Method for preparing light magnesium carbonate

A light magnesium carbonate and magnesium chloride technology, applied in directions such as magnesium carbonate, can solve the problems of complex operation process, low environmental benefit and high production cost, and achieve the effects of simple process, simple production process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

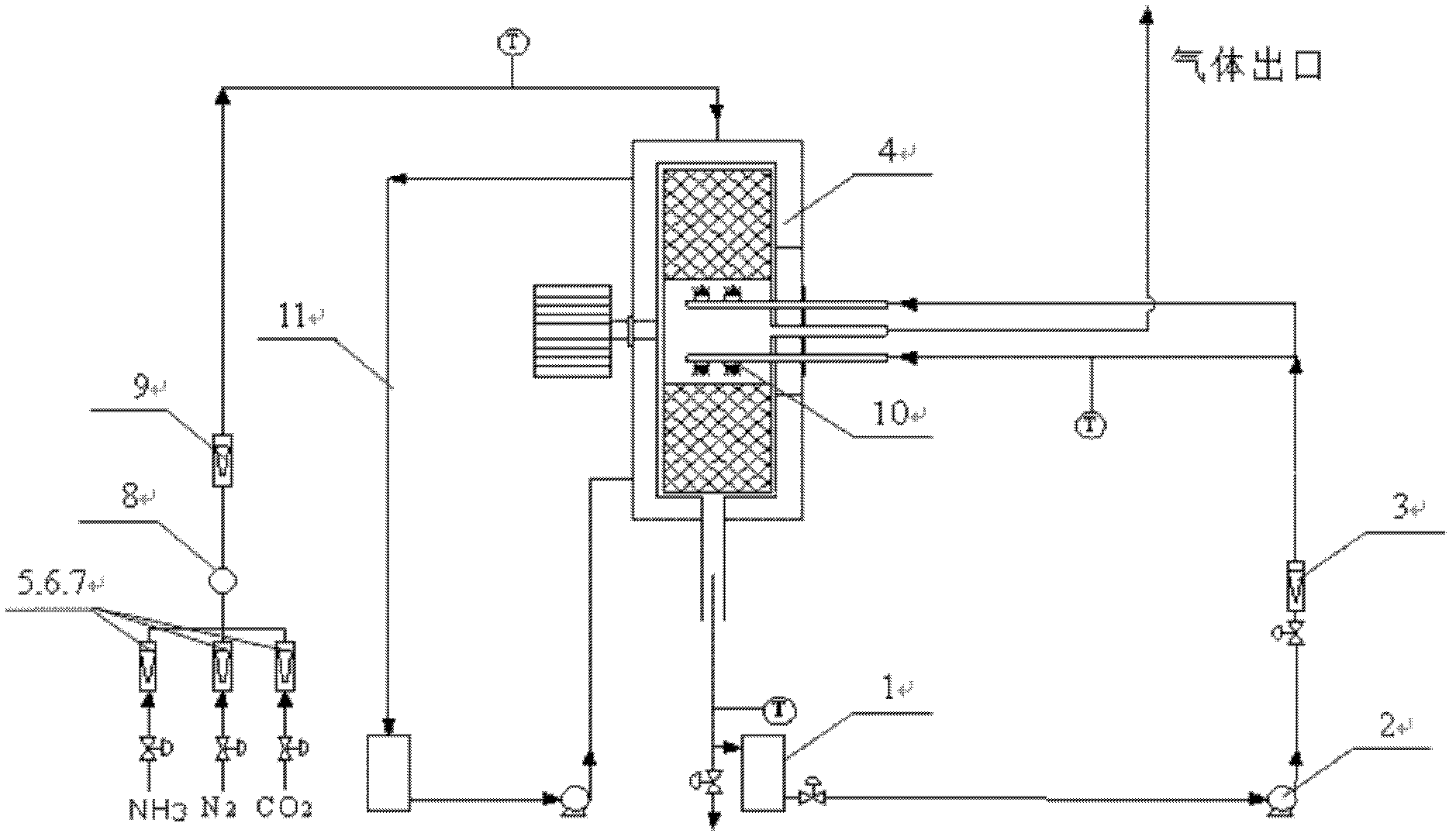

Method used

Image

Examples

Embodiment 1

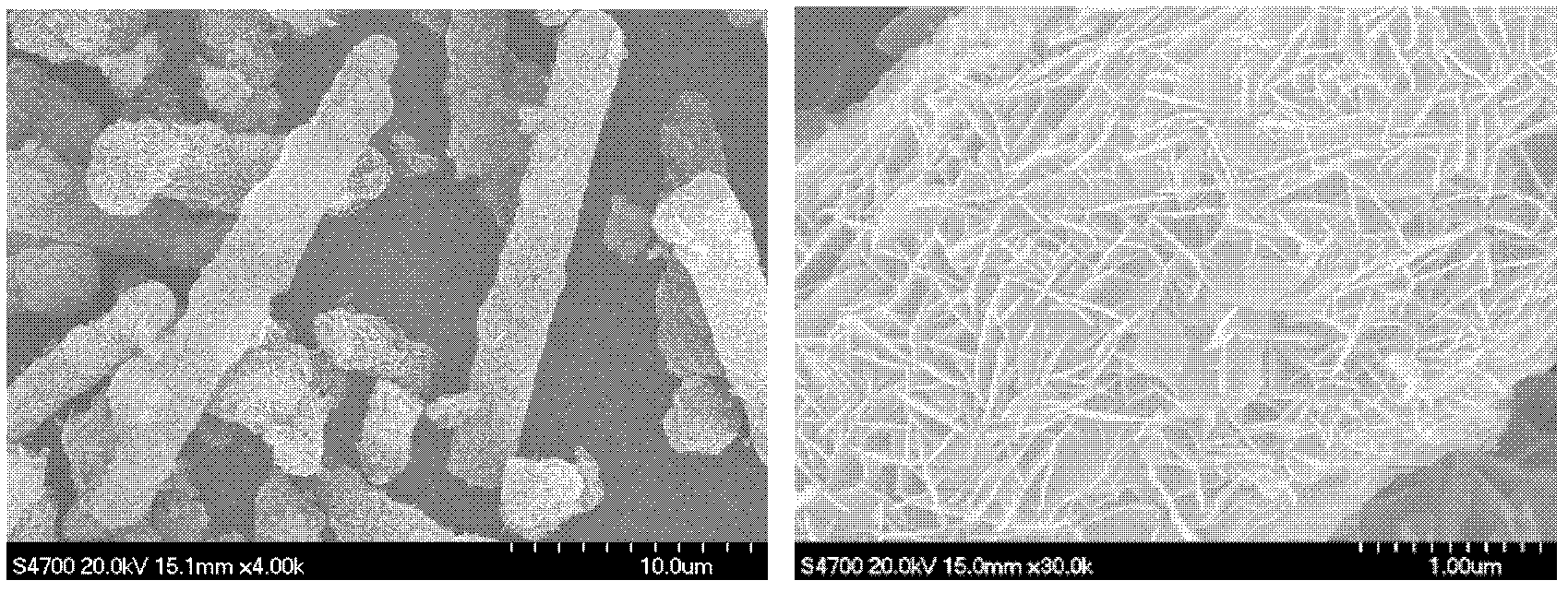

[0083] Prepare 3L of magnesium chloride solution with a concentration of 0.2mol / L, the reaction temperature is 75°C, the liquid flow rate is adjusted to 100L / h, the gas flow rate is 550L / h, NH 3 and CO 2 The volume content is 14% and 7.8% respectively, the operating pressure is one atmosphere, the rotating speed is 600rpm, the outer diameter of the rotor is 10cm, and the inner diameter is 5cm (the supergravity level is 150g), the reaction reaches the end, cooling and filtering, washing with hot deionized water, in 110 ℃ of drying 10h, the product is the rod-shaped light magnesium carbonate (such as figure 2 ), the particle length is 25um, the width is 4um, the thickness of the nanosheet is about 20nm, and the product is 77g, and the yield is 90%.

