A kind of hydrophilic silicon dioxide airgel microsphere and preparation method thereof

A technology of hydrophilic silica and silica, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as industrial production limitations and complicated purification process, and achieve strong pressure bearing capacity and mechanical strength High, simple post-processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing hydrophilic silica airgel microspheres, comprising the following steps:

[0035]1) Synthesis of siloxane prepolymer: Stir tetraalkoxysilane, hydroxyl-containing hydrophilic compound and the first solvent at a speed of 100-1000 rpm until transparent, add dilute acid solution, after the reaction is complete, remove Solvent, obtain siloxane prepolymer; The concentration C of described dilute acid solution H+ =1-6mol / L; the weight ratio of the dilute acid to tetraalkoxysilane is 0.01-0.2:1;

[0036] The first solvent is alcohol, ether or ketone; the hydrophilic compound containing hydroxyl is polyalcohol, monosaccharide or polysaccharide;

[0037] In this step, the alkoxy group of the tetraalkoxysilane is one or more of methoxy, ethoxy and isopropoxy. The hydroxyl-containing hydrophilic compound can be polyethylene glycol with an average molecular weight of 200-10000, polyvinyl alcohol with an average molecular weight of 200-1...

Embodiment 1

[0043] A preparation method for hydrophilic silicon dioxide airgel microspheres, comprising the following steps:

[0044] (1) Mix 278.32 grams of tetraethyl orthosilicate, 150 grams of ethanol, and 10 grams of polyethylene glycol (average molecular weight 1000) until transparent; 15 grams of concentrated hydrochloric acid (mass concentration is 37%) and 20 grams of water are mixed evenly , and then drop it slowly, after the addition is completed, heat up to 60 degrees, continue to stir for 2 hours, and quickly distill off the ethanol in the system under reduced pressure to obtain a fluid, transparent silicone prepolymer with a certain viscosity ;

[0045] (2) Add 50 grams of the above-mentioned siloxane prepolymer to 100 grams of distilled water under high-speed stirring (500 rpm), and after the addition is completed, adjust the pH to 10 with ammonia water, and continue stirring for 2 hours to obtain a white emulsion ;

[0046] (3) Let the above emulsion stand for 1 hour to ...

Embodiment 2

[0049] The difference between embodiment 2 and embodiment 1 is that tetraethyl orthosilicate is replaced by tetramethyl orthosilicate in step (1), and the amount is reduced to 203.5 grams, polyethylene glycol (average molecular weight 1000) Substitute polyvinyl alcohol (average molecular weight 500), reduce the amount to 5 grams, and increase the reaction temperature to 80°C.

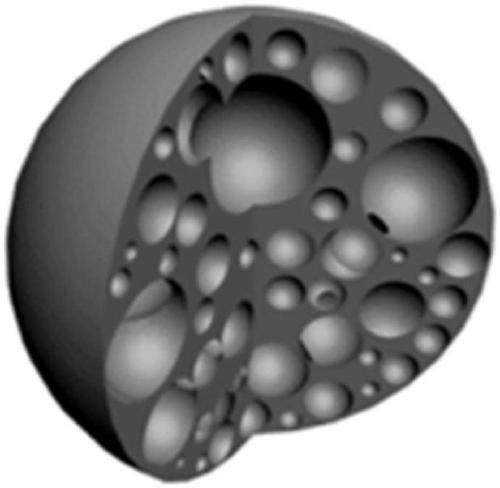

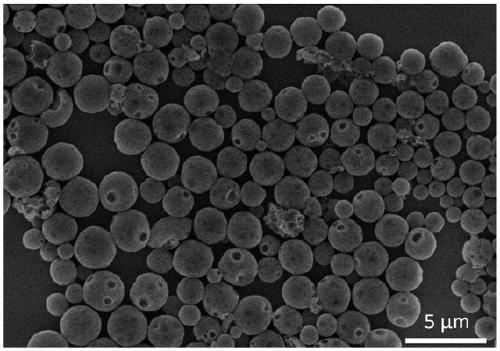

[0050] The transmission electron microscope image of the finally obtained silica airgel is as follows: Figure 5 As shown, its size ranges from 5-10 microns, and its internal porosity is high. After drying, no damage to the porous structure was found under high vacuum conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com