Method for preparing single-phase ZrB2 powder by employing xylitol as carbon source through sol-gel method

A technology of xylitol and gel method, applied in the directions of boron/boride, metal boride, etc., to achieve the effects of simple equipment, low production cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

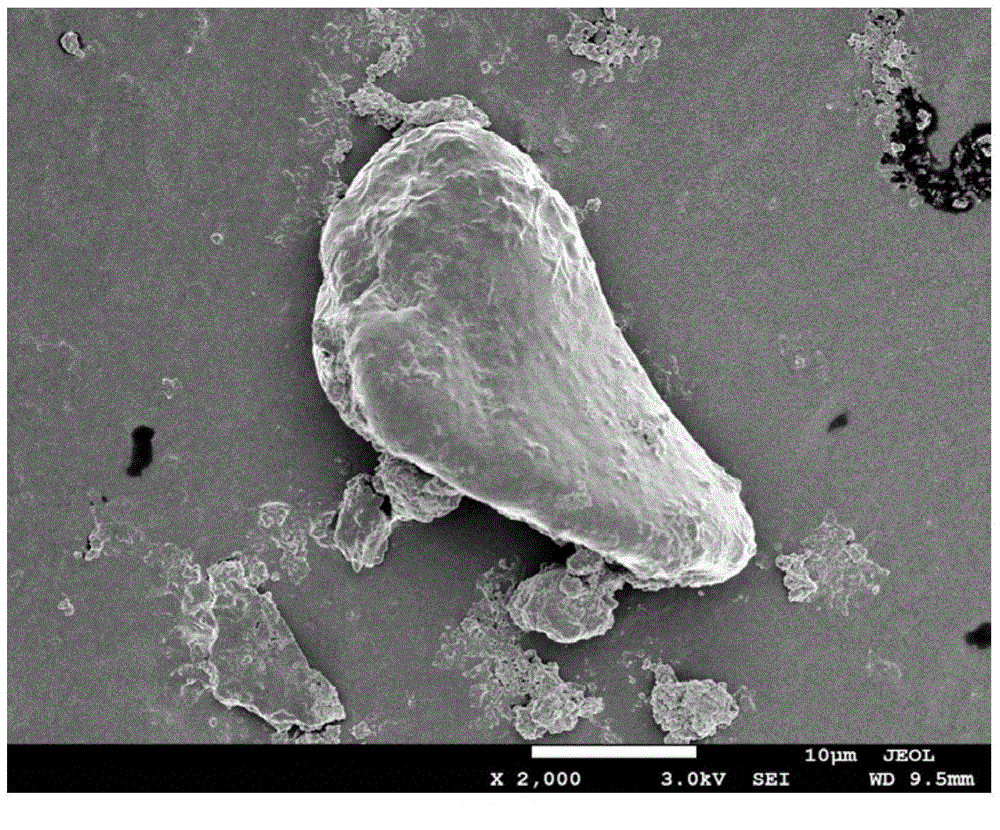

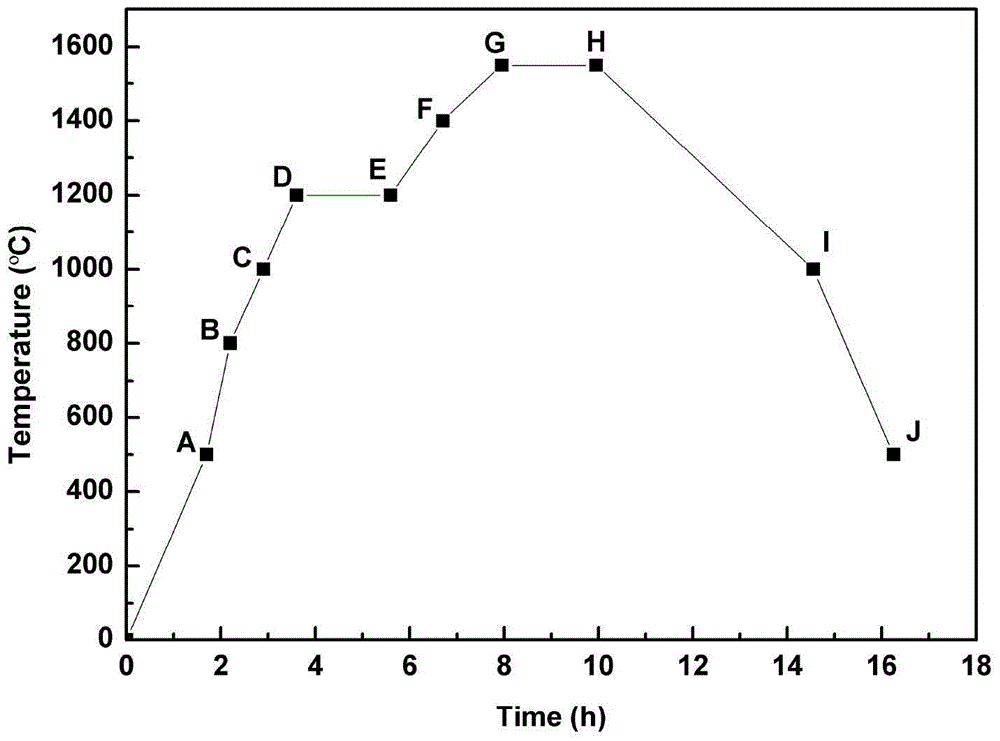

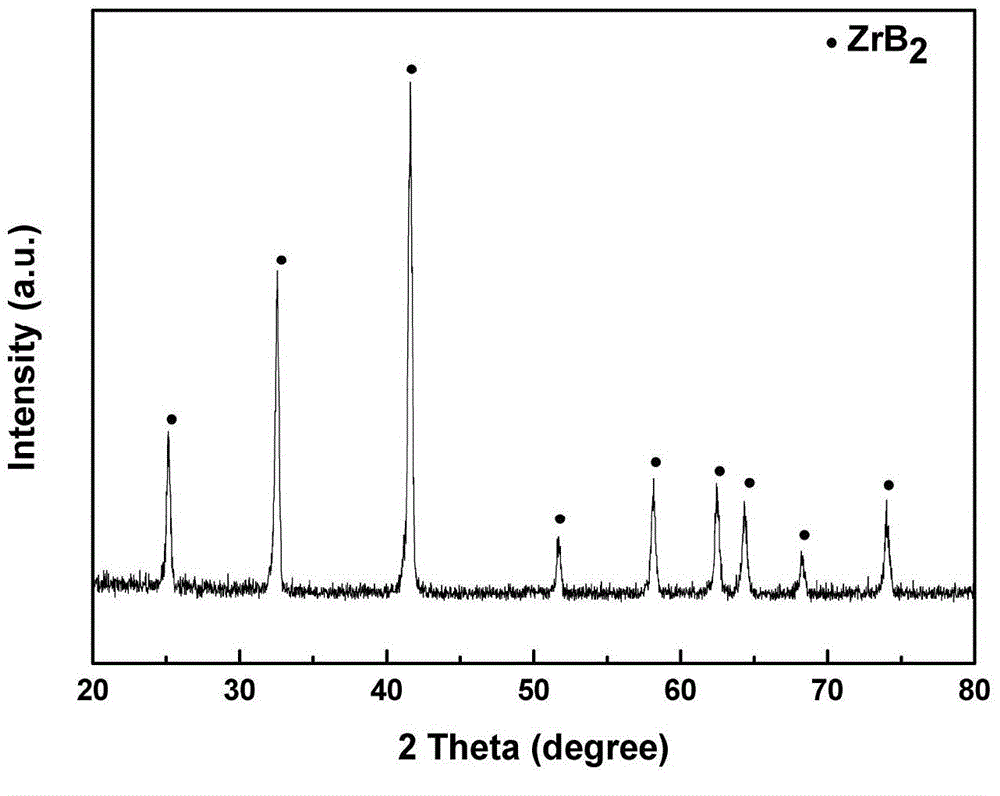

Image

Examples

Embodiment 1

[0054] The present invention provides a method for preparing single-phase ZrB by sol-gel method using xylitol as a carbon source 2 The powder method includes the following steps:

[0055] Step 1: Dissolve xylitol and boric acid in methanol (with a concentration of 99.9% by mass), stir magnetically under a water bath at 60°C until the first solution is formed; the stirring speed is 200r / min;

[0056] Step 2: Mix acetic acid (99% by mass) with zirconium n-propoxide (70% by mass) to form a second solution;

[0057] The mixing conditions are: mixing temperature 20°C, stirring speed 60r / min;

[0058] Step 3: Under the stirring speed of 200r / min, add the second solution to the first solution to form a homogeneous solution;

[0059] Dosage: Add 1.9g boric acid, 4.4g zirconium n-propoxide, 10ml methanol and 10ml acetic acid to 2g xylitol. The stirring adopts the digital display temperature measuring magnetic stirrer produced by Changzhou Huaguan Instrument Manufacturing Co., Ltd.

[0060] Step ...

Embodiment 2

[0067] The present invention provides a method for preparing single-phase ZrB by sol-gel method using xylitol as a carbon source 2 The powder method includes the following steps:

[0068] Step 1: Dissolve xylitol and boric acid in methanol (mass percentage concentration 99.9%), and magnetically stir under 55°C water bath to form the first solution; the stirring speed is 400r / min;

