A kind of preparation method of polyurea waterproof coating applied to concrete surface

A concrete surface and waterproof coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor leveling effect, poor water resistance, and poor adhesion of concrete substrates on the coating film surface, so as to improve the binding force, The effect of water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

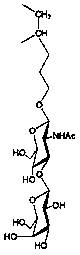

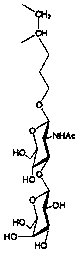

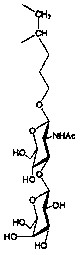

[0027] The first step, preparation of modifying agent: by weight, dissolve 22 parts of components shown in formula (I) in 60 parts of ethyl acetate, then add 0.5 parts of strong oxidizing agent H 5 IO 6 , carry out the oxidation reaction under the condition of avoiding light, the reaction temperature is 20°C, and the reaction time is 0.3h. After the reaction is completed, the solvent is distilled off under reduced pressure to obtain the aldehyde modified modifier;

[0028] (I);

[0029] Step 2, by weight, 45 parts of TDI (toluene-2,4-diisocyanate), 20 parts of polyether E-210, 12 parts of DMPA (2,2-dihydroxypropionic acid), 8 parts of alkoxy silicone oil Mix evenly, add 0.5 part of dibutyltin dilaurate to carry out the first reaction, then add 2 parts of the first chain extender neopentyl glycol to carry out the second reaction, the reaction temperature for the first and second time is 70 ℃, the first reaction time is 2h, the second reaction time is 1h, and then add 5 part...

Embodiment 2

[0034] The first step, the preparation of modifier: by weight, dissolve 45 parts of components shown in formula (I) in 95 parts of ethyl acetate, then add 1 part of strong oxidizing agent H 5 IO 6 , carry out the oxidation reaction under the condition of avoiding light, the reaction temperature is 30°C, and the reaction time is 1h. After the reaction is completed, the solvent is distilled off under reduced pressure to obtain the formylated modifier;

[0035] (I);

[0036] Step 2, by weight, 50 parts of TDI (toluene-2,4-diisocyanate), 25 parts of polyether E-210, 20 parts of DMPA (2,2-dihydroxypropionic acid), 12 parts of alkoxy silicone oil Mix evenly, add 1 part of dibutyltin dilaurate to carry out the first reaction, then add 8 parts of the first chain extender neopentyl glycol to carry out the second reaction, the reaction temperature for the first and second time is 90 ℃, the first reaction time is 4h, the second reaction time is 3h, then add 12 parts of ethyl acetate ...

Embodiment 3

[0041] The first step, the preparation of modifier: by weight, 35 parts of components shown in formula (I) are dissolved in 75 parts of ethyl acetate, then add 0.8 parts of strong oxidizing agent H 5 IO 6 , carry out the oxidation reaction under the condition of avoiding light, the reaction temperature is 25°C, and the reaction time is 0.7h. After the reaction is completed, the solvent is distilled off under reduced pressure to obtain the aldehyde modified modifier;

[0042] (I);

[0043] Step 2, by weight, 47 parts of TDI (toluene-2,4-diisocyanate), 22 parts of polyether E-210, 18 parts of DMPA (2,2-dihydroxypropionic acid), 10 parts of alkoxy silicone oil Mix evenly, add 0.8 part of dibutyltin dilaurate to carry out the first reaction, then add 5 parts of the first chain extender neopentyl glycol to carry out the second reaction, the reaction temperature of the first and second time is 75 ℃, the first reaction time is 3h, the second reaction time is 2h, then add 10 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com