Embodiment 2

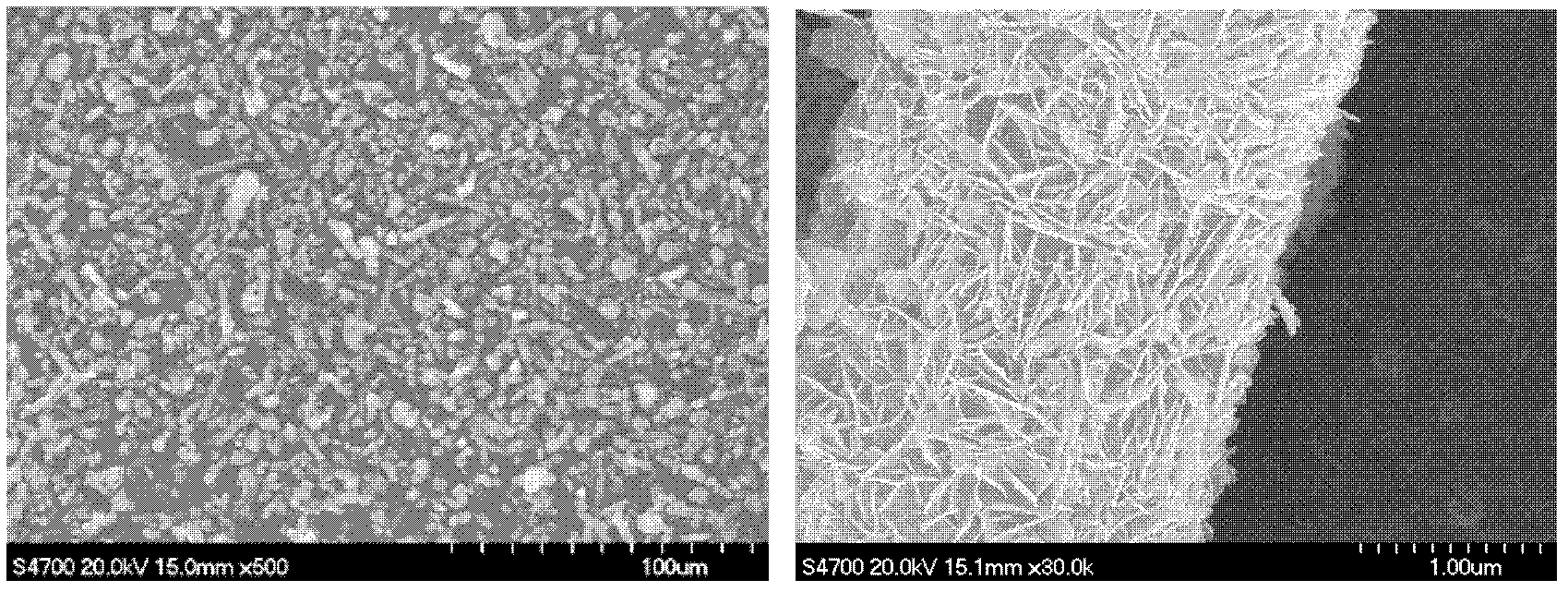

[0085] Prepare 3L of magnesium chloride solution with a concentration of 0.3mol / L, the reaction temperature is 70°C, the liquid flow rate is adjusted to 100L / h, the gas flow rate is 550L / h, NH 3 and CO 2 The volume content is 14% and 7% respectively, the operating pressure is 1 atmosphere, the rotating speed is 800rpm, the outer diameter of the rotor is 10cm, the inner diameter is 5cm (the supergravity level is 266g), the cycle reaction reaches the end, cooling and filtering, washing with hot deionized water, Drying at 110° C. for 10 h, the product is rod-shaped light magnesium carbonate (such as image 3 ), the particle length is 15um, the width is 4um, the thickness of the nanosheet is about 20nm, and the product is 72.8g, and the yield is 85%.

Embodiment 3

[0087] Prepare 3L of magnesium chloride solution with a concentration of 0.4mol / L, the reaction temperature is 76°C, the liquid flow rate is adjusted to 100L / h, the gas flow rate is 550L / h, NH 3 and CO 2 The volume content is 12.6% and 7% respectively, the operating pressure is one atmosphere, the rotating speed is 1000rpm, the outer diameter of the rotor is 10cm, the inner diameter is 5cm (the supergravity level is 416g), the cycle reaction reaches the end point, cooling and filtering, washing with hot deionized water, Drying at 110°C for 10h, the product is a bird's nest light magnesium carbonate with a nanosheet structure (such as Figure 4 ), the average particle size of the particles is 8um, the thickness of the nanosheets is about 20nm, and 74.5g of the product is obtained, with a yield of 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com