Coated filter material

A filter material and film-coated technology, which is applied in the field of non-woven film-coated filter material products, can solve the problems of poor bending resistance of glass fibers and easy breakage of filter materials, and achieve easy dust removal, excellent mechanical properties, and high collection efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Embodiment: the 260g / m in the present invention 2 The spunbonded nonwoven filter cloth (raw material is polyester or polypropylene) is covered with a layer of polytetrafluoroethylene (PTFE) film, and the fibers constituting the spunbonded nonwoven filter cloth are sheath-core bicomponent fibers. The melting point is lower than that of the core fiber).

[0016] The thickness of the polymer microporous membrane is between 5-150 μm, and the porosity is above 95%.

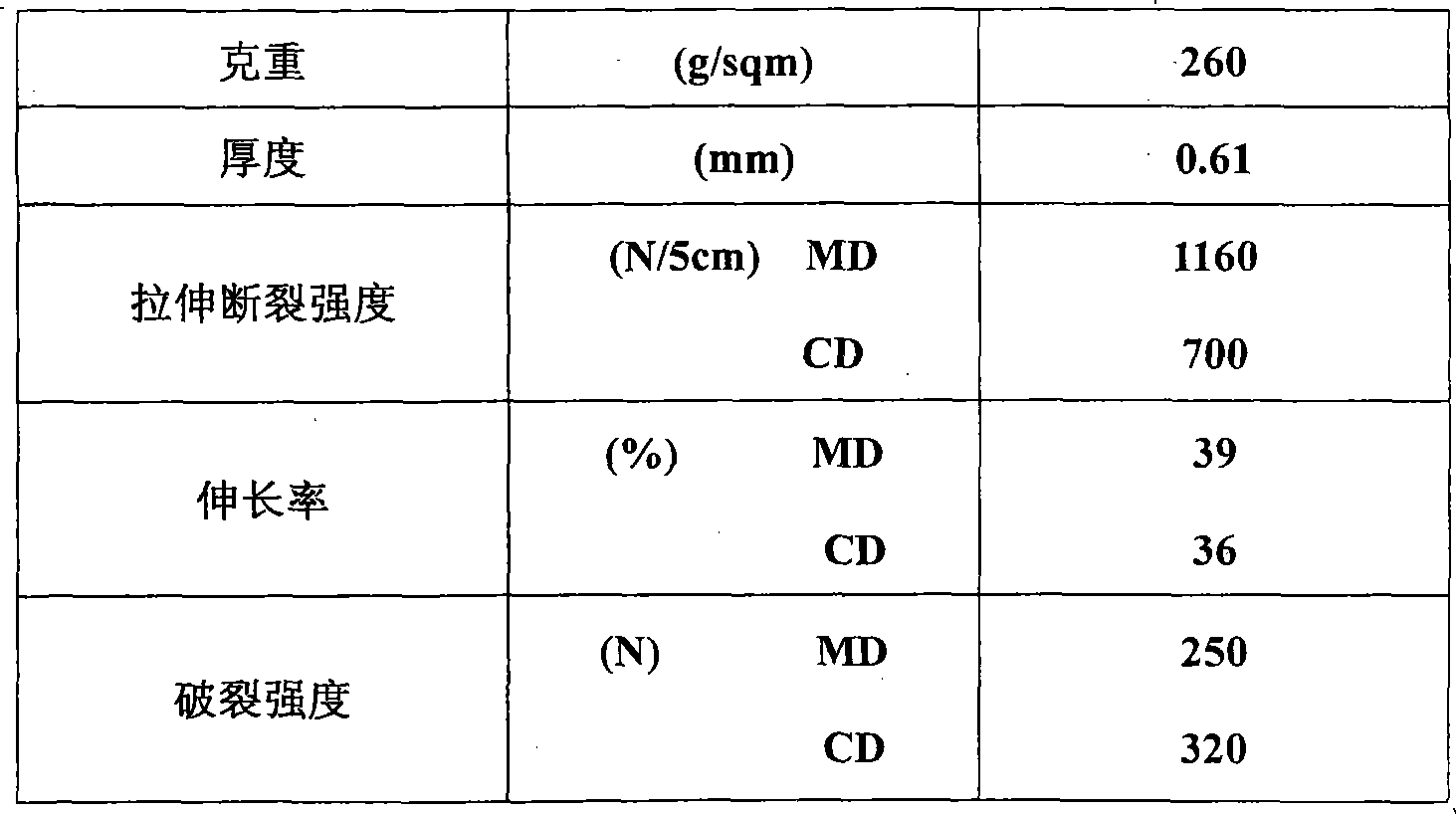

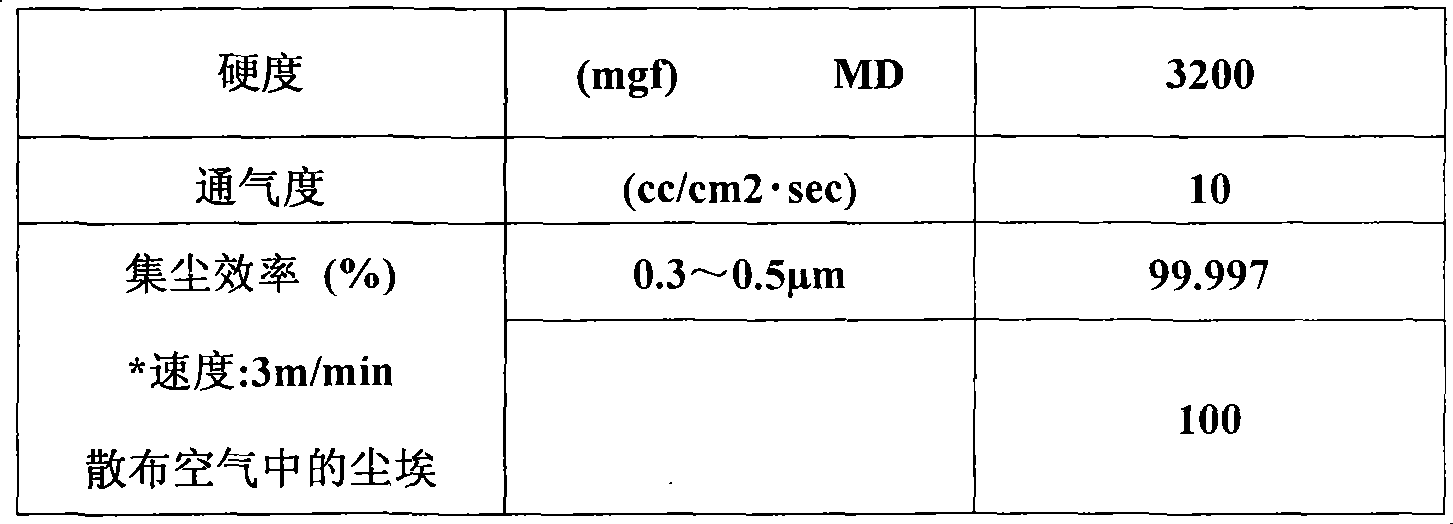

[0017] Its performance parameters are as follows:

[0018]

[0019]

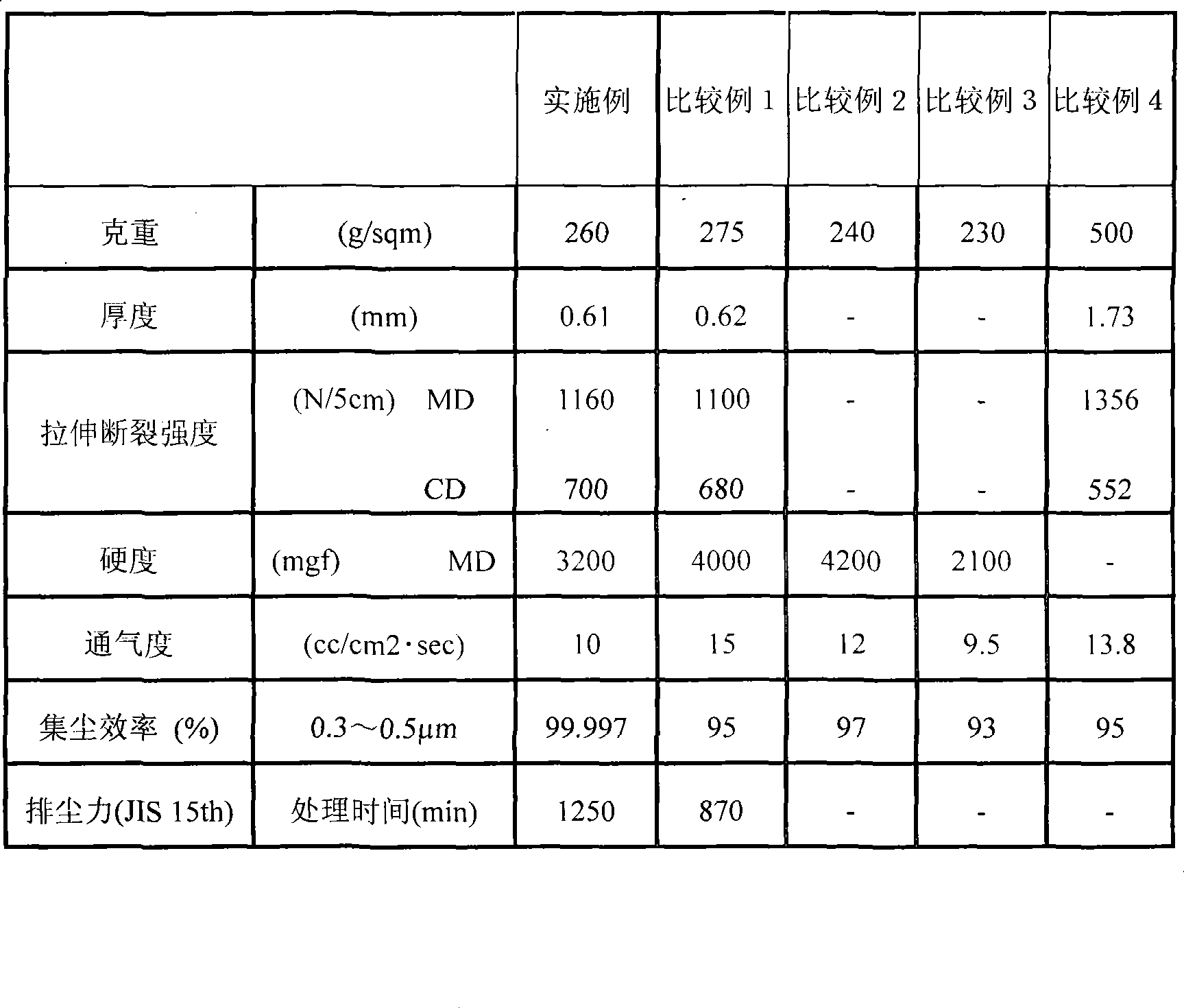

[0020] Comparison with other product performance:

[0021] Above-mentioned embodiment and other product performance comparison table

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com