Organic electroluminescence device and test method thereof

An electroluminescent device and electroluminescent display technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problem of poor contact or poor contact of chip pins, failure to connect chip pins normally, and failure to light up the light-emitting area And other problems, to achieve the effect of increasing width, high yield and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

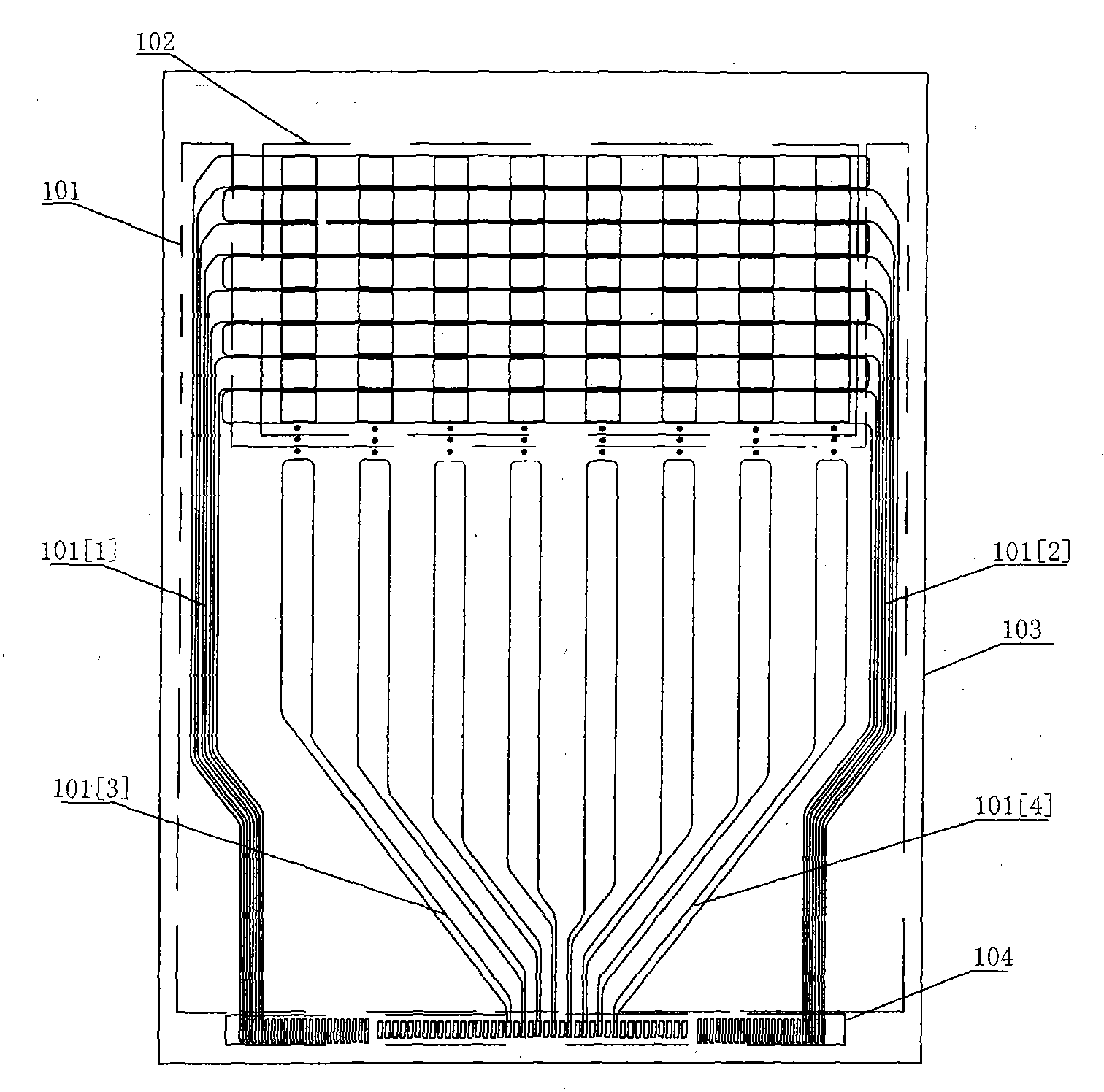

[0043] Such as image 3 , Figure 4 As shown, Embodiment 1 is an organic electroluminescent device with 96 rows×16 columns.

[0044] The odd-numbered row leads 401[1] and even-numbered row leads 401[2] are drawn out horizontally from the light-emitting area, and the left column leads 401[3] and right column leads 401[4] are drawn longitudinally. The ends of the leads are located at the lead extension 300 . After the lead 401[3] in the left column is bonded to the chip pin, its end extends to the left at 30° from the vertical direction after exceeding the chip pin; after the lead 401[4] in the right column is bonded to the chip pin, its end After the end exceeds the chip pins, it extends to the right at 30° from the vertical direction; after the odd-numbered row leads 401[1] are bonded to the chip pins, their ends exceed the chip pins and extend to the right at 30° from the vertical direction Extension: After the even-numbered row leads 401[2] are bonded to the chip pins, th...