[0069] Step 2: Mix acetic acid (99% by mass) with zirconium n-propoxide (70% by mass) to form a second solution;

[0070] The mixing conditions are: mixing temperature 25°C, stirring speed 120r / min;

[0071] Step 3: Under the stirring speed of 200r / min, add the second solution to the first solution to form a homogeneous solution;

[0072] Dosage: Add 2.6 g of boric acid, 6.2 g of zirconium n-propoxide, 20 ml of methanol, and 20 ml of acetic acid to 2 g of xylitol.

[0073] Step 4: Place the homogeneous solution in a 60℃ water bath for 15 minutes to form a wet gel;

[0074] Step 5: Place the wet gel in a dry env...

Embodiment 3

[0080] The present invention provides a method for preparing single-phase ZrB by sol-gel method using xylitol as a carbon source 2 The powder method includes the following steps:

[0081] Step 1: Dissolve xylitol and boric acid in methanol (mass percentage concentration 99.9%), magnetically stir under 65°C water bath condition to form the first solution; the stirring speed is 300r / min;

[0082] Step 2: Mix acetic acid (99% by mass) and zirconium n-propoxide (70% by mass) to form a second solution; the mixing conditions are: mixing temperature 20°C, stirring speed 80r / min;

[0083] Step 3: Under the stirring speed of 200r / min, add the second solution to the first solution to form a homogeneous solution;

[0084] Dosage: Add 2.2 g of boric acid, 5.2 g of zirconium n-propoxide, 15 ml of methanol, and 15 ml of acetic acid to 2 g of xylitol.

[0085] Step 4: Place the homogeneous solution in a 60°C water bath for 10 minutes to form a wet gel;

[0086] Step 5: Place the wet gel in a dry enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com