Large-area TiB-TiC reinforced titanium-based composite coating and preparation method thereof

A composite coating and large-area technology, applied in the direction of heating inorganic powder coating, etc., can solve the problems of easily polluting the surface of the substrate, affecting the fusion of the substrate and the coating, and achieve the effect of reducing the tendency of crack formation and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

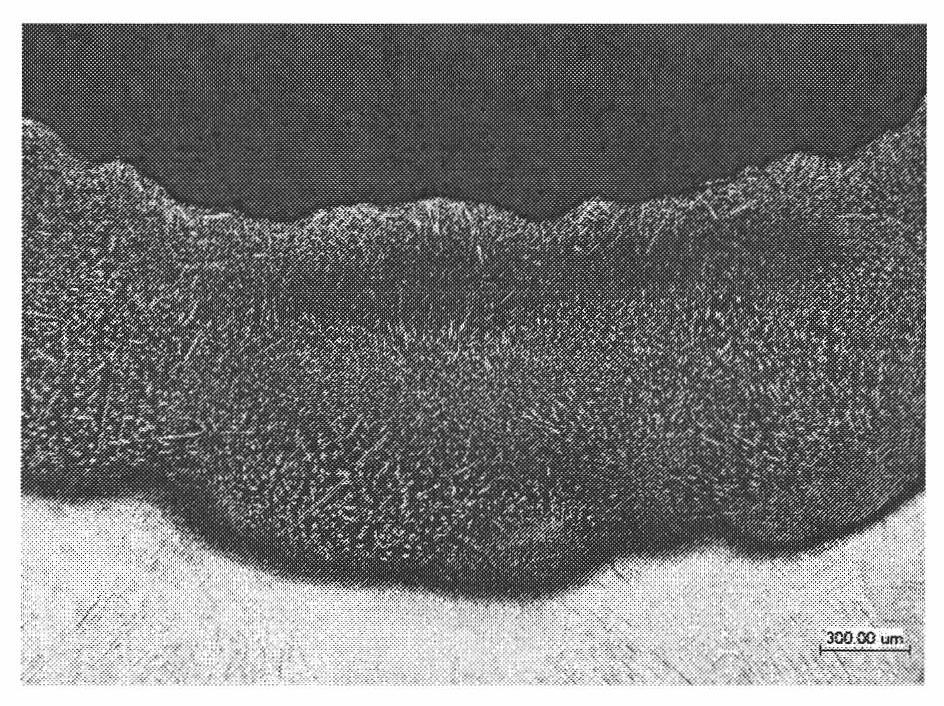

[0044] A large-area TiB-TiC reinforced titanium-based composite coating, the composition (weight %) of the components required to prepare the coating is 83% Ti, 7% B 4 C, 4% Al, 3% Nano TiC, 3% Y 2 o 3 .

[0045] The preparation process of the above-mentioned large-area TiB-TiC reinforced titanium-based composite coating includes the following steps:

[0046] (1) Ti, B 4 C, nano TiC and rare earth oxide powder Y 2 o 3 The precursor is uniformly mixed through a ball mill;

[0047] (2) On the surface of the Ti6Al4V substrate, a layer of adhesive is brushed to increase the bonding strength between the pre-coating layer and the substrate;

[0048] (3) A certain amount of mixed powder is evenly placed on the surface of Ti6Al4V coated with binder, and then the mixed powder is densified and the surface is smoothed by a pressure of 5 MPa to obtain a pre-coating layer with a thickness of about 0.8 mm.

[0049](4) For the above-mentioned pre-assembled coating, a light source with...

