Molded surface fastener and cushion body formed integrally with the molded surface fastener

A technology for molding surfaces and fasteners, used in fasteners, clothing, applications, etc., to solve problems such as difficulty in obtaining adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

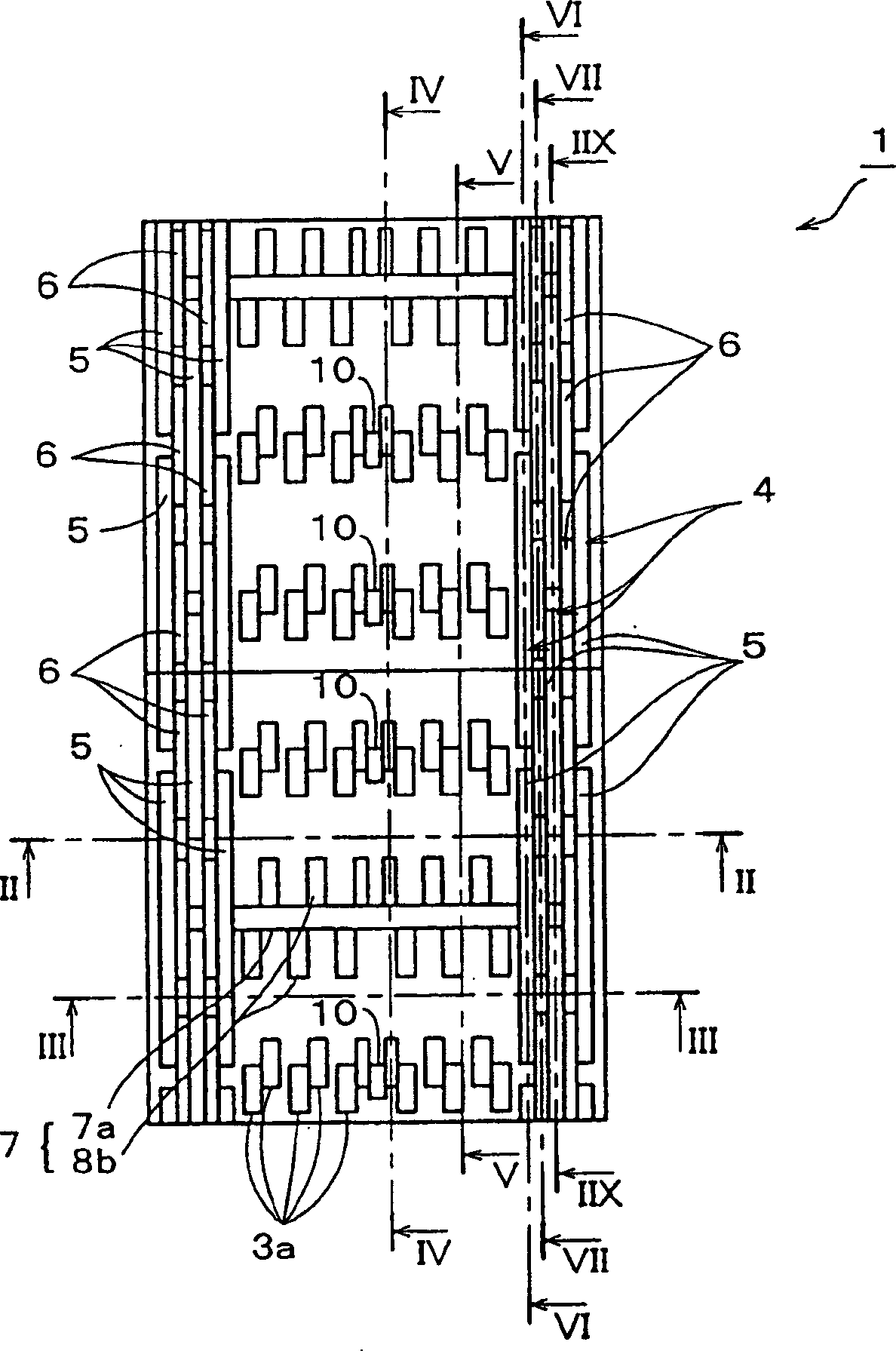

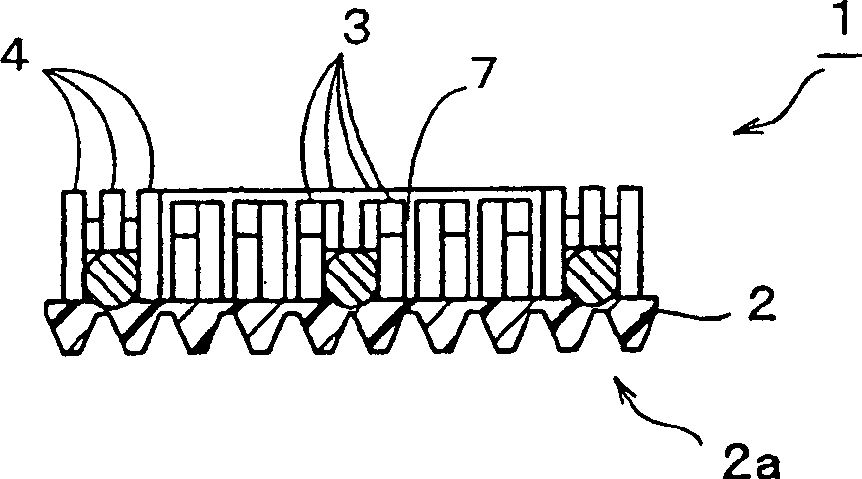

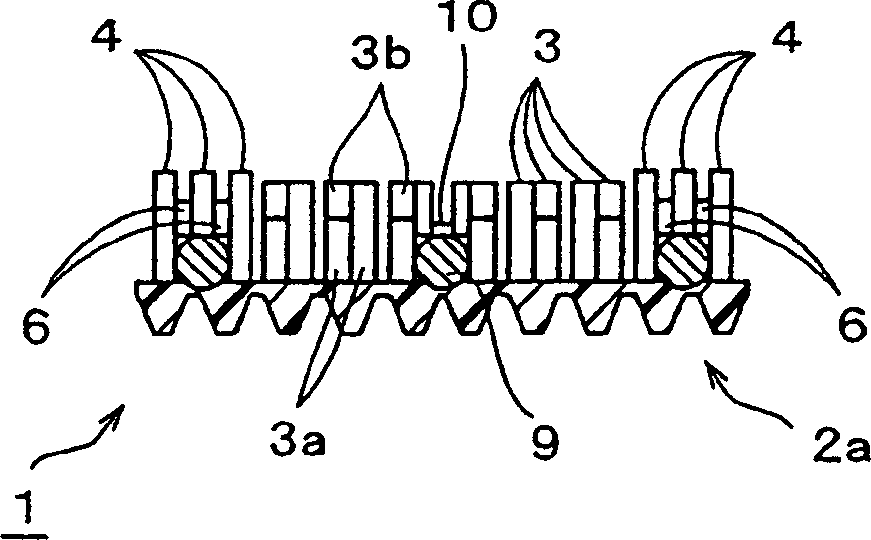

[0041] Hereinafter, some embodiments of the present invention will be described in detail with reference to the accompanying drawings. Figure 1-8 A first embodiment of the present invention is shown.

[0042] like figure 1 As shown in , many engaging elements 3 in a hook shape are on one surface of the flat-shaped base member 2 of the strip-shaped molded surface fastener 1 of this embodiment except for two edge portions. Formed in the joining element forming area, three rows of longitudinal wall portions 4 are erected as the first resin intrusion preventing means of the present invention along one longitudinal direction on both side edge portions of the base member 2 so that they are line-like in parallel ground layout. like Figure 1-3 , As shown in 6 and 8, these longitudinal wall portions 4 are constituted by a plurality of partition walls 5 separated at a predetermined pitch (Pitch) along the longitudinal direction. The three rows of longitudinal wall sections 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com