Lithium ion battery and electrolyte thereof

A technology of lithium ion battery and electrolyte, applied in the field of lithium ion battery and its electrolyte, can solve the problems of battery impedance increase, thickness expansion, electrolyte oxidation reaction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

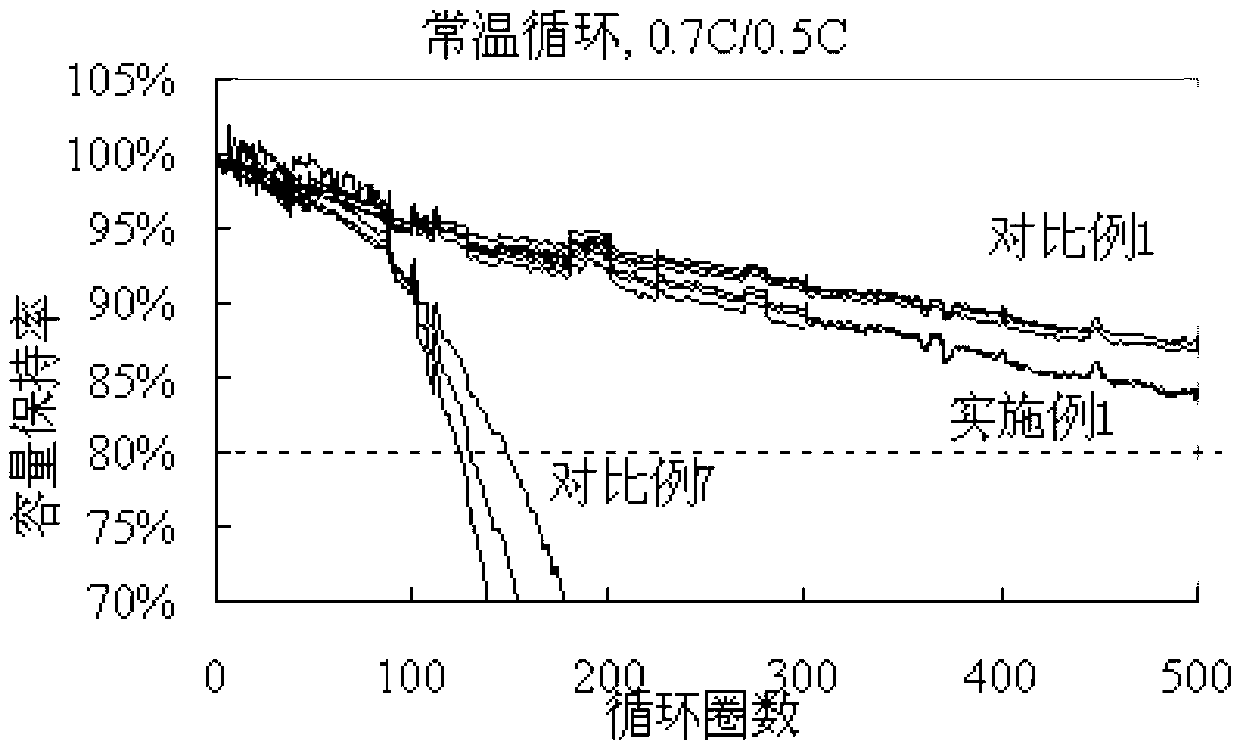

Embodiment 1

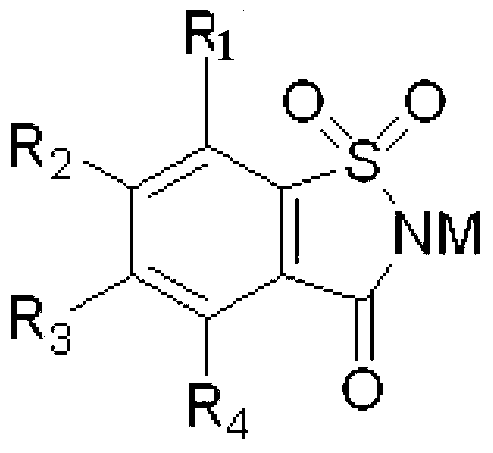

[0029] Electrolyte preparation: Mix propylene carbonate (PC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) at a mass ratio of 1:1:1 to form 1mol / L LiPF 6 Electrolyte, then, add and account for electrolyte mass ratio and be 3% o-benzoylsulfonimide lithium (structural formula is as follows), mass ratio is 2% glutaronitrile (GLN), mass ratio is 0.5% fluorinated Ethylene carbonate (FEC) and vinylene carbonate (VC) with a mass ratio of 2% were used to prepare lithium-ion battery electrolyte.

[0030]

[0031] The preparation of the positive electrode sheet: the positive electrode active material lithium cobaltate (LiCoO 2 ), the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) are fully stirred and mixed in the N-methylpyrrolidone solvent system at a mass ratio of 96:2:2, and coated on the positive electrode current collector Al foil. After drying and cold pressing, the positive electrode sheet was obtained.

[0032] Preparation of ne...

Embodiment 2

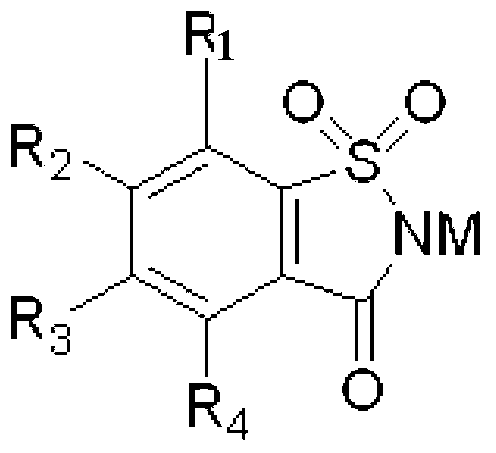

[0036] Electrolyte preparation: Mix propylene carbonate (PC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) at a mass ratio of 1:1:1 to form 1mol / L LiPF 6 Electrolyte, then add sodium methyl phthaloylsulfonimide (structural formula as follows) accounting for 1.5% of the mass ratio of the electrolyte, adiponitrile (ADN) with a mass ratio of 1%, fluorine with a mass ratio of 2% Ethylene carbonate (FEC) and vinylene carbonate (VC) with a mass ratio of 2% are used to prepare the lithium-ion battery electrolyte.

[0037]

[0038] In Example 2, the preparation of the positive electrode sheet, the negative electrode sheet, the separator, and the lithium-ion battery are basically the same as in Example 1, and will not be repeated here.

Embodiment 3

[0040] Electrolyte preparation: Mix propylene carbonate (PC), ethylene carbonate (EC) and ethyl methyl carbonate (EMC) at a mass ratio of 1:1:1 to form 1mol / L LiPF 6 Electrolyte, then add the potassium ethyl phthaloylsulfonimide (structural formula as follows) that accounts for 4% of the mass ratio of the electrolyte, the succinonitrile (SN) that is 6% by mass, and the fluorine that is 9% by mass Substituting ethylene carbonate (FEC), that is, the lithium-ion battery electrolyte is obtained.

[0041]

[0042] In Example 3, the preparation of the positive electrode sheet, the negative electrode sheet, the separator, and the lithium ion battery are basically the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com