Embodiment 2

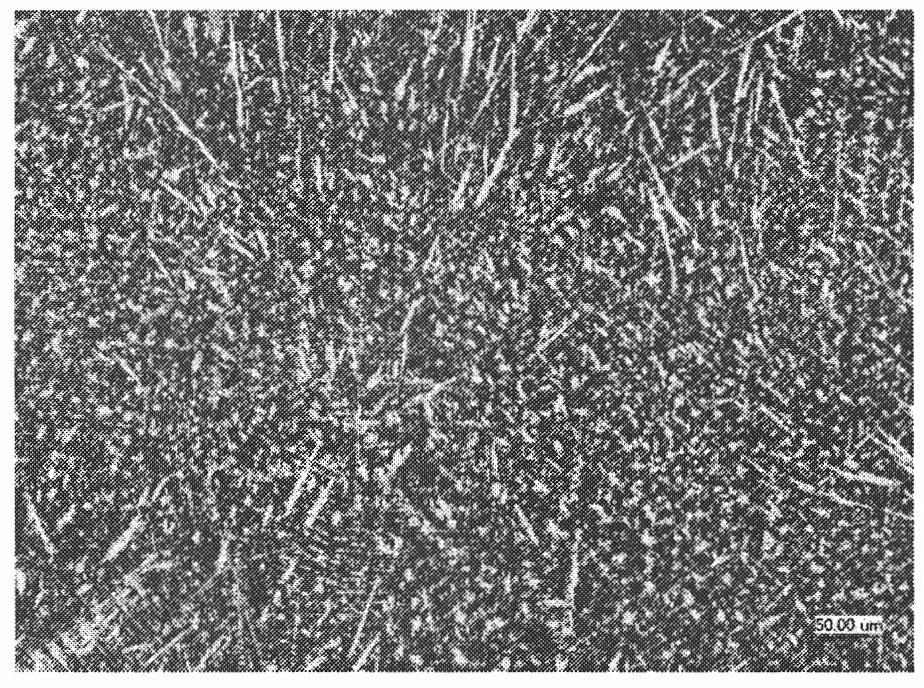

[0054] A large-area TiB-TiC reinforced titanium-based composite coating, the composition (weight %) of the components required to prepare the coating is 86% Ti, 5% B 4 C, 2% Al, 2% Nano TiC, 5% La 2 o 3 .

[0055] The preparation process of the above-mentioned large-area TiB-TiC reinforced titanium-based composite coating includes the following steps:

[0056] (1) Ti, B 4 C, nano TiC and rare earth oxide powder La 2 o 3 The precursor is uniformly mixed through a ball mill;

[0057] (2) On the surface of the Ti6Al4V substrate, a layer of adhesive is brushed to increase the bonding strength between the pre-coating layer and the substrate;

[0058] (3) A certain amount of mixed powder is evenly placed on the surface of Ti6Al4V coated with binder, and then the mixed powder is densified and the surface is smoothed by a pressure of 5 MPa to obtain a pre-coating layer with a thickness of about 0.8 mm.

[0059] (4) For the above-mentioned pre-assembled coating, a light source w...

Embodiment 3

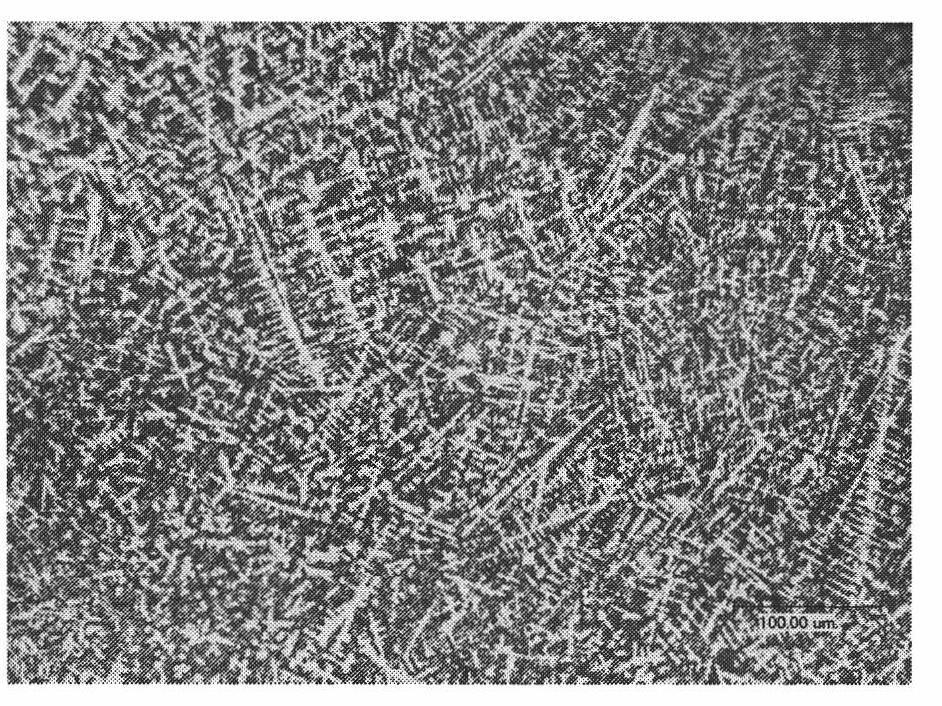

[0063] A large-area TiB-TiC reinforced titanium-based composite coating, the composition (weight %) of the components required to prepare the coating is 86% Ti, 5% B 4 C, 2% Al, 2% Nano TiC, 5% Nd 2 o 3 .

[0064] The preparation process of the above-mentioned large-area TiB-TiC reinforced titanium-based composite coating includes the following steps:

[0065] (1) Ti, B 4 C, nano TiC and rare earth oxide powder Nd 2 o 3 The precursor is uniformly mixed through a ball mill;

[0066] (2) On the surface of the Ti6Al4V substrate, a layer of adhesive is brushed to increase the bonding strength between the pre-coating layer and the substrate;

[0067] (3) Place a certain amount of mixed powder evenly on the surface of Ti6Al4V coated with binder, and then use a pressure of 5 MPa to densify the mixed powder and smooth the surface to obtain a pre-coating layer with a thickness of about 0.8mm

[0068] (4) For the above-mentioned pre-assembled coating, a light source with a power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com