Antistatic polystyrene polymer composite material and preparation method thereof

A technology of polystyrene and composite materials, applied in the field of polymer materials, can solve the problems of non-permanence, affecting material properties, polluting the surrounding environment, etc., and achieves easy processing and molding, good gloss, good mechanical properties and dimensions The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

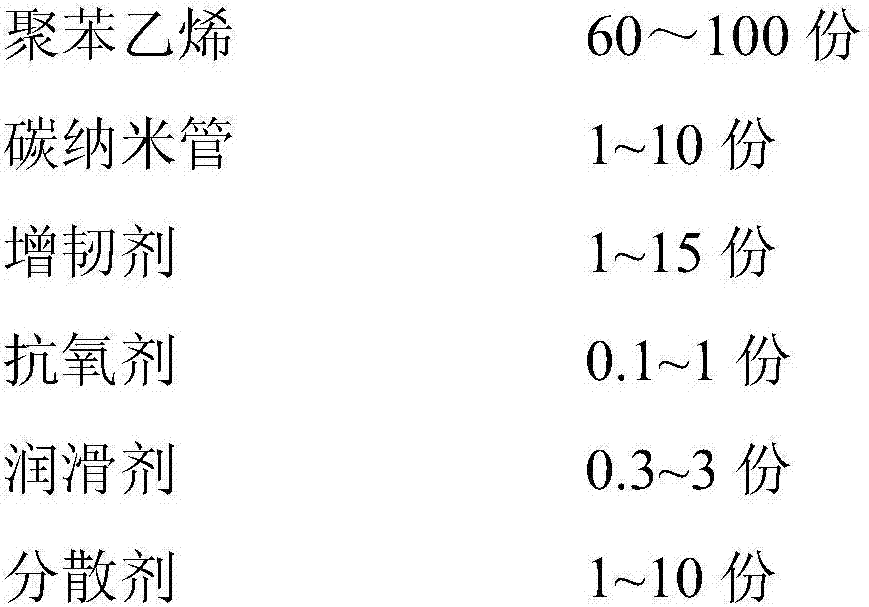

Method used

Image

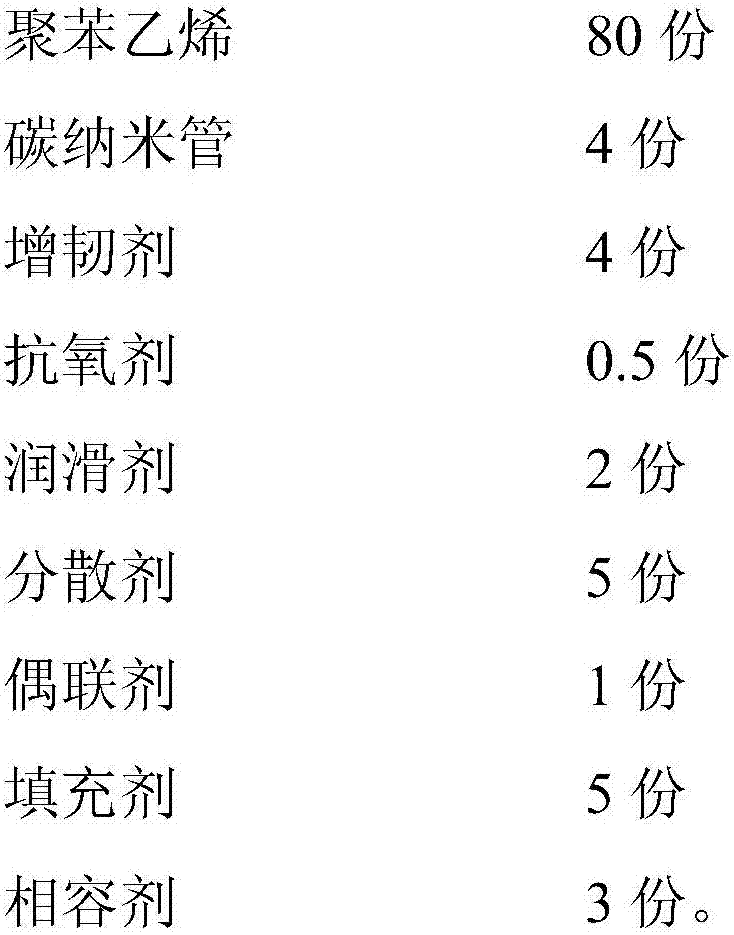

Examples

Embodiment 1

[0032] 1 kg of single-walled carbon nanotubes were placed in a vibrating ball mill with a rotation speed of 1000 rpm and a vibration frequency of 1000 times / min for 5 minutes, and 0.5 kg of powdered multifunctional groups with highly active anchoring groups were added during the grinding process. The mixture of the chelate compound and the polymer containing amine anchoring groups is added at a speed of 150 g / min to reduce the adsorption energy between the carbon nanotubes, thereby reducing the agglomeration between the carbon nanotubes, and then the ground carbon The nanotube is placed in the stirrer that rotating speed is 200 revs / min and stirs for 5 minutes, sprays into the dispersant high molecular weight alkylammonium salt copolymer of 0.25 kilogram of mist liquid state during stirring, and spraying frequency is 50 milliliters / minute, makes The dispersant coats the carbon nanotubes to further reduce the agglomeration of the carbon nanotubes, and the carbon nanotubes unifor...

Embodiment 2

[0037] 2 kilograms of double-walled carbon nanotubes were placed in a vibrating ball mill with a rotation speed of 1500 rpm and a vibration frequency of 1200 times per minute for 8 minutes, and 1 kilogram of powdered multifunctional group with highly active anchoring groups was added during the grinding process. The mixture of the chelate compound and the polymer containing amine anchoring groups is added at a rate of 200 g / min to reduce the adsorption energy between carbon nanotubes, thereby reducing the agglomeration between carbon nanotubes, and then the ground carbon The nanotube is placed in the stirrer that rotating speed is 250 revs / min and stirs for 8 minutes, sprays into the dispersant high molecular weight alkylammonium salt copolymer of 0.5 kilogram of atomized liquid state during stirring, and spraying frequency is 100 milliliters / minute, makes The dispersant coats the carbon nanotubes to further reduce the agglomeration of the carbon nanotubes, and the carbon nanot...

Embodiment 3

[0042] The mixture of 4 kg of single-walled carbon nanotubes, double-walled carbon nanotubes and multi-walled carbon nanotubes was ground for 10 minutes in a vibrating ball mill with a rotating speed of 1800 rpm and a vibration frequency of 1500 times per minute. 3 kg of powdery mixture of polyfunctional chelate with highly active anchoring groups, polymers containing amine anchoring groups and polymers containing acid anchoring groups, the addition speed is 400 g / min to reduce carbon nano Adsorption energy between the tubes, thereby reducing the agglomeration between the carbon nanotubes, and then the ground carbon nanotubes are placed in a mixer with a speed of 300 rpm and stirred for 10 minutes, and 1 kg of mist is sprayed during the stirring process. Liquid dispersant high molecular weight alkyl ammonium salt copolymer, the injection frequency is 150 ml / min, so that the dispersant can coat carbon nanotubes, further reduce the agglomeration between carbon nanotubes, and obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com