Hyperbranched silane modified polyurethane composite polysiloxane antifouling paint and preparation method thereof

A technology of hyperbranched silane and polysiloxane, used in polyurea/polyurethane coatings, antifouling/underwater coatings, anti-corrosion coatings, etc. effect and other problems, to achieve the effect of overcoming poor adhesion, high adhesion and excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

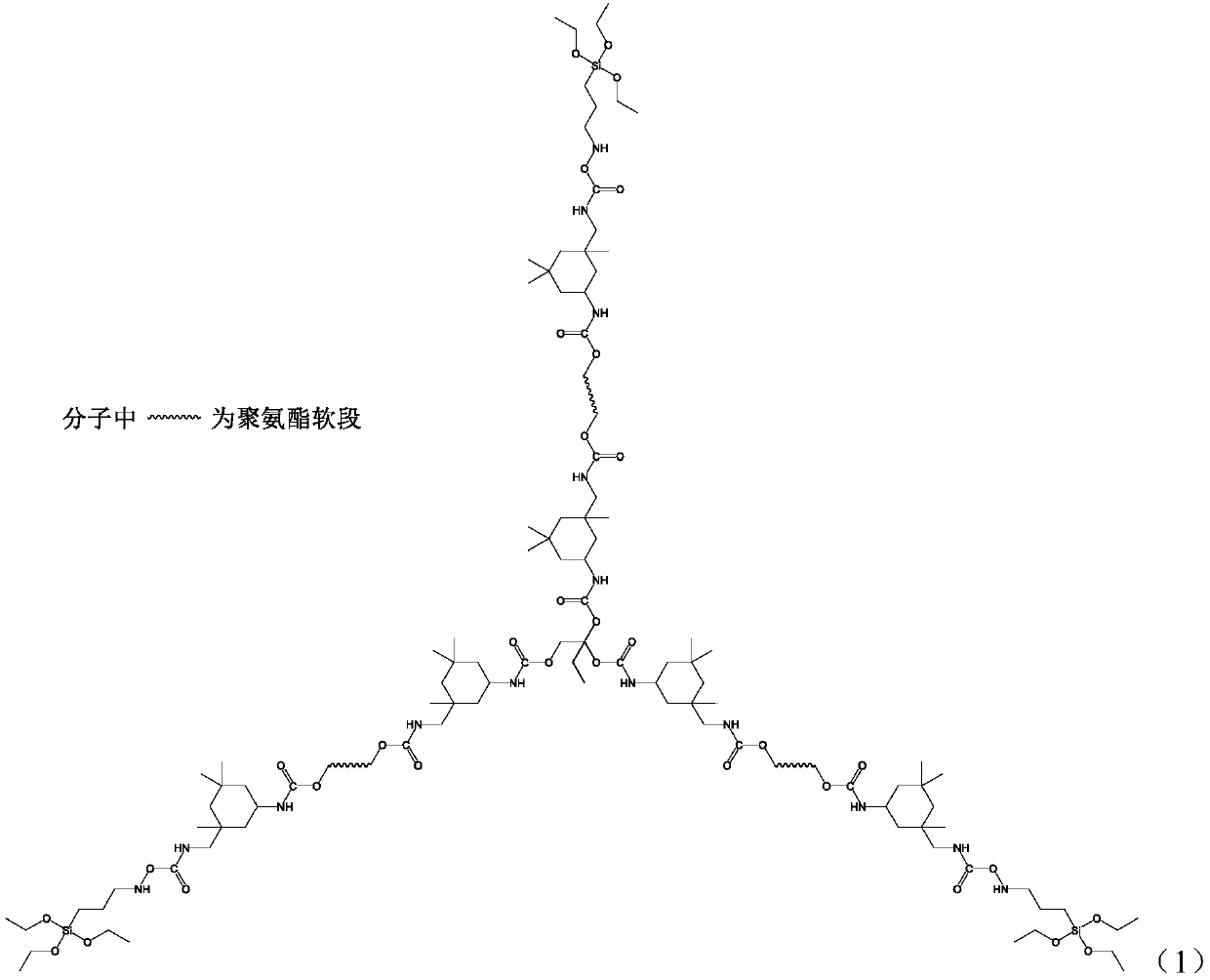

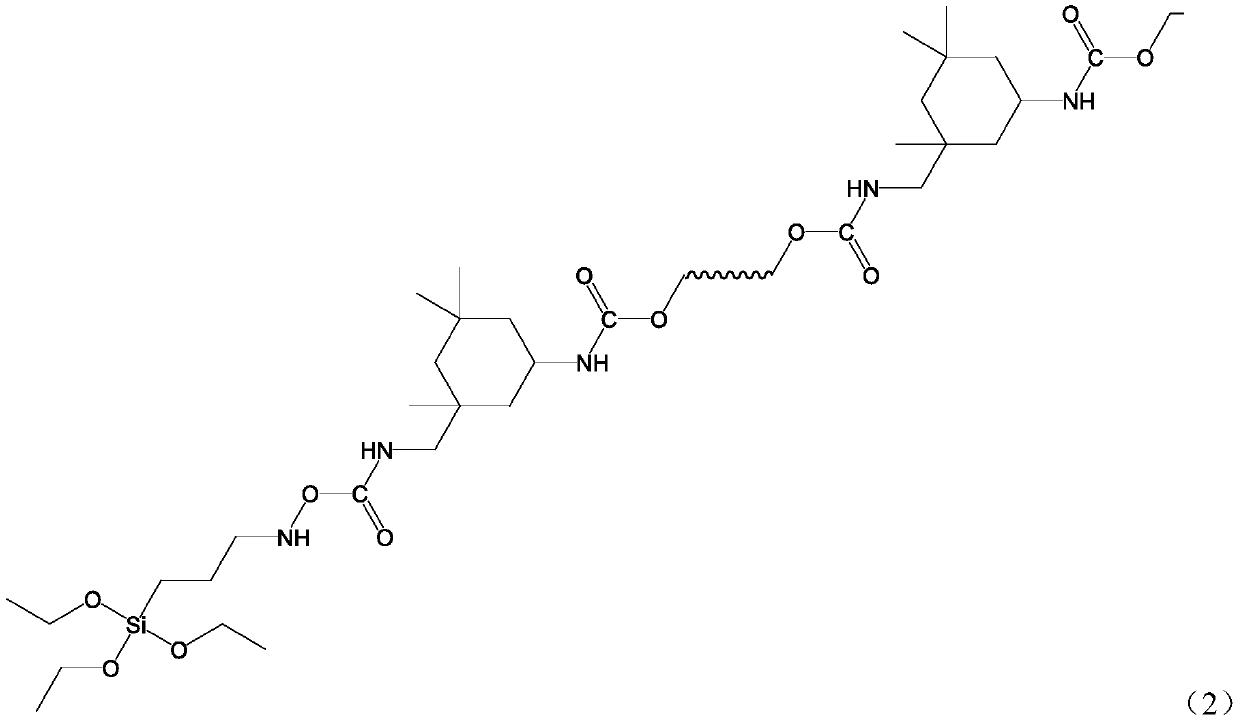

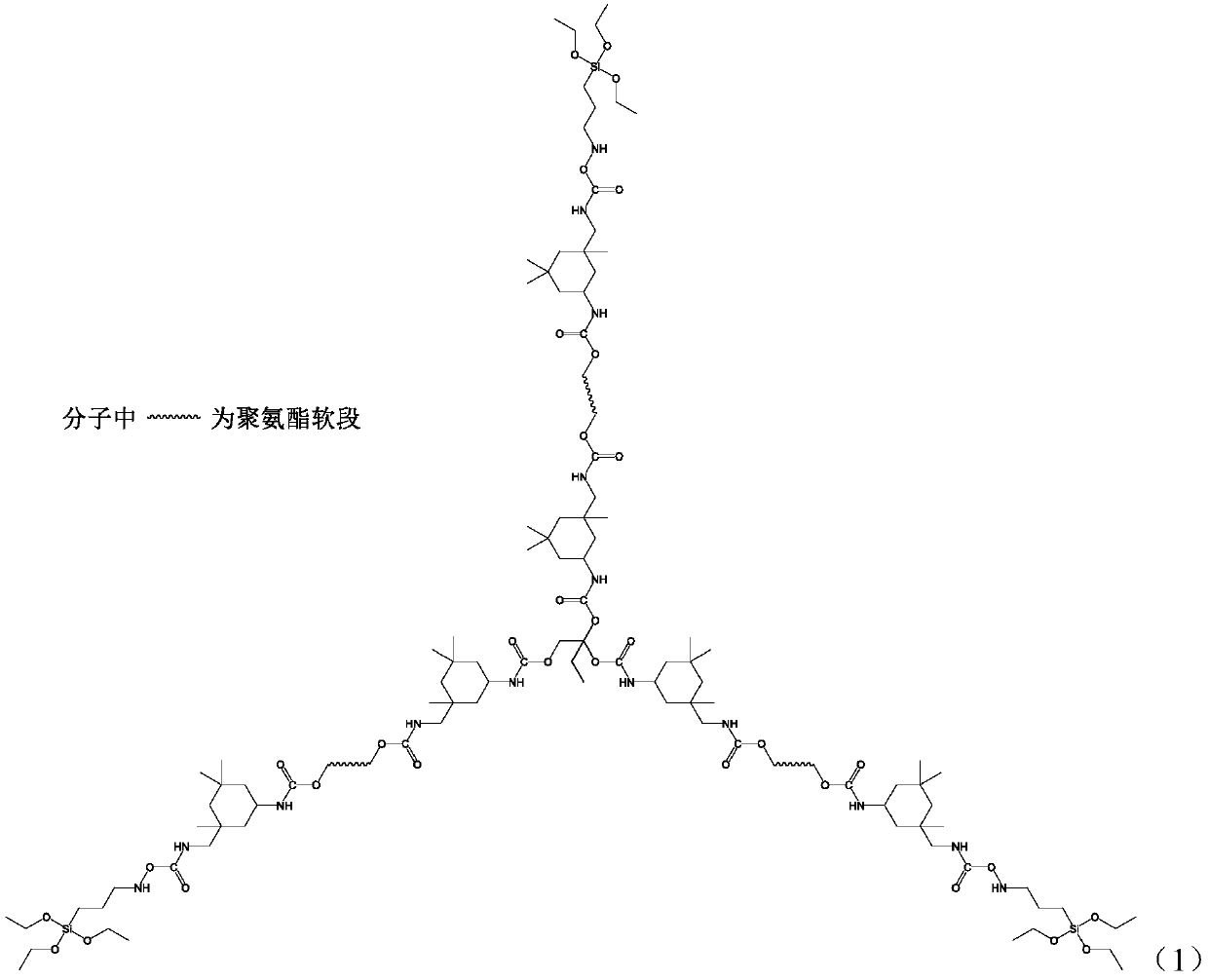

[0058] 1. Preparation of hyperbranched silane modified polyurethane

[0059] Use hydroxyl-terminated polysiloxane with a weight-average molecular weight of 500 or 1000 and polytetrahydrofuran ether diol with a weight-average molecular weight of 500 or 1000 as the polyurethane soft segment, and take hydroxyl-terminated polysiloxane at a molar ratio of 2:1 to 1:2. Alkanes and polytetrahydrofuran ether glycol, mixed uniformly; then blended with polyurethane hard segment, polyurethane hard segment is one or both of isophorone diisocyanate or diphenylmethane diisocyanate, control the group NCO of isocyanate The molar ratio of the hydroxyl group OH in the hydroxyl-containing polyurethane soft segment is 1.8-2.5:1; then add an organic tin or organic bismuth catalyst, the weight of the catalyst is 0.2% of the total weight of the polyurethane soft segment and polyurethane hard segment, at 85 ℃ for 5 hours; add trimethylolpropane chain extender, and control the amount of chain extender ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com