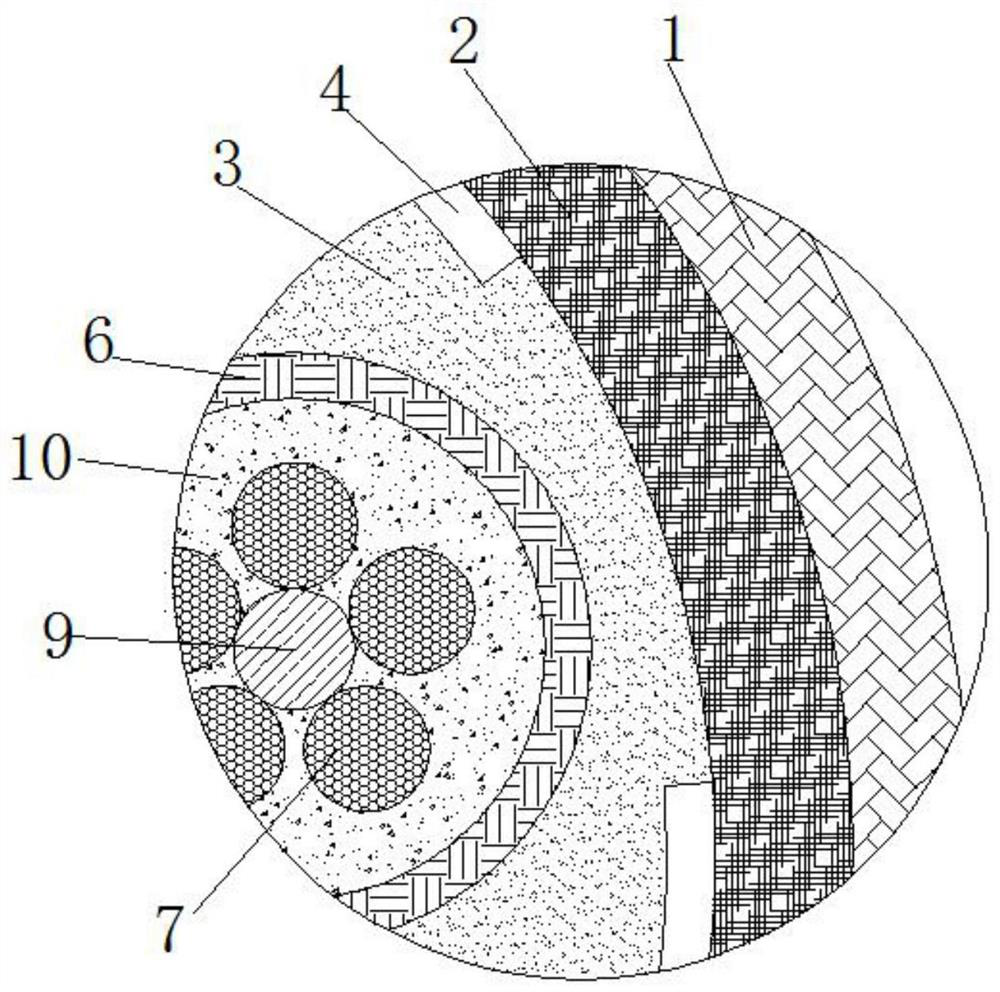

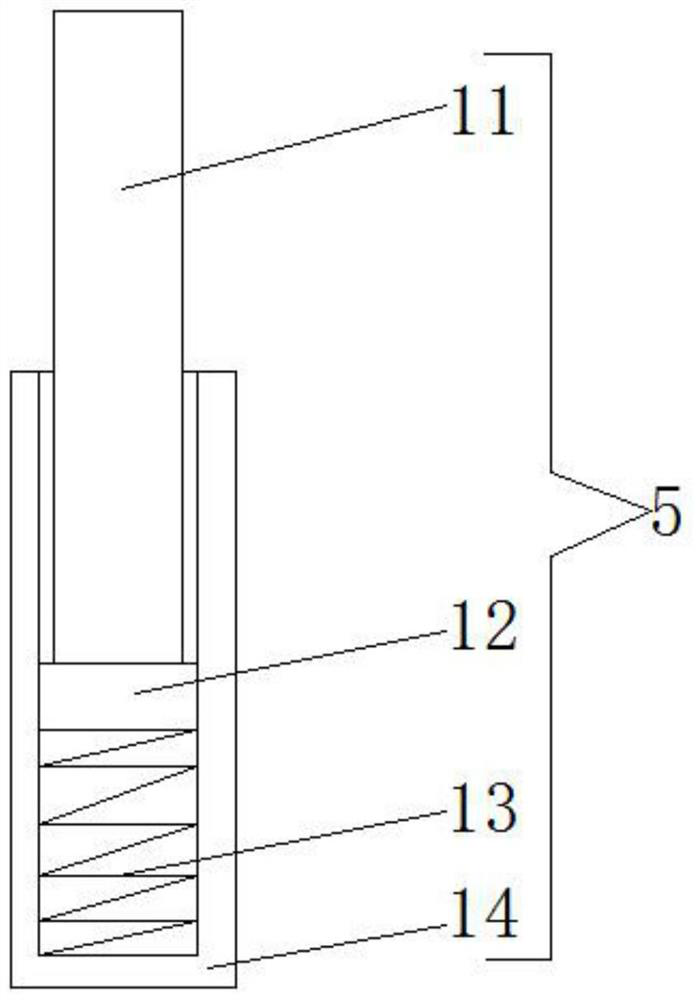

[0046] A water-blocking material for a communication optical cable and a preparation method thereof, comprising a plastic film, the interior of the plastic film is wrapped with a waterproof cloth, the outer surface of the waterproof cloth is bonded with a non-woven fabric, and the outer surface of the non-woven fabric is coated with There is waterproof paint, and fireproof asbestos is filled between the waterproof cloth and the plastic film.

[0047] Further, the waterproof coating includes the following raw materials in parts by weight: 50 parts of absolute ethanol, 6 parts of antioxidant, 15 parts of tung oil, 21 parts of polyurethane emulsion, 3 parts of binder, 12 parts of dispersant, two 2 parts of silicon oxide and 20 parts of polyvinyl aldehyde glue.

[0048] Further, the waterproof coating includes the following preparation methods:

[0049] (1) Select appropriate amount of raw materials according to work requirements;

[0050] (2) Add absolute ethanol and polyvinyl ...

Embodiment 2

[0063] It includes a plastic film, the inside of the plastic film is wrapped with a waterproof cloth, the outer surface of the waterproof cloth is bonded with a non-woven fabric, the outer surface of the non-woven fabric is coated with a waterproof paint, the waterproof cloth and the plastic Fireproof asbestos is filled between the films.

