Nano composite material applied to toe cap production and preparation method thereof

A technology for nano-composite materials and toe caps, which is applied in the field of nano-composite materials and their preparation, can solve the problems of enhanced dispersion of mechanical properties, poor wear resistance, low strength, etc., and achieves improved compatibility, good wear resistance, Good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

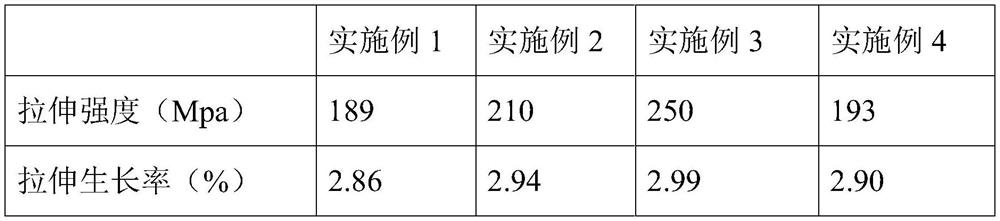

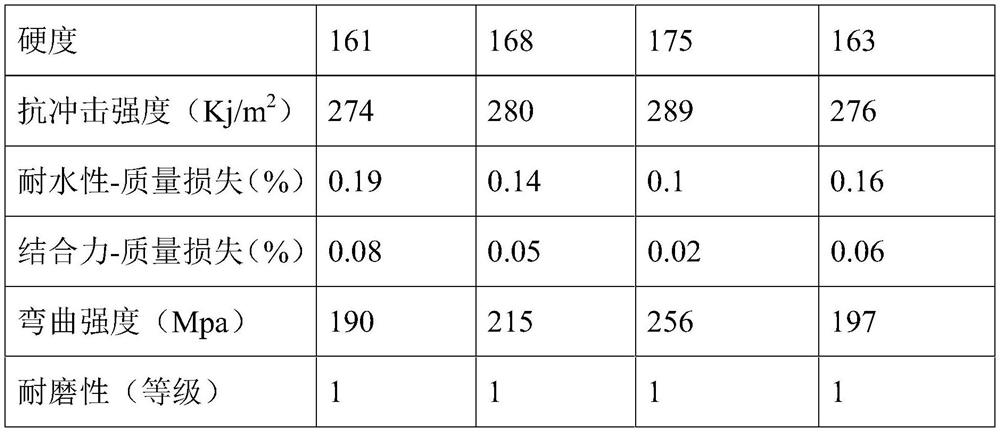

Examples

Embodiment 1

[0036] Embodiment 1 of the present invention provides a kind of nanocomposite material that is applied to shoe head production, comprises following raw material in parts by weight:

[0037] 20 parts of graphene, 10 parts of carbon nanotubes, 50 parts of fiber composition, 5 parts of silane coupling agent, 2 parts of acetic acid, 40 parts of acrylate rubber, 1 part of dispersant, 100 parts of polyethylene resin, 10 parts of nano-silicon carbide , 5 parts of calcium stearate, 5 parts of zinc stearate, 10 parts of talcum powder, 10 parts of modified boron nitride, 60 parts of curing agent.

[0038] The preparation method of nanocomposite material comprises the following steps:

[0039] (1) Prepare materials;

[0040] (2) Graphene is prepared into graphene oxide by Hummers method;

[0041] (3) immerse graphene oxide, carbon nanotubes, and nano-silicon carbide in a silane coupling agent, and react at 80-90°C for 1 hour;

[0042] (4) Put the mixture obtained in step (3) and groun...

Embodiment 2

[0053] Embodiment 2 of the present invention provides a kind of nanocomposite material that is applied to shoe head production, comprises following raw material in parts by weight:

[0054] 30 parts of graphene, 15 parts of carbon nanotubes, 80 parts of fiber composition, 8 parts of silane coupling agent, 3 parts of acetic acid, 60 parts of acrylate rubber, 3 parts of dispersant, 120 parts of polyethylene resin, 15 parts of nano-silicon carbide , 8 parts of calcium stearate, 8 parts of zinc stearate, 15 parts of talcum powder, 15 parts of modified boron nitride, and 70 parts of curing agent.

[0055] The preparation method of nanocomposite material comprises the following steps:

[0056] (1) Prepare materials;

[0057] (2) Graphene is prepared into graphene oxide by Hummers method;

[0058] (3) immerse graphene oxide, carbon nanotubes, and nano-silicon carbide in a silane coupling agent, and react at 85°C for 1.5h;

[0059] (4) Put the mixture obtained in step (3) and groun...

Embodiment 3

[0070] Embodiment 3 of the present invention provides a kind of nanocomposite material that is applied to shoe head production, comprises following raw material by weight part:

[0071] 40 parts of graphene, 20 parts of carbon nanotubes, 100 parts of fiber composition, 10 parts of silane coupling agent, 5 parts of acetic acid, 80 parts of acrylate rubber, 5 parts of dispersant, 150 parts of polyethylene resin, 20 parts of nano silicon carbide , 10 parts of calcium stearate, 10 parts of zinc stearate, 20 parts of talcum powder, 20 parts of modified boron nitride, and 80 parts of curing agent.

[0072] The preparation method of nanocomposite material comprises the following steps:

[0073] (1) Prepare materials;

[0074] (2) Graphene is prepared into graphene oxide by Hummers method;

[0075] (3) immerse graphene oxide, carbon nanotubes, and nano-silicon carbide in a silane coupling agent, and react at 90°C for 2 hours;

[0076] (4) Put the mixture obtained in step (3) and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com