Exothermic wire for bonding substrates

A technology of exothermic reaction and wire harness, which is applied in the field of exothermic wires connecting substrates, can solve the problems of degrading the separation of layers, difficulty in mass production, etc., and achieve the effects of high productivity, low cost, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

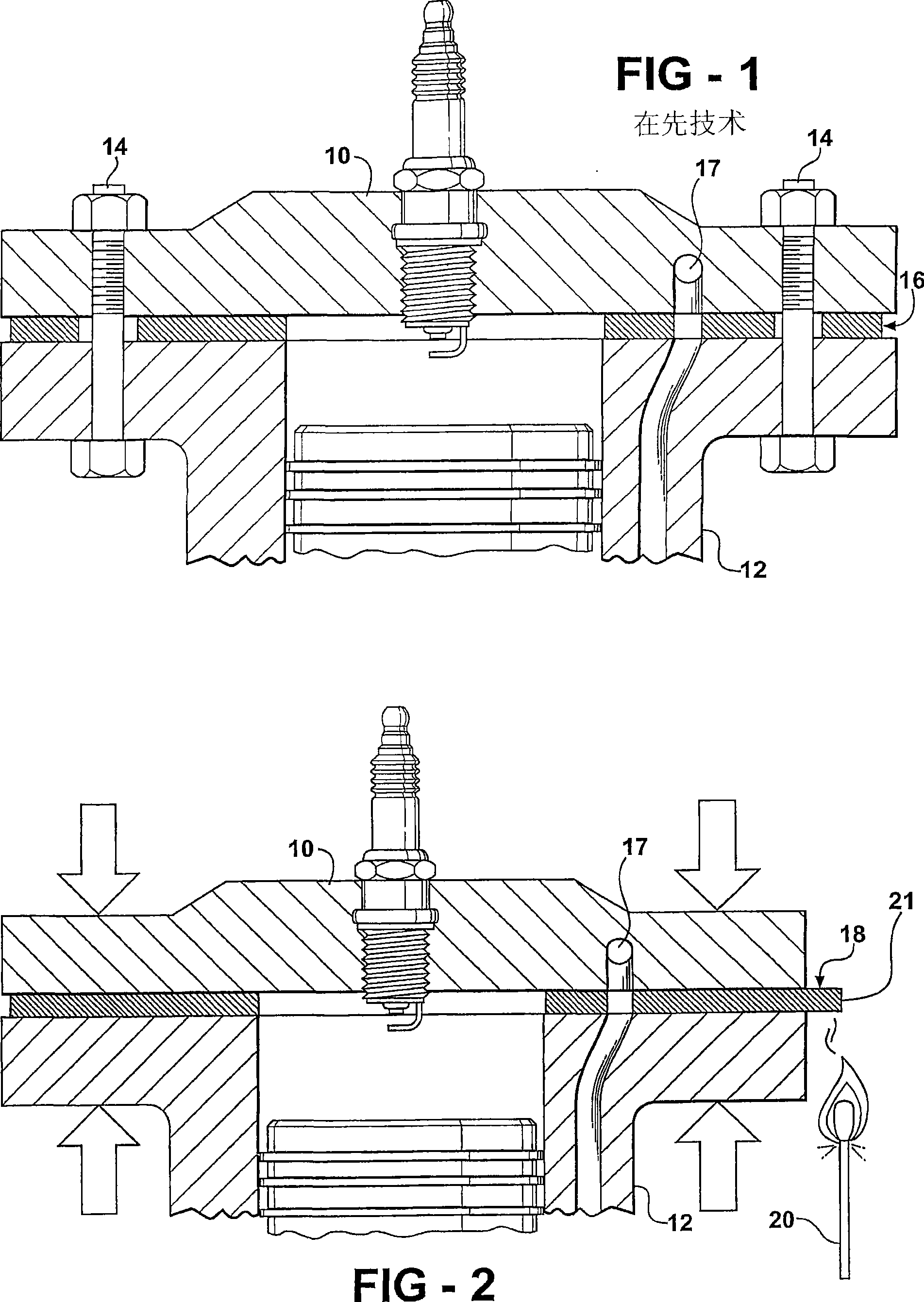

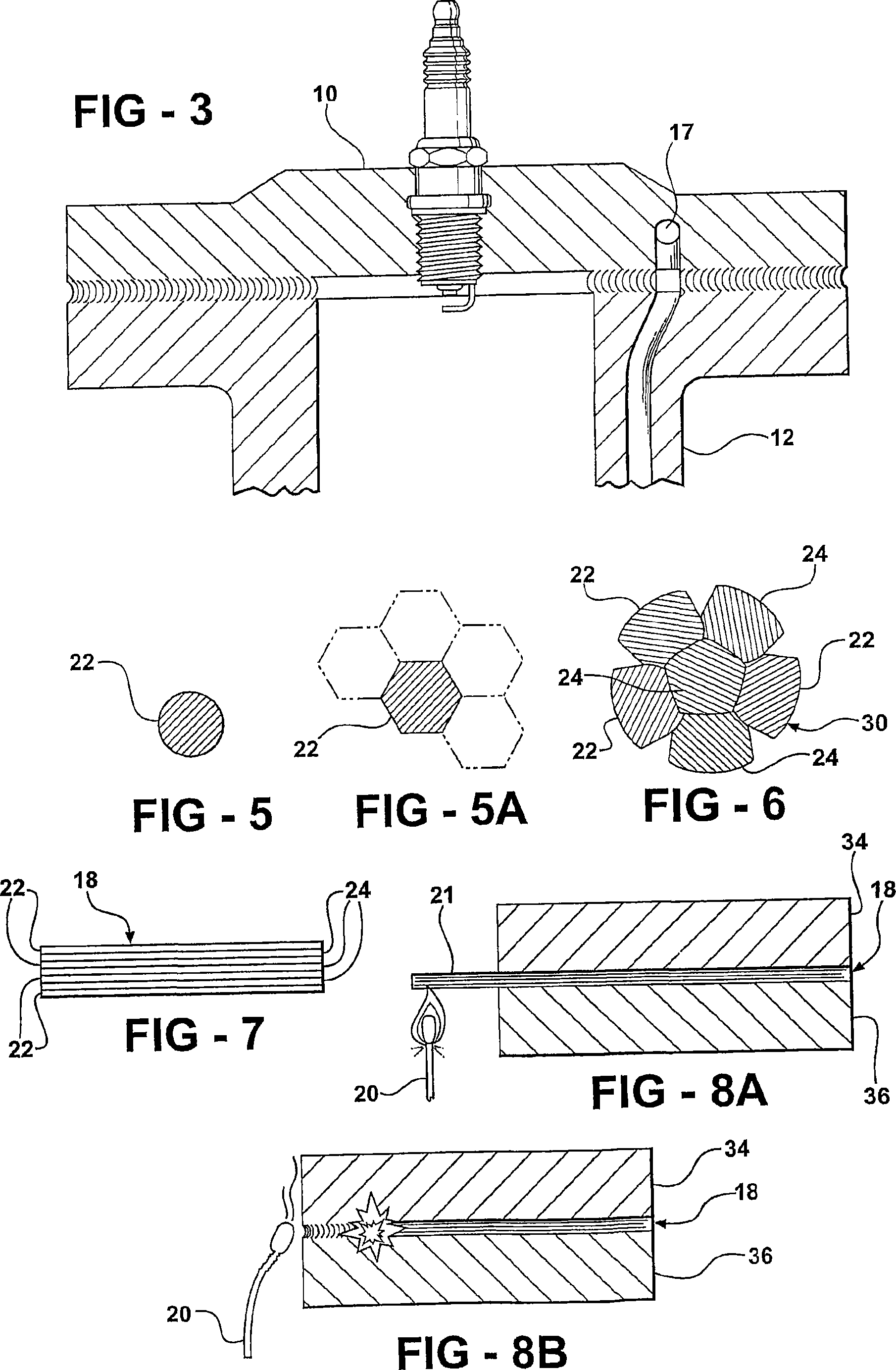

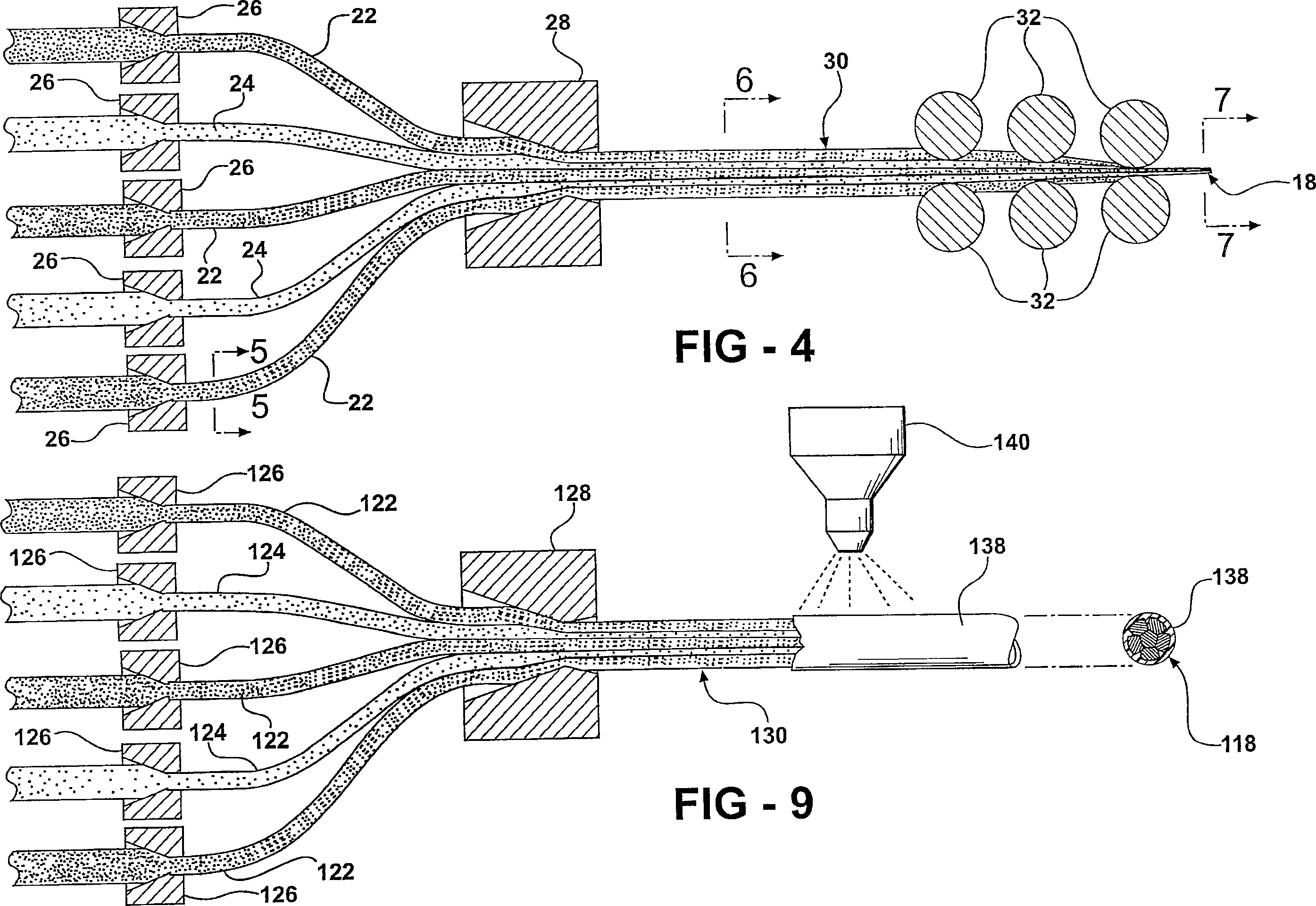

[0028] Referring to the drawings, wherein like numerals refer to like or corresponding parts throughout, a conventional internal combustion engine assembly is shown in FIG. 1 , including a cylinder head 10 attached to a cylinder block 12 by head bolts 14 . A gasket 16 is provided between the cylinder head 10 and the cylinder block 12 and is clamped under the pressure of the cylinder head bolts 14 . Gasket 16 seals internal pressure and fluid circulation within the cylinder bore to prevent leakage and maximize combustion efficiency.

[0029] In some internal combustion engine applications, it may be desirable to permanently seal the cylinder head 10 to the cylinder block 12 without the gasket 16 . Recalling the existing fixed cylinder head internal combustion engine, the cylinder head and the cylinder block form an inseparable whole, the internal combustion engine thus formed has the advantage of saving the cost of the gasket 16 and avoiding it as a leakage path over time. How...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com