Environment-friendly flame-retardant heat-conducting glue and preparation method thereof

A heat-conducting adhesive, environmentally friendly technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of high cost, achieve good mechanical properties, good uniformity, and ensure the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

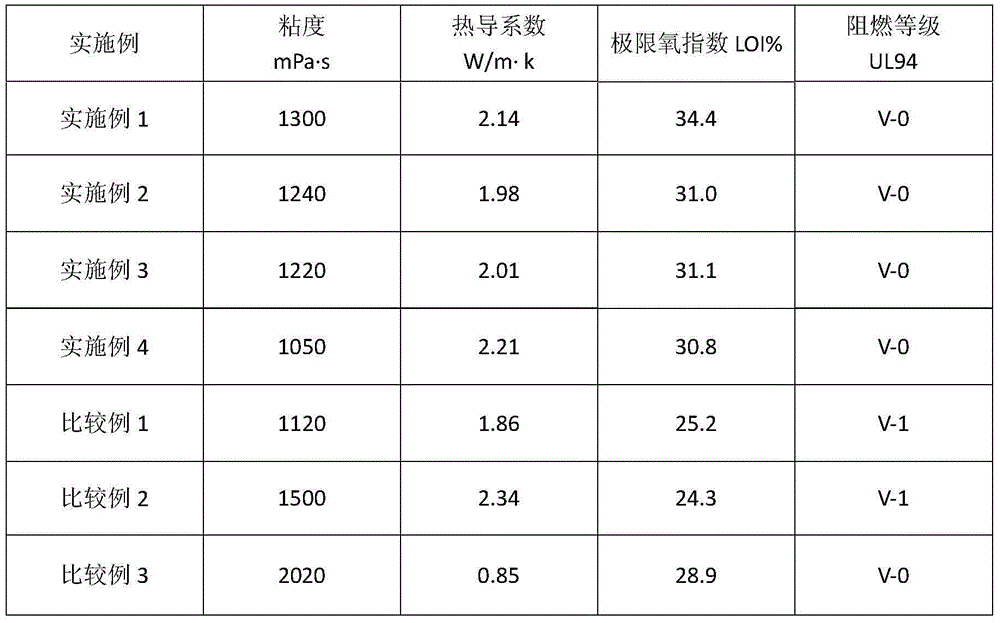

Examples

Embodiment 1

[0036] A method for preparing an environmentally friendly flame-retardant heat-conducting adhesive, comprising the steps of:

[0037] 1) Add 250g of KH-560 to 100L of absolute ethanol solution, slowly add 50g of concentrated ammonia water to adjust the solution to be weakly alkaline (pH value is 7.5), add 12kg of 1μm aluminum nitride, mechanically stir at 60°C for 5h, and rotate at 120r / min. Centrifuge, rinse with absolute ethanol three times, and dry in a vacuum oven at 110°C for 12 hours to obtain component A.

[0038] 2) Send 100kg of epoxy resin E-51, 90kg of methyl hexahydrophthalic anhydride, and 2kg of DMP-30 into a high-speed disperser and mix evenly to obtain low-viscosity component B.

[0039] 3) Mix component A, component B, triphenyl phosphate, and aluminum hydroxide on a three-roll mill in a mass ratio of 50:100:35:15. Under the condition of lower than 60°C, vacuumize for 1h, and the vacuum degree is controlled at 0.05Mpa.

[0040] 4) The mixture after vacuumi...

Embodiment 2

[0042] A method for preparing an environmentally friendly flame-retardant heat-conducting adhesive, comprising the steps of:

[0043] 1) Add 250g KR‐38S to 100L absolute ethanol solution, slowly add 49g concentrated ammonia water to adjust the solution to be weakly alkaline (pH value is 7.3), add 12kg 1μm aluminum nitride, mechanically stir at 60°C for 5h, and rotate at 120r / min. Centrifuge, rinse with absolute ethanol three times, and dry in a vacuum oven at 110°C for 12 hours to obtain component A.

[0044] 2) Send 100kg of epoxy resin E-51, 90kg of methyl hexahydrophthalic anhydride, and 2kg of DMP-30 into a high-speed disperser and mix evenly to obtain low-viscosity component B.

[0045] 3) Mix component A, component B, triphenyl phosphate, and aluminum hydroxide on a three-roll mill in a mass ratio of 50:100:35:15. Under the condition of lower than 60°C, vacuumize for 1h, and the vacuum degree is controlled at 0.05Mpa.

[0046] 4) The mixture after vacuuming is heated...

Embodiment 3

[0048] A method for preparing an environmentally friendly flame-retardant heat-conducting adhesive, comprising the steps of:

[0049] 1) Add 250g KH-560 to 100L absolute ethanol solution, slowly add 51g concentrated ammonia water to adjust the solution to be weakly alkaline (pH value is 8), add 12kg 1μm aluminum nitride, mechanically stir at 60°C for 5h, and rotate at 120r / min. Centrifuge, rinse with absolute ethanol three times, and dry in a vacuum oven at 110°C for 12 hours to obtain component A.

[0050] 2) Send 100kg of epoxy resin E-51, 90kg of methyl hexahydrophthalic anhydride, and 2kg of DMP-30 into a high-speed disperser and mix evenly to obtain low-viscosity component B.

[0051]3) Mix component A, component B, cresyl diphenyl phosphate, and aluminum hydroxide on a three-roll mill in a mass ratio of 50:100:35:15. Under the condition of lower than 60°C, vacuumize for 1h, and the vacuum degree is controlled at 0.05Mpa.

[0052] 4) The mixture after vacuuming is hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com