Embodiment 2

[0053] Such as Figure 5 As shown, Embodiment 2 is also an organic electroluminescent device with 96 rows×16 columns. The odd-numbered row leads 501[1] and even-numbered row leads 501[2] are drawn laterally from the light-emitting area, and the left column leads 501[3] and right column leads 501[4] are drawn longitudinally. The ends of the leads are located at the lead extension 500 . After the left column lead 501[3] is bonded to the chip pin, its end extends to the left at 45° from the vertical direction after exceeding the chip pin; after the right column lead 501[4] is bonded to the chip pin, its end After the end exceeds the chip pins, it extends to the right at 45° from the vertical direction; after the odd-numbered row leads 501[1] are bonded to the chip pins, their ends exceed the chip pins and extend to the left at 45° from the vertical direction Extension: After the even-numbered row leads 501[2] are bonded to the chip pins, their ends extend to the right at 45° fr...

Embodiment 3

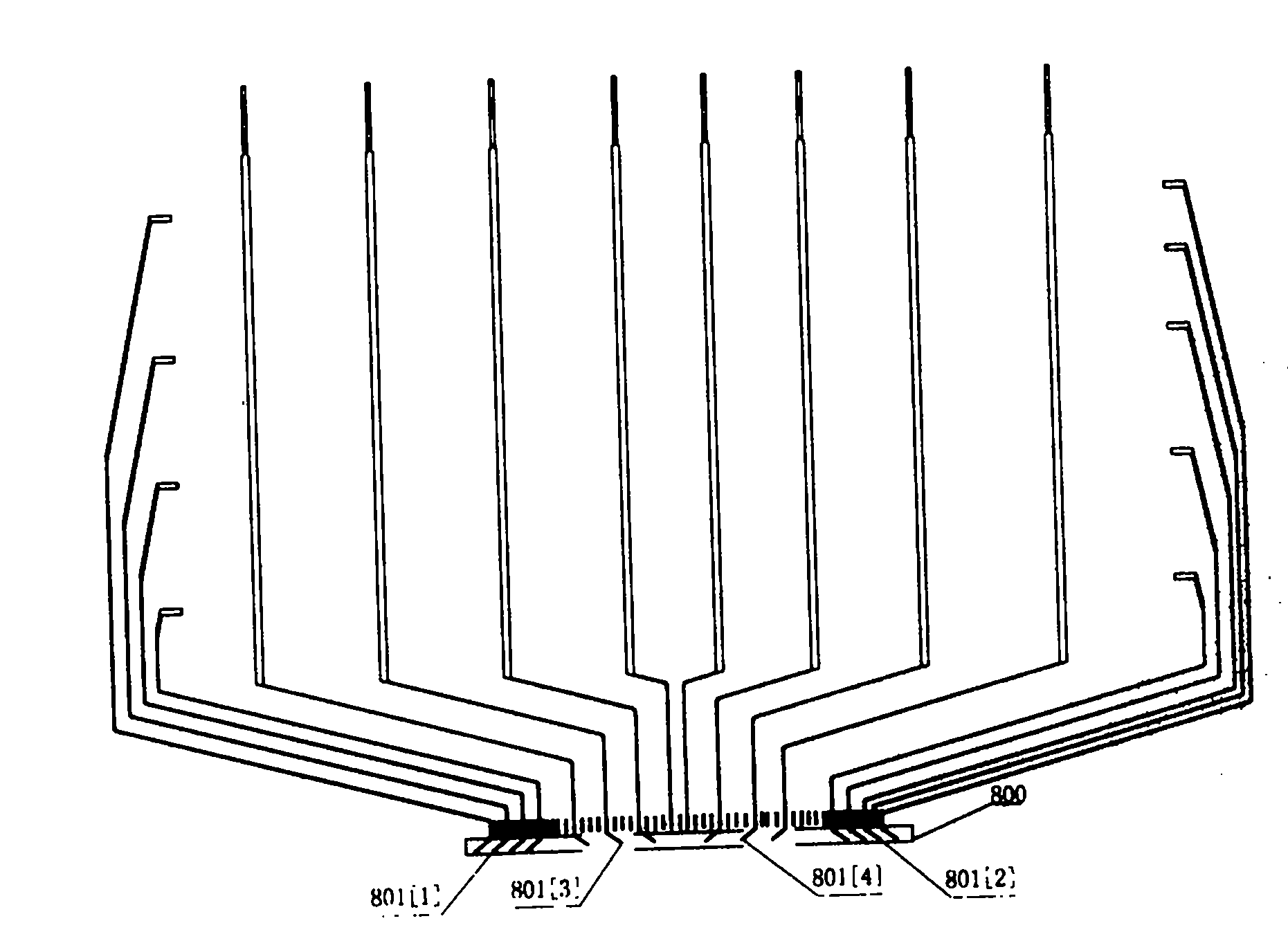

[0057] Such as Figure 6 , Figure 7 As shown, Embodiment 3 is an organic electroluminescent device with 64 rows×128 columns. The odd-numbered row leads 701[1] and even-numbered row leads 701[2] are drawn laterally from the light-emitting area, and the left column leads 701[3] and right column leads 701[4] are drawn longitudinally. The ends of the leads are located at the lead extension 700 . After the left-column lead 701[3] is bonded to the chip pin, its end extends to the right at 60° from the vertical direction after exceeding the chip pin; after the right-column lead 701[4] is bonded to the chip pin, its end After the end exceeds the chip pins, it extends to the left at 60° from the vertical direction; after the odd-numbered row leads 701[1] are bonded to the chip pins, their ends exceed the chip pins and extend to the right at 60° from the vertical direction Extension: After the even-numbered row leads 701[2] are bonded to the chip pins, their ends extend to the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com