[0064] Further, the waterproof coating includes the following raw materials in parts by weight: 65 parts of absolute ethanol, 7 parts of antioxidant, 20 parts of tung oil, 23 parts of polyurethane emulsion, 4 parts of binder, 13 parts of dispersant, two 3 parts of silicon oxide and 30 parts of polyvinyl aldehyde glue.

[0065] Further, the waterproof coating includes the following preparation methods:

[0066] (1) Select appropriate amount of raw materials according to work requirements;

[0067] (2) Add absolute ethanol and polyvinyl alcohol into the mixer and stir for 20 minutes at a temperature of 80°C to obtain base liquid A;

[0068...

Embodiment 3

[0080] It includes a plastic film, the inside of the plastic film is wrapped with a waterproof cloth, the outer surface of the waterproof cloth is bonded with a non-woven fabric, the outer surface of the non-woven fabric is coated with a waterproof paint, the waterproof cloth and the plastic Fireproof asbestos is filled between the films.

[0081] Further, the waterproof coating includes the following raw materials in parts by weight: 80 parts of absolute ethanol, 8 parts of antioxidant, 25 parts of tung oil, 25 parts of polyurethane emulsion, 5 parts of binder, 14 parts of dispersant, 4 parts of silicon oxide and 40 parts of polyvinyl aldehyde glue.

[0082] Further, the waterproof coating includes the following preparation methods:

[0083] (1) Select appropriate amount of raw materials according to work requirements;

[0084] (2) Add absolute ethanol and polyvinyl alcohol into the mixer and stir for 25 minutes at a temperature of 80°C to obtain base liquid A;

[0085] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com